Aug . 28, 2024 15:16 Back to list

galvanised iron galvanized steel manufacturer

Understanding Galvanized Iron and Galvanized Steel The Role of Manufacturers

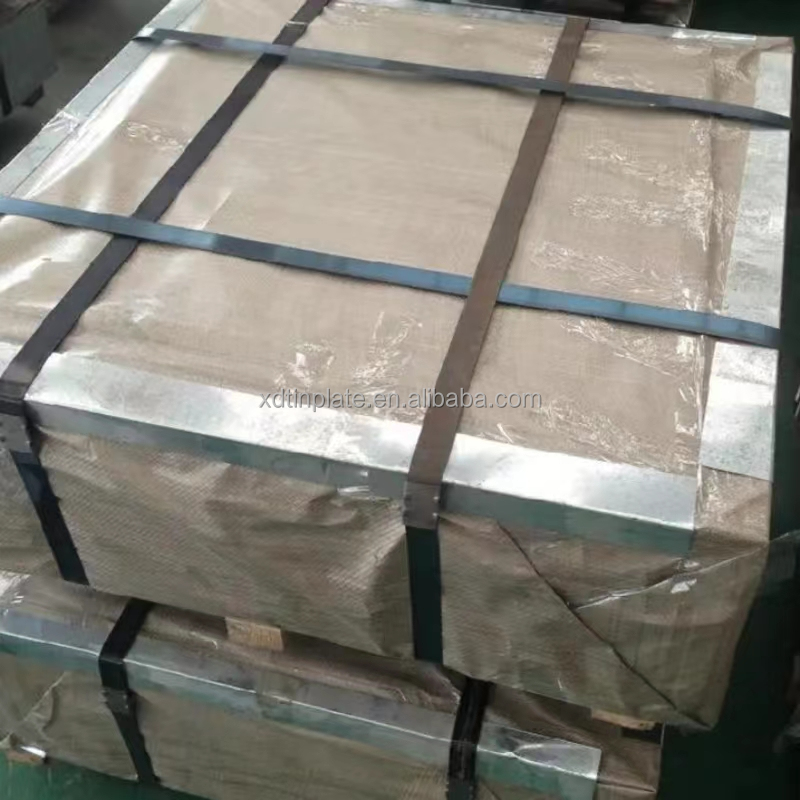

Galvanized iron and galvanized steel have become essential materials in various industries due to their enhanced durability and resistance to corrosion. Manufacturers specializing in these products play a significant role in ensuring that clients receive high-quality materials for construction, manufacturing, and repair applications.

What is Galvanization?

Galvanization is a process that involves coating iron or steel with a layer of zinc to protect it from rust and corrosion. This reaction occurs when the zinc reacts with moisture and oxygen in the environment, forming a protective barrier over the underlying metal. The galvanization process not only prolongs the life of metal products but also minimizes maintenance costs and the frequency of replacements.

Types of Galvanized Products

1. Galvanized Iron Traditionally, galvanized iron refers to iron that has been coated with zinc. It is commonly used in applications where ductility and strength are required, such as pipes, sheets, and wire. Galvanized iron can be found in several industries, including construction and agriculture.

2. Galvanized Steel This is a broader category encompassing various steel products coated with zinc. Galvanized steel is widely used in the construction of buildings, bridges, and other infrastructure due to its strength and ability to withstand extreme weather conditions. It is also favored in automotive and appliance manufacturing.

The Role of Manufacturers

Galvanized iron and steel manufacturers are key players in ensuring a reliable supply of these materials. They employ various galvanization techniques, such as hot-dip galvanizing, electro-galvanizing, and sherardizing, each with unique advantages depending on the application.

galvanised iron galvanized steel manufacturer

- Hot-Dip Galvanizing This method involves immersing steel in molten zinc, providing a thick protective layer ideal for heavy-duty applications.

- Electro-Galvanizing In this process, electrical current is used to deposit a thin layer of zinc on the steel surface, suitable for products that require a smoother finish.

- Sherardizing This technique involves heating zinc dust in a closed vessel and allows for a more uniform coating, often used for smaller components.

Manufacturers not only produce these galvanized products but often customize them to meet specific customer needs, ensuring they adhere to the required industry standards. Quality control is vital in the manufacturing process to ensure the end products perform well in their intended applications.

Environmental Considerations

In recent years, galvanized iron and steel manufacturers have also begun to focus on sustainable practices. The galvanization process can be energy-intensive, so many manufacturers are exploring ways to improve efficiency and reduce environmental impact. By implementing recycling programs for zinc and utilizing advanced technologies, the industry is moving towards more eco-friendly practices.

Conclusion

In summary, galvanized iron and galvanized steel are indispensable materials in modern construction and manufacturing. The manufacturers of these products are not only vital for delivering reliable and durable options but are also increasingly aligning with sustainability practices. As industries continue to evolve, the importance of quality galvanized materials and responsible manufacturing will only grow.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025