Jan . 09, 2025 12:15 Back to list

printed tinplate sheet

The printed tinplate sheet has emerged as an essential component within various industries, underpinning countless products with its unique blend of durability and aesthetic appeal. These sheets are a form of tinplate, comprised mainly of a thin steel sheet coated with a layer of tin, which is then printed upon to convey a vibrant, protective finish suitable for a multitude of applications.

Trustworthiness is further reinforced through transparent supply chains and ethical sourcing of raw materials. Reputable manufacturers prioritize eco-friendly practices, such as recycling tinplate scrap and minimizing waste during production. Partnerships with sustainable metal suppliers guarantee that the raw materials used are responsibly obtained, aligning with the growing consumer demand for environmentally conscious products. These efforts not only build confidence among buyers but also contribute to a larger movement towards sustainability within the industry. The printed tinplate sheet represents more than just a packaging solution; it embodies a culmination of technology, artistry, and reliability. Its application spans far beyond food and beverages, reaching into cosmetics, pharmaceuticals, and decorative goods, each benefiting from tinplate's unmatched combination of protection and presentation. Businesses leveraging printed tinplate sheets gain a competitive edge, enjoying both the functional benefits and the opportunity to make a striking impression in an ever-competitive marketplace. In summary, the printed tinplate sheet exemplifies the intersection of experience, expertise, authority, and trust. It is a testament to how traditional materials, when combined with modern technology and sustainability efforts, can evolve to meet contemporary needs while preserving their foundational strengths. Businesses and consumers alike can rely on these sheets for products that are as durable as they are delightful.

Trustworthiness is further reinforced through transparent supply chains and ethical sourcing of raw materials. Reputable manufacturers prioritize eco-friendly practices, such as recycling tinplate scrap and minimizing waste during production. Partnerships with sustainable metal suppliers guarantee that the raw materials used are responsibly obtained, aligning with the growing consumer demand for environmentally conscious products. These efforts not only build confidence among buyers but also contribute to a larger movement towards sustainability within the industry. The printed tinplate sheet represents more than just a packaging solution; it embodies a culmination of technology, artistry, and reliability. Its application spans far beyond food and beverages, reaching into cosmetics, pharmaceuticals, and decorative goods, each benefiting from tinplate's unmatched combination of protection and presentation. Businesses leveraging printed tinplate sheets gain a competitive edge, enjoying both the functional benefits and the opportunity to make a striking impression in an ever-competitive marketplace. In summary, the printed tinplate sheet exemplifies the intersection of experience, expertise, authority, and trust. It is a testament to how traditional materials, when combined with modern technology and sustainability efforts, can evolve to meet contemporary needs while preserving their foundational strengths. Businesses and consumers alike can rely on these sheets for products that are as durable as they are delightful.

Latest news

-

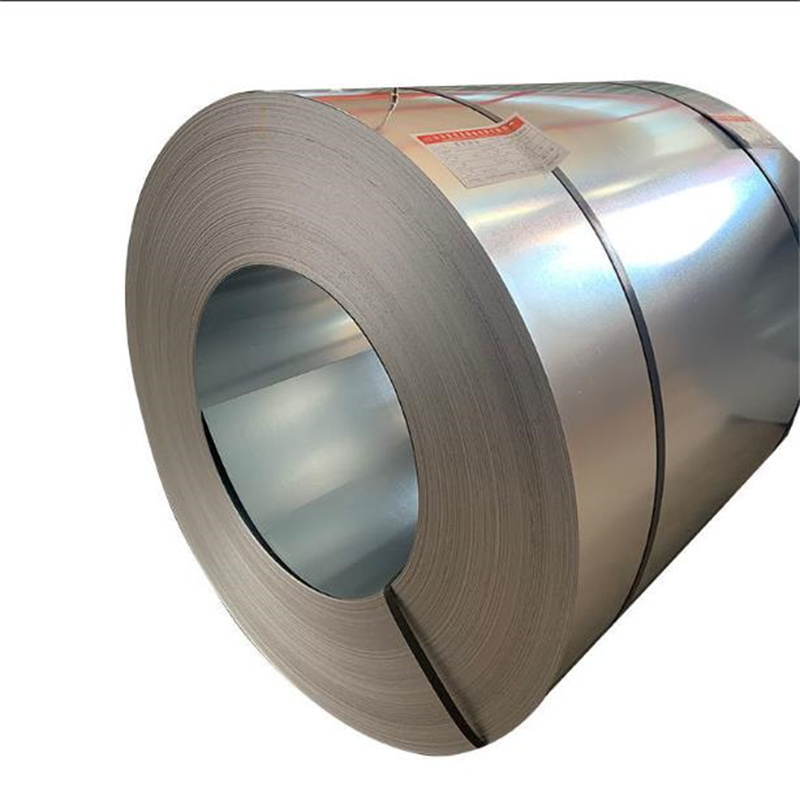

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025