Feb . 10, 2025 10:34 Back to list

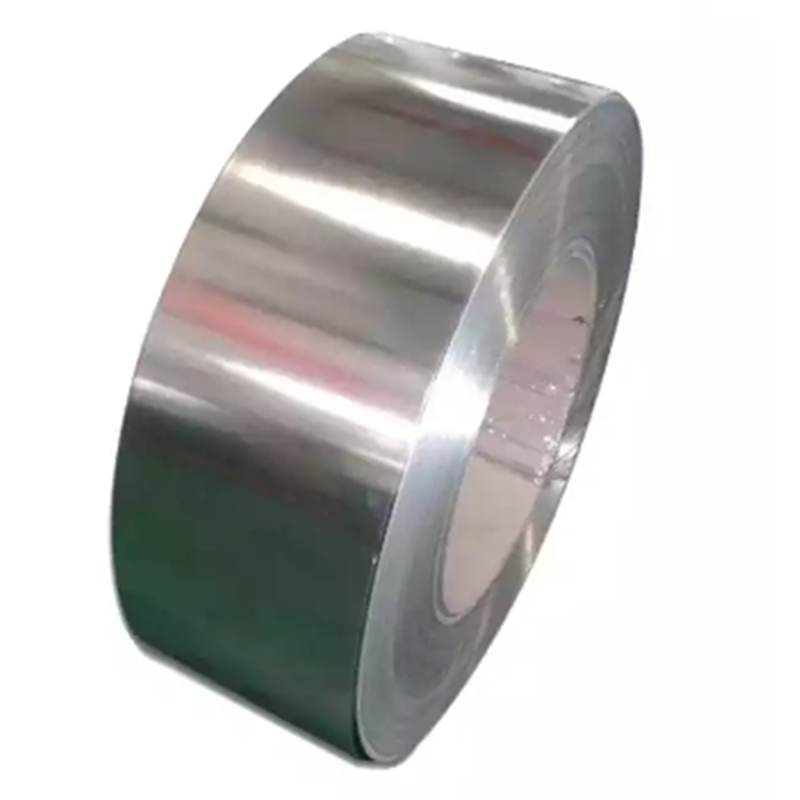

Galvanized steel sheet price hot-dip galvanized

In the realm of construction and architectural innovation, roofing plays a pivotal role in defining both the aesthetics and durability of a structure. As industries evolve, there's an increasing demand for high-quality, efficient, and sustainable roofing solutions. Among these, the use of coil metal for roofing has emerged as a front runner, offering unparalleled benefits.

The engineering behind coil metal roofing also stands testament to the expertise involved in its production. With advancements in technology, factories are leveraging state-of-the-art machinery to roll and finish coil metals with precision. This precision ensures uniform thickness and texture, crucial for maintaining the integrity and appearance of the roof. The teams behind these innovations are typically seasoned professionals, bringing years of industry knowledge to the table, thus assuring clients of the highest quality products. Furthermore, the reliability of coil metal for roofing can be seen in its widespread use in diverse environments. From residential homes and commercial establishments to industrial sites, its application is vast and varied. The trust placed in coil metal by countless developers and builders is a reflection of its performance and dependability over the years. In terms of expertise, companies engaged in the production of coil metal roofing prioritise continuous learning and adaptation. By staying abreast of the latest trends in construction technology and environmental regulations, these manufacturers ensure that they remain at the forefront of the industry. Their authoritative presence is derived from both their experience in the field and their commitment to innovation, positioning them as leaders in the market. For consumers and builders alike, choosing coil metal for roofing translates into a promise of quality, endurance, and aesthetic appeal. The benefits are multifaceted, from reduced environmental impact and cost savings to enhanced structural integrity and design freedom. As the demand for sustainable and efficient building materials continues to grow, coil metal for roofing represents a pinnacle of modern engineering and environmental stewardship.

The engineering behind coil metal roofing also stands testament to the expertise involved in its production. With advancements in technology, factories are leveraging state-of-the-art machinery to roll and finish coil metals with precision. This precision ensures uniform thickness and texture, crucial for maintaining the integrity and appearance of the roof. The teams behind these innovations are typically seasoned professionals, bringing years of industry knowledge to the table, thus assuring clients of the highest quality products. Furthermore, the reliability of coil metal for roofing can be seen in its widespread use in diverse environments. From residential homes and commercial establishments to industrial sites, its application is vast and varied. The trust placed in coil metal by countless developers and builders is a reflection of its performance and dependability over the years. In terms of expertise, companies engaged in the production of coil metal roofing prioritise continuous learning and adaptation. By staying abreast of the latest trends in construction technology and environmental regulations, these manufacturers ensure that they remain at the forefront of the industry. Their authoritative presence is derived from both their experience in the field and their commitment to innovation, positioning them as leaders in the market. For consumers and builders alike, choosing coil metal for roofing translates into a promise of quality, endurance, and aesthetic appeal. The benefits are multifaceted, from reduced environmental impact and cost savings to enhanced structural integrity and design freedom. As the demand for sustainable and efficient building materials continues to grow, coil metal for roofing represents a pinnacle of modern engineering and environmental stewardship.

Latest news

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025