Nov . 15, 2024 00:00 Back to list

roof rack for sheet materials factories

Roof Racks for Sheet Materials Factories An Essential Solution

In the realm of manufacturing, particularly within sheet materials factories, efficiency and safety are paramount. Sheet materials, such as plywood, metal sheets, and plastic panels, often require transportation to and from various workstations. This is where the necessity of roof racks becomes evident. Roof racks, traditionally associated with vehicles, have evolved into a vital component for factories handling large or heavy materials, enabling safer and more efficient operations.

Understanding Roof Racks

Roof racks are supportive structures mounted on the roofs of vehicles, designed to transport bulky items securely. They can also refer to specialized racks installed in factories to hold and organize sheet materials. Regardless of the application, the primary goal of a roof rack is to maximize space utilization and enhance the ease of moving materials.

In sheet materials factories, these racks are crucial for several reasons

1. Space Optimization Factories often face spatial constraints. By using roof racks, manufacturers can utilize vertical space effectively. This is particularly beneficial in environments where floor space is limited. With properly installed roof racks, sheet materials can be stored overhead, freeing up valuable ground space for other production activities.

2. Enhanced Organization Roof racks help maintain an organized workspace. With designated areas for different types of sheet materials, workers can quickly locate what they need without searching through piles of disorganized inventory. An organized workspace not only improves efficiency but also reduces the chances of accidents caused by clutter.

3. Improved Safety Safety is a significant concern in any manufacturing environment. Roof racks that securely hold sheet materials reduce the risk of materials falling or causing tripping hazards. Additionally, having a designated place for each type of material minimizes unnecessary handling, decreasing the chances of injuries among workers.

roof rack for sheet materials factories

4. Ease of Access In a factory setting, workers often require quick access to materials. Roof racks can be designed to allow easy loading and unloading of items, which is essential for maintaining workflow. Utilizing lifts or rolling systems in conjunction with roof racks can further enhance accessibility, allowing workers to move materials efficiently without straining or risking injury.

5. Cost-Effectiveness Investing in roof racks can be a cost-effective solution for production facilities. By optimizing storage space and improving efficiency, companies can see a return on investment through reduced operational costs and increased productivity. Furthermore, having a safe and organized workspace can reduce costs associated with accidents and workplace injuries.

Choosing the Right Roof Rack

When selecting roof racks for sheet materials factories, several factors should be considered

- Material The strength and durability of the rack material are critical. Steel or heavy-duty aluminum options are recommended to withstand the weight of sheet materials. - Design The design should cater to the specific types of sheet materials being stored. Custom racks can be designed to accommodate unique dimensions or weight limits. - Accessibility Consideration should be given to how workers will access the roof racks. Adequate ladders or lifts should be integrated to ensure materials can be handled safely. - Compatibility with Equipment The roof rack system should be compatible with any existing equipment, such as forklifts or hoists, to ensure seamless operations.

Conclusion

In conclusion, roof racks for sheet materials factories represent a vital investment towards enhancing operational efficiency, safety, and organization. As sheet material handling continues to grow in complexity, the integration of thoughtful storage solutions like roof racks will be indispensable for forward-thinking manufacturing facilities. By prioritizing the needs of the factory environment, manufacturers not only comply with safety regulations but also promote a culture of safety and efficiency that leads to sustained growth and success in a competitive industry.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

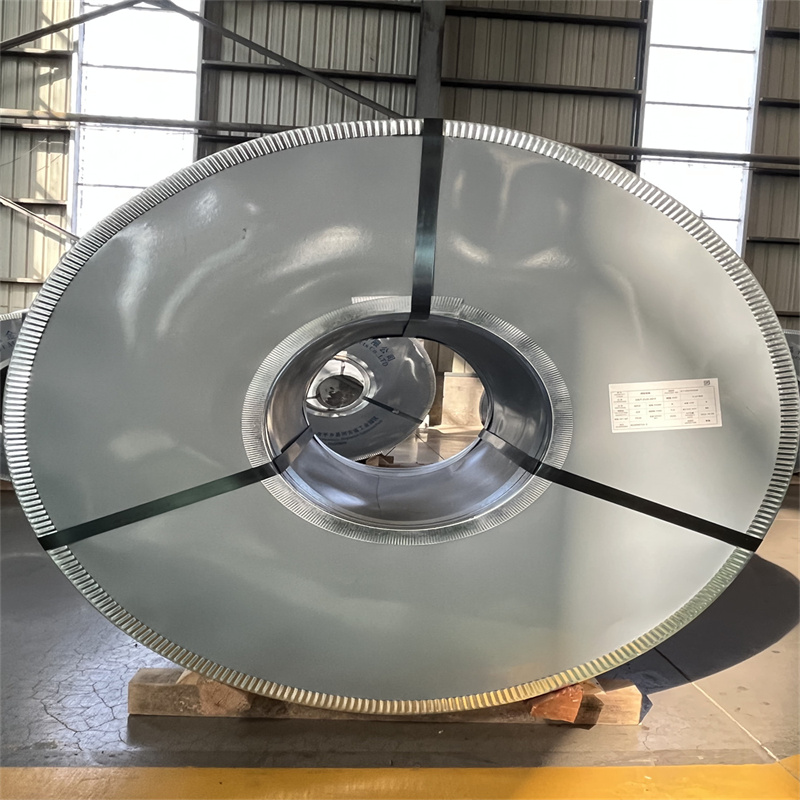

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025