Dec . 04, 2024 15:35 Back to list

Galvanized Iron Texture Production and Supply from Leading Manufacturers Worldwide

Understanding Galvanized Iron Texture Manufacturers

Galvanized iron has become a staple in various industries due to its remarkable resistance to corrosion and rust, making it a preferred choice for construction, manufacturing, and many other applications. The process of galvanization involves coating iron or steel with a layer of zinc to enhance its durability and longevity. Manufacturers of galvanized iron textures play a crucial role in producing materials that are both functional and aesthetically appealing.

The Process of Manufacturing Galvanized Iron

The galvanization process typically involves several key steps. First, the base metal, usually iron or steel, is cleaned thoroughly to remove any contaminants such as dirt, oil, or rust. This step is essential to ensure that the zinc coating adheres properly to the surface. The cleaning process can involve methods such as pickling, in which acids are used to strip away impurities.

Once cleaned, the metal is either hot-dipped or electro-galvanized. In hot-dipping, the metal is submerged in molten zinc, forming a strong bond with the surface. This results in a thicker layer of zinc and typically offers better protection against corrosion. Electro-galvanization, on the other hand, uses an electric current to deposit a thin layer of zinc onto the metal’s surface. While this method yields a smoother finish, it may not provide the same level of corrosion resistance as hot-dipped galvanized products.

Importance of Textures

Texture is becoming an increasingly important aspect in the design and functionality of galvanized iron products. Manufacturers now offer a variety of textures that not only enhance the aesthetic appeal but also improve the material's performance. Textured surfaces can provide better grip, reduce glare, and increase surface area, which can enhance the adhesion of paints or other coatings.

For instance, manufacturers might produce galvanized iron sheets with patterns such as embossed, patterned, or brushed textures. These variations can cater to different market needs, from decorative applications in architecture to functional uses in industrial settings. The textured surfaces not only serve visual purposes but can also help in dissipating heat, reducing friction, and even improving the mechanical properties of the material.

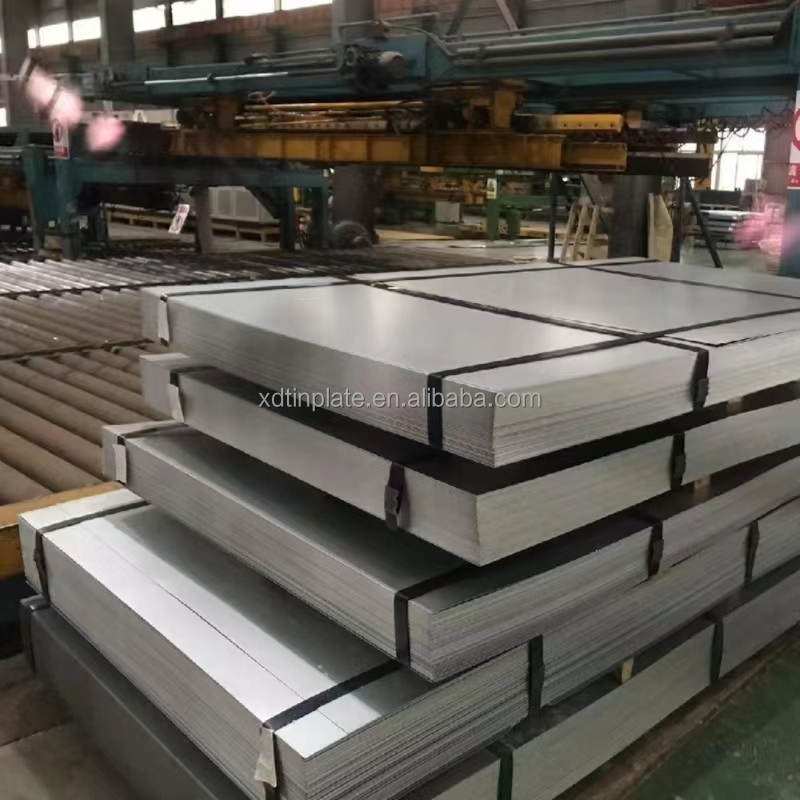

galvanized iron texture manufacturers

Environmental Considerations

As with many manufacturing processes today, the environmental impact of galvanized iron production is worth considering. Manufacturers are increasingly adopting sustainable practices to reduce waste and emissions. This includes recycling zinc from unused materials and optimizing energy use during the galvanization process. By producing galvanized iron products responsibly, manufacturers can meet the growing demand for eco-friendly building materials without compromising on quality.

Market Demand for Galvanized Iron Textures

The demand for galvanized iron textures continues to grow across various sectors. Construction companies are increasingly using galvanized iron for roofing sheets, siding, and structural components due to its durability and low maintenance requirements. Additionally, industries such as agriculture, automotive, and electronics recognize the benefits of galvanized iron in their applications.

Manufacturers are continuously innovating to meet this demand. With advancements in technology, they can offer enhanced textures that not only meet functional needs but also provide unique design elements to attract consumers. The versatility of galvanized iron, coupled with innovative texturing techniques, positions manufacturers to play a crucial role in the evolving marketplace.

Conclusion

In conclusion, galvanized iron texture manufacturers are at the forefront of blending functionality with aesthetics in the production of galvanized iron products. As industries continue to recognize the benefits of these materials, the importance of texture, sustainability, and innovation becomes paramount. The future of galvanized iron appears promising, driven by a commitment to quality, environmental responsibility, and the ever-evolving needs of the market.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025