Nov . 05, 2024 05:55 Back to list

galvanized iron remnant manufacturer

The Rise of Galvanized Iron Remnants A Manufacturer’s Perspective

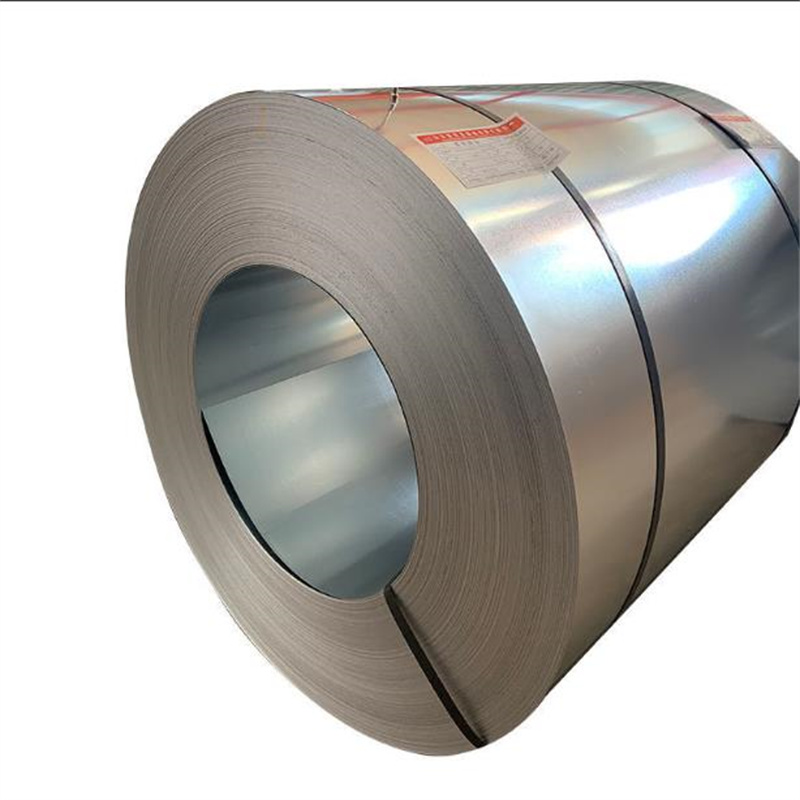

Galvanized iron, a material known for its corrosion resistance and durability, has become a staple in various industries including construction, automotive, and infrastructure development. As sustainability gains traction globally, galvanized iron remnants are emerging as an important focus for manufacturers. This shift not only represents an opportunity for economic growth but also aligns with environmental objectives.

Understanding Galvanized Iron

Galvanized iron is created by coating iron or steel with a layer of zinc to prevent rusting. The process involves hot-dipping or electroplating the metal, resulting in a protective barrier that extends the lifespan of iron products. This method not only enhances durability but also ensures that products require less maintenance over time, making it an economical choice for manufacturers and consumers alike.

The Role of Remnants in Manufacturing

In the manufacturing sector, remnants refer to leftover pieces of materials after the primary production processes are complete. These remnants often include offcuts, scraps, and defective items that, instead of being discarded, can be repurposed or sold as secondary products. The importance of managing these remnants effectively cannot be overstated, especially in the case of galvanized iron, which is both a valuable resource and a significant environmental concern.

Economic Benefits of Utilizing Remnants

Manufacturers that focus on galvanized iron remnants can benefit economically in several ways. By recycling and reusing these materials, they can reduce waste and cut down on production costs. The recycling of galvanized iron not only conserves the energy and resources that would otherwise be used to create new materials but also opens up new revenue streams through the sale of remnants. This approach fosters a circular economy where materials are kept in use for as long as possible, ultimately benefiting the manufacturer and the environment.

galvanized iron remnant manufacturer

Sustainability in Manufacturing Operations

The sustainable use of galvanized iron remnants aligns with global efforts to reduce carbon footprints and promote responsible manufacturing practices. By adopting strategies that prioritize the recycling and repurposing of scrap materials, manufacturers can contribute to a more sustainable future. This practice not only enhances their brand’s image as an eco-friendly entity but also appeals to a growing demographic of environmentally conscious consumers.

Market Demand for Remnants

The market demand for galvanized iron remnants is on the rise. As industries become increasingly focused on sustainability, companies are looking for ways to source materials that minimize waste and environmental impact. Manufacturers can tap into this trend by offering remnants for sale, catering to customers who are interested in lower-cost and sustainable material options. This demand not only supports manufacturers’ profitability but also promotes responsible consumption within the industry.

Challenges and Solutions

While the utilization of galvanized iron remnants presents significant advantages, it also comes with challenges. One primary concern is the quality control of remnants. Manufacturers must ensure that the remnants meet industry standards for safety and reliability. Implementing strict quality assessment protocols can help address this issue. Additionally, creating partnerships with recycling companies can streamline the process of collecting and repurposing scrap materials.

Conclusion

In conclusion, galvanized iron remnants represent a significant opportunity for manufacturers to enhance their operations, improve sustainability efforts, and contribute to a circular economy. By harnessing the economic and environmental benefits of these materials, manufacturers not only position themselves as leaders in their industry but also play a crucial role in promoting a more sustainable future. As the demand for responsible manufacturing practices continues to grow, those who embrace the potential of galvanized iron remnants will undoubtedly thrive in the evolving market landscape.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025