Aug . 06, 2024 11:41 Back to list

Comprehensive Overview of Flat Roof Factories and Their Capacity Sheet Metrics

Understanding the Cap Sheet and Its Role in Flat Roof Factories

In the realm of roofing systems, particularly flat roofs, cap sheets are an essential element that contributes to durability and performance. Cap sheets are used as the top layer in built-up roofing (BUR) systems, which are widely adopted in various commercial and industrial buildings. This article delves into the characteristics, advantages, and the overall significance of cap sheets in flat roof applications.

What is a Cap Sheet?

A cap sheet is a protective top layer of modified bitumen or asphalt that is applied over a flat roof system. Typically, these sheets are rolled out and adhered using methods such as torching, cold adhesive, or self-adhesive technology. Cap sheets are designed to provide superior waterproofing while also acting as a barrier against UV rays and physical wear. They come in various finishes and colors, allowing for aesthetic flexibility while ensuring functionality.

The Manufacturing Process

Flat roof factories play a critical role in producing high-quality cap sheets. The manufacturing process begins with the selection of raw materials, which include bitumen, polymers, and reinforcements like fiberglass or polyester. These materials are carefully blended to create a composite membrane that provides robustness and flexibility.

Once the composite is formed, it is rolled out and subjected to various inspections to ensure it meets industry standards. The factory process often includes quality control measures, such as testing for tensile strength, elongation, and resistance to extreme temperatures. By adhering to stringent manufacturing practices, flat roof factories ensure that cap sheets are durable and can withstand the challenges posed by weather and environmental conditions.

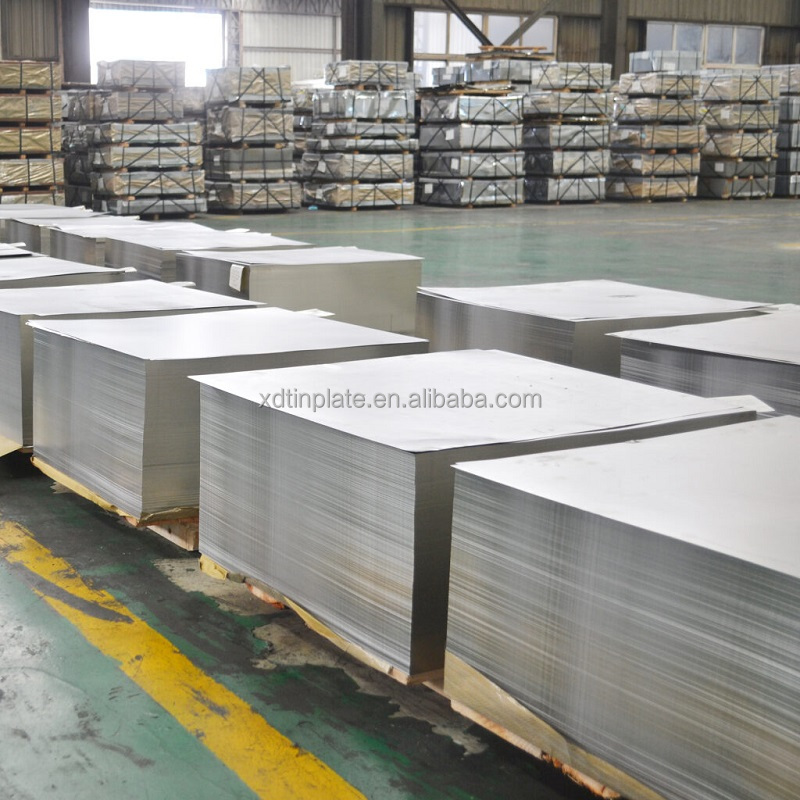

cap sheet flat roof factories

Advantages of Cap Sheets

The use of cap sheets brings numerous advantages to flat roofing systems. One of the primary benefits is waterproofing. Unlike traditional roofing materials, cap sheets create a seamless, watertight barrier that significantly reduces the risk of leaks and water damage. This feature is particularly crucial for flat roofs, which are more susceptible to ponding water, especially during heavy rain.

Moreover, cap sheets offer excellent resistance to UV rays and thermal fluctuations. This quality helps extend the life of the roofing system, as it minimizes degradation caused by exposure to sunlight and temperature changes. Additionally, most cap sheets come with a reflective coating that improves energy efficiency, helping to keep buildings cooler in the summer and reducing cooling costs.

Installation and Maintenance

The installation of cap sheets should be carried out by professionals to ensure the integrity of the roofing system. Proper application techniques are vital to achieving a secure bond and effective waterproofing. Regular maintenance checks are also essential to prolong the life of a flat roof covered with cap sheets. This includes inspecting for signs of wear, such as cracks or blisters, and performing timely repairs.

Conclusion

In summary, cap sheets play an indispensable role in the performance and longevity of flat roofing systems. Produced in specialized flat roof factories, these protective layers provide essential waterproofing and UV protection, thus enhancing the overall durability of the roof. As the demand for reliable roofing solutions continues to rise, understanding the intricacies of cap sheets and their manufacturing processes becomes increasingly important for architects, builders, and property owners alike. By prioritizing quality and proper installation, stakeholders can ensure that their flat roofs remain resilient against the elements, safeguarding their investments for years to come.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025