Aug . 10, 2024 13:20 Back to list

Reliable Supplier of Metal Tin Boxes for All Your Packaging Needs and Creative Projects

The Rise of Metal Tin Box Suppliers A Comprehensive Overview

In an era where packaging plays a vital role in product presentation and preservation, metal tin boxes have emerged as a popular choice across various industries. From food and beverages to cosmetics and gift items, these containers are not only functional but also environmentally friendly and visually appealing. As the demand for metal tin boxes continues to grow, so does the importance of suppliers who specialize in this niche market.

Understanding Metal Tin Boxes

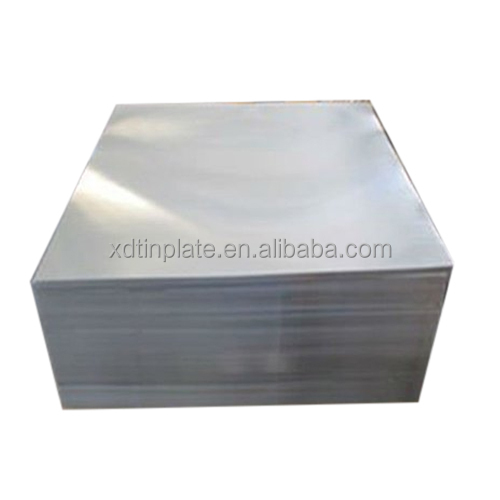

Metal tin boxes are made primarily of tinplate, a thin sheet of steel coated with tin to prevent corrosion. They provide excellent protection against external elements such as moisture, light, and air, making them ideal for items like cookies, candies, and even luxury goods. Their durability ensures that products remain fresh and retain their quality throughout their shelf life.

Moreover, tin boxes are recyclable, contributing to sustainability efforts and appealing to environmentally conscious consumers. With growing awareness about the impact of plastic packaging on the environment, many businesses are shifting towards metal options, thereby increasing the demand for metal tin box suppliers.

The Role of Suppliers in the Industry

Suppliers of metal tin boxes play a crucial role in supporting manufacturers and businesses looking for effective packaging solutions. They not only provide the raw materials needed for production but also assist in design and customization. A reputable supplier offers a range of services, including

1. Customization Options Many businesses require unique packaging to stand out in the market. Suppliers often offer custom sizes, shapes, and printed designs that cater to specific branding needs. This personalization can have a significant impact on consumer buying decisions.

metal tin box supplier

2. Quality Assurance A reliable supplier ensures that their metal tin boxes meet the necessary quality standards, which is paramount in industries such as food and pharmaceuticals. High-quality materials and manufacturing processes lead to safer, more durable products.

3. Competitive Pricing Given the competitive nature of the packaging industry, suppliers aim to keep costs low while maintaining quality. Businesses benefit from negotiating bulk purchase agreements that can lower overall expenses.

4. Logistics and Distribution A good supplier also provides efficient logistics solutions, ensuring timely delivery of products. This aspect is vital for businesses that work on tight schedules and need to maintain a steady supply of packaging.

Trends and Innovations

The metal tin box industry is not without its challenges, including competition from plastic packaging and fluctuating raw material prices. However, suppliers are continuously evolving to meet market demands. Innovations such as the introduction of easy-open lids, stackable designs, and printed inner linings enhance user experience and keep products fresh.

Moreover, suppliers are becoming more adept at incorporating technology into their operations. For instance, some use advanced printing techniques that allow for intricate designs on metal surfaces, making their products even more attractive.

Conclusion

As businesses and consumers alike pivot towards sustainable practices, the role of metal tin box suppliers will only become more significant. These suppliers are not just providers of packaging; they are partners in creating brand identity and ensuring product safety. By focusing on quality, customization, and eco-friendliness, metal tin box suppliers are positioning themselves at the forefront of a packaging revolution that prioritizes both functionality and aesthetics. As we move into the future, the demand for these versatile containers is likely to increase, highlighting the critical role of their suppliers in the global market.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025