Aug . 29, 2024 09:33 Back to list

High-Quality Galvanized Steel Angle Iron Manufacturer

Galvanized Steel Angle Iron Manufacturer Meeting Diverse Construction Needs

In the world of construction and structural engineering, the importance of using robust and reliable materials cannot be overstated. One such material that has earned its reputation for durability and versatility is galvanized steel angle iron. Manufacturers specializing in this product play a crucial role in ensuring that various industries can source high-quality materials tailored to their specific needs.

Galvanized steel angle iron is a type of steel that has undergone galvanization—a process in which the steel is coated with a layer of zinc to protect it from corrosion. This added protection makes it ideal for applications in environments that are exposed to moisture or harsh weather conditions. Common uses of galvanized steel angle iron include structural frameworks, brackets, and supports for a wide range of projects, from residential to industrial constructions.

Choosing a reputable galvanized steel angle iron manufacturer is essential for builders and engineers looking to ensure the integrity and longevity of their projects. A quality manufacturer not only offers a range of sizes and dimensions but also adheres to stringent manufacturing standards. This ensures consistency in the product’s quality, enabling clients to achieve the precise specifications they require for their constructions.

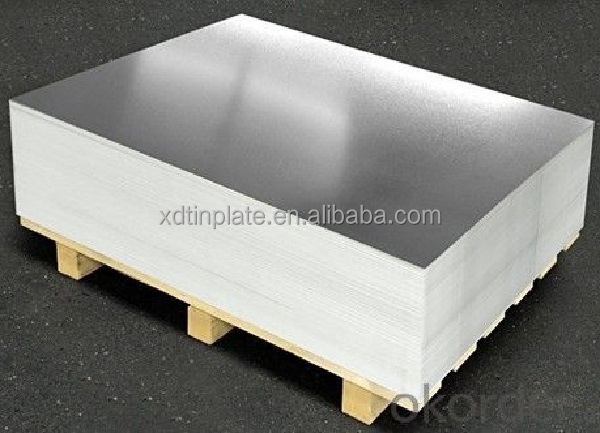

galvanized steel angle iron manufacturer

Moreover, a reliable manufacturer understands the importance of sustainability and adopts eco-friendly practices. Many modern manufacturers utilize recycled materials in their production processes, decreasing the environmental impact associated with steel production. This approach aligns with growing industry demands for sustainable construction materials, making galvanized steel angle iron an attractive option for environmentally-conscious projects.

In addition to supplying high-quality products, many galvanized steel angle iron manufacturers also offer customization services. They recognize that different projects require unique solutions, and therefore, they work closely with clients to provide tailored products that meet specific construction demands. This collaborative approach enhances customer satisfaction, ensuring that builders are equipped with the right materials for their needs.

Finally, as the market for galvanized steel angle iron continues to evolve, manufacturers are integrating advanced technologies into their operations. Innovations such as automated production lines and sophisticated quality control systems are becoming more prevalent. These advancements not only streamline the manufacturing process but also improve the overall quality of the finished products, resulting in fewer defects and greater reliability.

In conclusion, galvanized steel angle iron manufacturers play a vital role in supplying the construction industry with durable, corrosion-resistant materials. By prioritizing quality, sustainability, and customization, these manufacturers help meet the diverse needs of various projects, ensuring that construction professionals can rely on their materials for years to come. As demand for robust construction materials continues to grow, the role of these manufacturers will only become more critical in shaping the future of the industry.

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025

-

EV Car for Eco-Friendly Driving | Mini EV & New Energy Vehicles

NewsJul.28,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Green Future

NewsJul.27,2025

-

Chery Wujie Pro: Advanced Electric Vehicle for Modern Mobility

NewsJul.26,2025

-

Cost-Effective Tram: Small, Cute, and Efficient EV Car for Urban Travel

NewsJul.25,2025

-

BYD Electric Cars: Innovative New Energy Vehicles & EVs

NewsJul.24,2025