Dec . 15, 2024 16:09 Back to list

Cost of Metal Roofing Sheets from Various Manufacturers

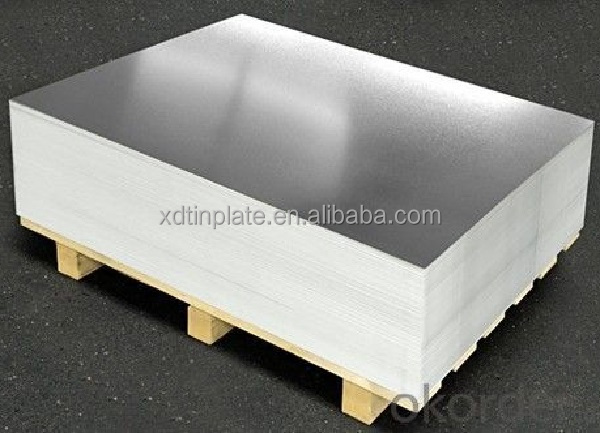

Understanding Metal Sheet Prices for Roofing A Deep Dive

In recent years, the construction industry has witnessed a growing trend towards using metal sheets for roofing. These materials offer durability, weather resistance, and aesthetic appeal. However, as with any building material, the pricing of metal sheets can vary significantly based on various factors. This article aims to explore what influences the prices of metal sheets for roofing and how homeowners and contractors can make informed decisions.

Types of Metal Roofing

Metal roofing comes in several types, the most common being steel, aluminum, copper, and zinc. Each material comes with its own set of characteristics and costs

1. Steel Often galvanized or coated, steel is one of the most popular choices for metal roofing due to its strength and affordability. Prices for galvanized steel sheets can range from $1 to $3 per square foot, depending on the thickness and quality.

2. Aluminum Known for its lightweight and corrosion-resistant properties, aluminum roofing is generally more expensive, with costs running from $2 to $5 per square foot. This type is ideal for coastal areas due to its resistance to saltwater corrosion.

3. Copper As a premium roofing material, copper offers exceptional longevity and an unmatched aesthetic. However, it is also one of the most expensive options, with prices often reaching $10 per square foot or more.

4. Zinc Zinc roofing is known for its unique looks and long lifespan. Pricing is generally in the range of $2 to $5 per square foot, but installation can be more complicated, which may drive up overall costs.

Factors Influencing Prices

metal sheet for roof price factories

Several other factors contribute to the pricing structure of metal sheets for roofing. Understanding these can help consumers budget effectively

1. Thickness and Gauge Thicker sheets are generally more durable and therefore more expensive. Metal sheets are available in various gauges, with lower numbers indicating thicker sheets. For example, a 24-gauge steel sheet may cost more than a 26-gauge sheet.

2. Coatings and Finishes Protective coatings, like paint or Galvalume, can enhance longevity and appearance but come at an additional cost. These finishes not only improve aesthetic appeal but also increase resistance to rust and sun damage.

3. Market Demand and Supply Prices can fluctuate based on the overall metal market, influenced by global supply chains, tariffs, and demand for construction. Keeping an eye on market trends can help buyers make timely purchases.

4. Manufacturing Location Where the metal sheets are sourced from can significantly affect the price. Imported sheets may come with additional shipping costs or tariffs, making them pricier than those sourced locally.

5. Installation Costs Even the best-quality metal sheets can become a drain on finances if installation costs are not factored in. Hiring qualified professionals for installation will ensure that your roofing lasts and performs as intended, but labor costs can vary widely based on location and contractor experience.

Conclusion

As the demand for innovative and long-lasting roofing materials grows, understanding the pricing dynamics of metal sheets becomes crucial for homeowners and contractors alike. By considering materials, thickness, coatings, and market factors, consumers can make informed choices that align their budget with their roofing needs.

Whether you choose steel, aluminum, copper, or zinc, investing in metal roofing can provide substantial returns in terms of durability and energy efficiency. With proper research and budgeting, you can secure the best prices and ensure a roof that not only protects but also enhances the value of your property.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025