Aug . 29, 2024 11:55 Back to list

Cost of Steel Sheet Roofing - Affordable Steel Roofing Solutions

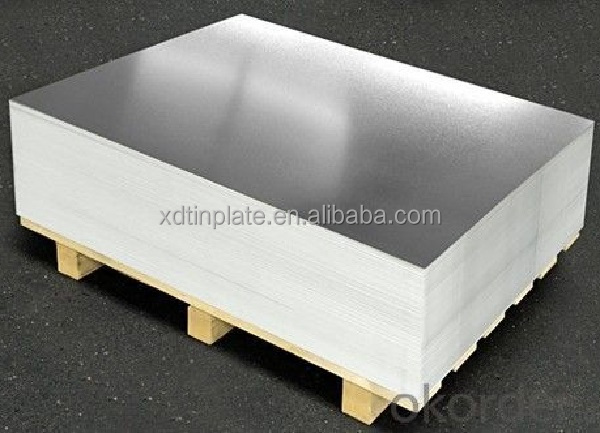

Understanding the Cost of Steel Sheets for Roof Suppliers

When it comes to roofing materials, steel sheets have gained immense popularity due to their durability, aesthetic appeal, and cost-effectiveness. However, the overall cost of steel sheets can vary significantly based on various factors, which is crucial for both suppliers and consumers to understand. This article delves into the key elements that influence the cost of steel sheets for roofing and provides insights for suppliers navigating this competitive market.

1. Material Quality and Type

The quality of steel is a primary determinant of its cost. Steel sheets are available in various grades, including galvanized, stainless, and pre-painted options. Galvanized steel, which is coated with a layer of zinc to prevent rusting, tends to be affordable and offers decent durability. In contrast, stainless steel sheets, known for their corrosion resistance and strength, are generally more expensive. Suppliers must carefully choose the type of steel they wish to stock, balancing quality with cost to meet customer demands.

2. Manufacturing Process

The method used to produce steel sheets also impacts their cost. Common production techniques include hot-rolling and cold-rolling, each possessing its own cost structure. Cold-rolled steel sheets are typically thinner and more precise, leading to higher costs but better surface finishes, while hot-rolled sheets are more economical but may require additional processing for certain applications.

cost of steel sheet for roof supplier

The thickness of the steel sheet and its dimensions also play a significant role in pricing. Thicker sheets provide greater durability and strength but come at a higher cost. Additionally, the size of the sheets can influence costs as larger sheets may be more economical due to reduced waste in cutting and handling. Suppliers need to balance these factors to cater to various projects, from residential roofing to industrial applications.

4. Market Demand and Supply Chain Dynamics

The broader economic landscape significantly affects the cost of steel sheets. During times of increased construction activity, demand for roofing materials rises, leading to potential price hikes. Additionally, global supply chain issues, such as transportation delays or raw material shortages, can cause fluctuations in prices. Suppliers must stay abreast of market trends and adjust their pricing strategies accordingly.

5. Additional Features and Accessories

Some roofing projects may require additional features such as insulation, fire resistance, or soundproofing. These added specifications will increase the overall cost of the steel sheets or necessitate the purchase of complementary materials. Suppliers should provide clear information about these options to help customers make informed decisions.

Conclusion

Navigating the cost of steel sheets for roofing requires a thorough understanding of the various factors at play, from material quality and manufacturing processes to market dynamics. For suppliers, maintaining transparency about pricing and providing diverse options can foster trust and loyalty among customers. As the demand for steel roofing continues to grow, suppliers who adapt to these factors will position themselves for success in a competitive marketplace. Ultimately, understanding and managing the cost components will not only benefit suppliers but will also lead to improved customer satisfaction.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025