Aug . 01, 2024 03:41 Back to list

Exploring the Production Process of Galvanized and Black Iron in Modern Factories

Galvanized and Black Iron A Comprehensive Look at Manufacturing and Applications

In the world of metal manufacturing, two materials frequently come up in discussions galvanized iron and black iron. Both of these metals have unique properties, applications, and production processes that make them integral to various industries. Understanding the differences between them is crucial for industries ranging from construction to automotive.

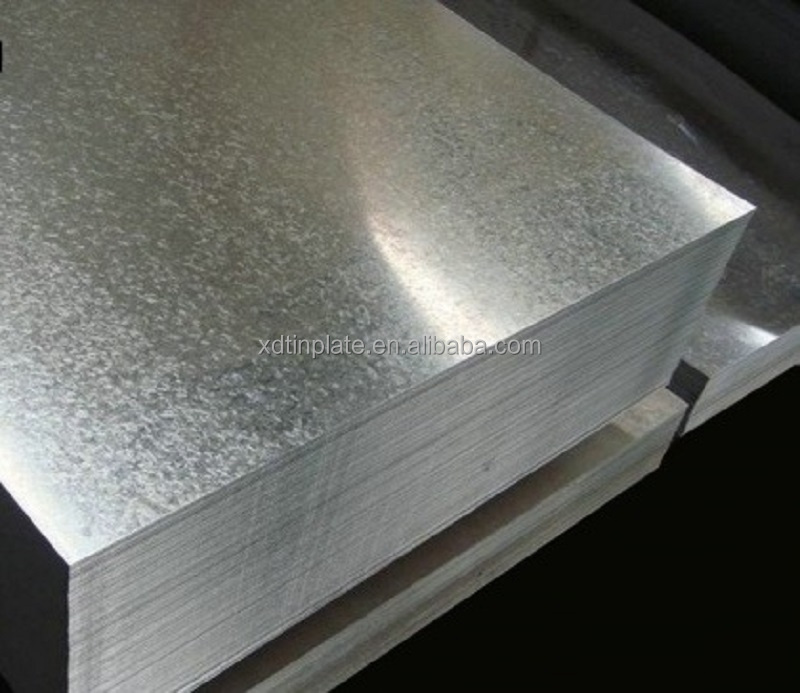

What is Galvanized Iron?

Galvanized iron is essentially iron or steel coated with a layer of zinc. This coating is applied through a process called galvanization, which is primarily done to prevent rust and corrosion. The most common method of galvanization is hot-dip galvanizing, where iron parts are submerged in molten zinc. This process not only enhances corrosion resistance but also extends the lifespan of the material, making it an ideal choice for outdoor applications.

The applications of galvanized iron are numerous. It is commonly used in the construction of buildings, fences, roofing, and even in the automotive industry for various parts. Its corrosion resistance means that it can withstand the harshest of weather conditions, making it a reliable choice for infrastructure projects. Additionally, galvanized iron is often used in agriculture for creating durable equipment and in marine applications due to its resistance to saltwater.

What is Black Iron?

Conversely, black iron refers to uncoated steel that has not been subjected to any type of protective coating. The term black refers to the iron's color, which is due to the presence of iron oxide on its surface. While black iron lacks the corrosion-resistant properties of galvanized iron, it possesses excellent strength and is ideal for applications where strength is critical.

galvanized iron black iron factory

Black iron is commonly used in the construction of pipes, structural beams, and other components where durability is needed. Although it is more susceptible to rust compared to galvanized iron, proper maintenance and painting can enhance its lifespan significantly. Black iron is often favored in plumbing systems, where it is used for water supply lines and gas pipes, due to its strength and compatibility with fittings.

Manufacturing Processes

The manufacturing processes for both types of iron involve several steps. For galvanized iron, the initial step is to create steel or iron products which are then cleaned and prepared for galvanization. The components undergo surface preparation to remove contaminants, followed by immersion in molten zinc. Once cooled, the coated products may undergo quality checks to ensure they meet industry standards.

Black iron manufacturing is more straightforward. It starts with the production of raw steel, which is then shaped into the desired form using rolling or forging processes. Sufficient care is taken to manage oxidation during production, but the final product will still have a layer of mill scale that can be removed through further processing if necessary.

Conclusion

In conclusion, both galvanized and black iron have significant roles in metal manufacturing. The choice between the two depends largely on the intended application and environmental considerations. Galvanized iron's resistance to corrosion makes it suitable for outdoor and high-moisture applications, while black iron's strength is favorable for structural components. As manufacturers continue to innovate, the use of these materials is likely to evolve, meeting the ever-changing demands of various industries. Understanding their properties, benefits, and applications ensures that industries can make informed decisions that enhance their productivity and longevity.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025