Nov . 26, 2024 01:02 Back to list

mints in tin can manufacturer

The Role of Mint Production in Tin Can Manufacturing

In today’s fast-paced world, where convenience often trumps traditional practices, the mint sector has found a unique niche in the realm of tin can manufacturing. Mint, known for its refreshing aroma and flavor, is not only a beloved ingredient in culinary practices but also plays a significant role in various industries, including food and beverage, cosmetics, and pharmaceuticals. This article explores the relationship between mint production and the tin can manufacturing process, shedding light on the benefits, market trends, and environmental considerations.

The Growing Demand for Mint

Mint, specifically spearmint and peppermint, has seen an increased demand in recent years. This surge can be attributed to its multifaceted uses. In the food industry, mint is a popular flavoring agent in beverages, candies, and sauces. Moreover, it is widely used in the production of essential oils for aromatherapy and personal care products. As the health-conscious population grows, the demand for natural ingredients like mint continues to rise.

This growing market for mint has created a symbiotic relationship with the tin can manufacturing sector. Tin cans are a popular choice for packaging because they are durable, lightweight, and offer excellent protection against environmental factors. This makes them an ideal choice for packaging mint-based products such as mint-flavored beverages, chewing gums, and even mint-infused oils.

The Manufacturing Process

The process of turning raw mint into a market-ready product involves several steps, and tin can manufacturing plays a crucial role in this supply chain. After harvesting, mint is typically dried and processed into an extract or oil. Once the product is ready, appropriate packaging is essential to maintain freshness and quality.

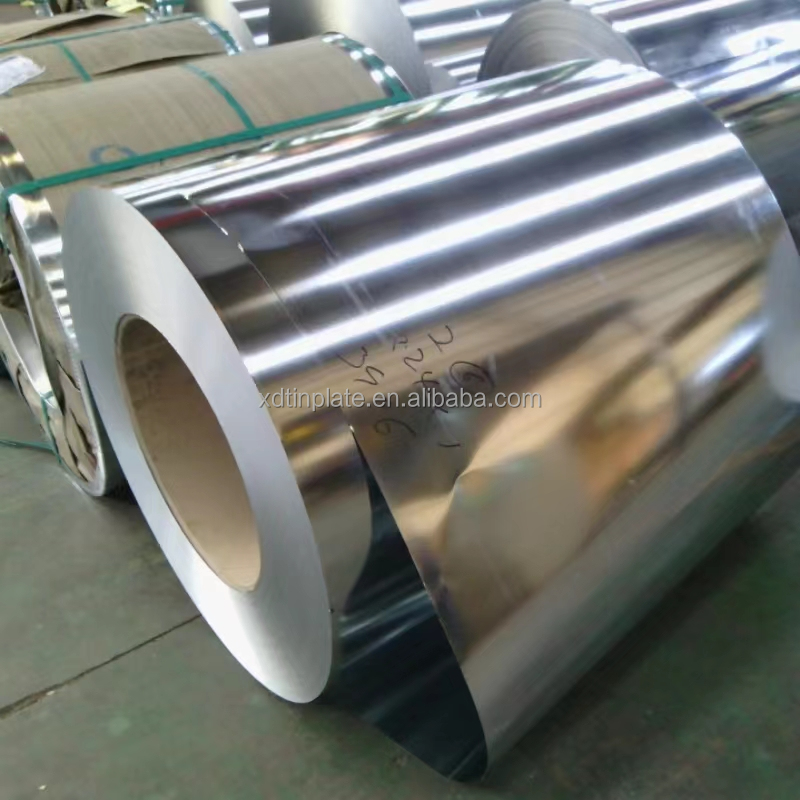

Tin can manufacturing involves several stages the creation of the can body, the application of coatings to prevent corrosion, and the sealing of the can to ensure the product's shelf life. The choice of tin for packaging is due to its non-reactive properties, which helps preserve the integrity of mint-based products. This type of packaging also appeals to consumers who are becoming increasingly mindful of sustainability and product safety.

mints in tin can manufacturer

Environmental Impact and Sustainability

As industries evolve, so does the need for sustainable practices. The tin can manufacturing process has made strides in reducing its environmental footprint. Many manufacturers are now turning to recycled tin and implementing more efficient production methods. Additionally, the recyclability of tin cans makes them a preferred packaging option for eco-conscious consumers.

Mint cultivation, too, is adapting to sustainable practices. Farmers are increasingly using organic methods to grow mint, avoiding synthetic pesticides and fertilizers. Additionally, integrated pest management techniques are employed to sustain the health of mint crops while minimizing environmental impact. This commitment to sustainability not only benefits the planet but also appeals to consumers who are increasingly investing in ethically sourced products.

Market Trends and Future Prospects

The future looks promising for both the mint and tin can manufacturing industries. Market research indicates a steady growth in the demand for mint-infused products across different sectors. This trend is further boosted by the rise of health and wellness products, as consumers are seeking natural and organic ingredients.

Moreover, the food and beverage industry continues to innovate with new mint-based products, driving the need for effective and sustainable packaging solutions. The reliability and efficiency of tin cans in preserving flavor and freshness position them well within this growing market.

Conclusion

The intersection of mint production and tin can manufacturing reflects the broader trends of modern consumerism and environmental awareness. As demand for mint and mint-infused products grows, the tin can sector is poised to thrive alongside it. By embracing sustainable practices and responding to consumer preferences, both industries can ensure a fruitful future. The journey from mint cultivation to tin can manufacturing is not only a testament to innovation but also a commitment to quality and sustainability, principles that will continue to shape the market in the years to come.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025