Sep . 29, 2024 04:58 Back to list

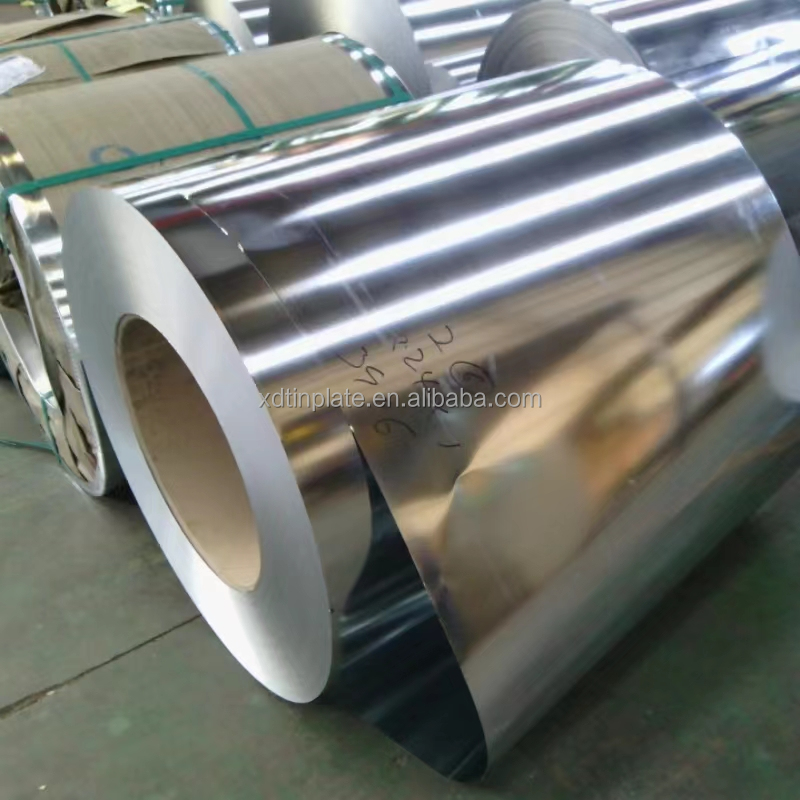

Leading Manufacturer of Galvanized Roofing Sheets for Durable Construction Solutions

The Role of Galvanized Roof Sheet Manufacturers in Modern Construction

The construction industry continually evolves, adopting innovative materials to enhance building durability, aesthetics, and sustainability. Among these materials, galvanized roof sheets stand out due to their remarkable properties and wide-ranging applications. Manufacturers specializing in galvanized roof sheets play a crucial role in this sector, delivering high-quality products that significantly contribute to modern building practices.

Understanding Galvanized Roof Sheets

Galvanized roof sheets are metal sheets that have been coated with a layer of zinc to prevent corrosion. This process, known as galvanization, involves immersing steel or iron sheets in molten zinc, creating a protective barrier. The result is a material that combines the strength of steel with the corrosion resistance of zinc, making it an ideal choice for roofing in various climatic conditions.

One of the key benefits of galvanized roof sheets is their longevity. These sheets can withstand harsh weather conditions, including heavy rain, snow, and intense sunlight, without compromising their structural integrity. Additionally, the zinc coating provides an additional layer of protection against rust and corrosion, significantly extending the lifespan of the roofing material.

The Importance of Quality in Manufacturing

The quality of galvanized roof sheets is paramount, as it directly impacts the performance and durability of the roofs they cover. Manufacturers are tasked with adhering to stringent standards during the production process. Quality control measures ensure that the sheets meet specific thickness, coating weight, and strength requirements. Reputable manufacturers engage in rigorous testing and compliance checks, guaranteeing that their products can withstand the rigors of their intended applications.

Advanced manufacturing techniques and technologies play a significant role in producing high-quality galvanized roof sheets. Innovative machinery and automated processes allow for precise cutting, shaping, and coating of the sheets, minimizing defects and ensuring consistency. Manufacturers also invest in research and development to stay ahead of industry trends, adopting new materials and methods that improve the performance of their products.

galvanized roof sheet manufacturer

Sustainability and Environmental Considerations

In today’s environmentally conscious market, galvanized roof sheet manufacturers are increasingly focusing on sustainable practices. The use of zinc is an essential aspect of this commitment, as zinc is a naturally occurring and recyclable material. Many manufacturers are exploring ways to minimize waste during the production process and reduce their carbon footprint. This includes optimizing energy use and finding alternative sources for raw materials.

Furthermore, galvanized roof sheets contribute to energy efficiency in buildings. Their reflective surface helps keep interiors cooler, reducing the need for air conditioning and lowering energy costs. This energy efficiency aligns with modern construction practices that prioritize sustainability and environmental responsibility.

Diverse Applications

Galvanized roof sheets have diverse applications across various sectors, including residential, commercial, and industrial construction. In residential settings, they are commonly used for homes, garages, and sheds. Their lightweight nature and ease of installation make them a preferred choice for builders and homeowners alike.

In commercial and industrial applications, galvanized roof sheets are favored for warehouses, factories, and agricultural buildings. Their durability and ability to withstand heavy loads and extreme weather conditions make them suitable for such environments. Additionally, the aesthetic appeal of galvanized roof sheets, combined with their availability in various colors and finishes, allows architects and builders to create visually appealing structures.

Conclusion

Galvanized roof sheet manufacturers are vital players in the construction industry, providing indispensable materials that enhance the durability, aesthetics, and sustainability of buildings. As the demand for high-quality roofing solutions continues to grow, these manufacturers must innovate and adapt to changing market needs while maintaining strict quality standards. Their commitment to producing reliable and environmentally friendly products will undoubtedly contribute to the advancement of sustainable construction practices and the overall enhancement of the built environment. In an ever-evolving industry, galvanized roof sheets will remain a prominent and essential choice for developers, builders, and homeowners alike.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025