Aug . 29, 2024 12:34 Back to list

corrugated steel sheet thickness factories

The Importance of Thickness in Corrugated Steel Sheet Manufacturing

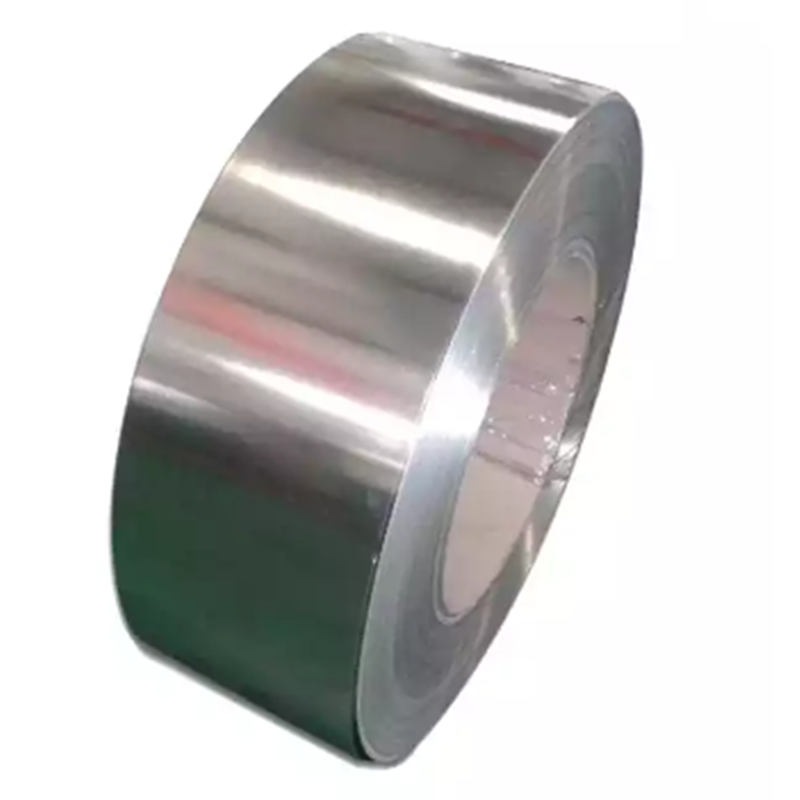

Corrugated steel sheets have become a staple in various industries, from construction to manufacturing, thanks to their durability and versatility. One of the crucial factors that influence the performance and application of these sheets is their thickness. Understanding the significance of thickness in corrugated steel sheet manufacturing is essential for both manufacturers and end-users.

What is Corrugated Steel?

Corrugated steel is a sheet metal product that has been pressed into ridges and valleys, enhancing its strength and rigidity. This unique design allows the material to withstand various environmental factors, making it ideal for roofing, siding, and other structural applications. The production process involves shaping flat sheets of steel through cold rolling or molding, resulting in multiple thickness options tailored to specific needs.

The Role of Thickness

The thickness of corrugated steel sheets is one of the primary factors affecting their structural integrity and overall performance. Generally measured in gauge or millimeters, the standard thickness ranges from 0.3 mm to 1.2 mm for most applications. Thicker sheets provide greater strength and durability, making them suitable for heavy-duty applications, such as industrial buildings or agricultural structures. On the other hand, thinner sheets may be used for less demanding environments, where lightweight materials are preferred.

corrugated steel sheet thickness factories

Impact on Durability

One of the primary reasons thickness is critical in corrugated steel sheets is its direct impact on durability. Thicker sheets are less prone to bending, warping, or denting compared to their thinner counterparts. This resilience is particularly important in regions prone to heavy winds, snowfall, or other environmental stressors. For contractors and architects, selecting the appropriate thickness can mean the difference between a structure that withstands the test of time and one that requires frequent repairs.

Cost Considerations

While thickness is crucial for performance, it is also essential to consider the cost implications. Thicker sheets tend to be more expensive due to the increased material usage and production costs. However, investing in higher thickness can lead to long-term savings by reducing maintenance and replacement needs. Thus, end-users must assess their specific project requirements and budget when choosing the thickness of corrugated steel sheets.

Conclusion

In conclusion, the thickness of corrugated steel sheets plays a pivotal role in determining their suitability for various applications. It affects the durability, strength, and cost of the material, making it a significant consideration for manufacturers and users alike. As the demand for durable and efficient construction materials continues to rise, understanding the nuances of corrugated steel sheet thickness will remain vital in the industry. By choosing the appropriate thickness, stakeholders can ensure that their projects benefit from the maximum performance and longevity of corrugated steel, thereby investing wisely in their infrastructure and future.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025