Dec . 12, 2024 09:15 Back to list

china density of galvanized iron in kg/m3

Understanding the Density of Galvanized Iron An Overview

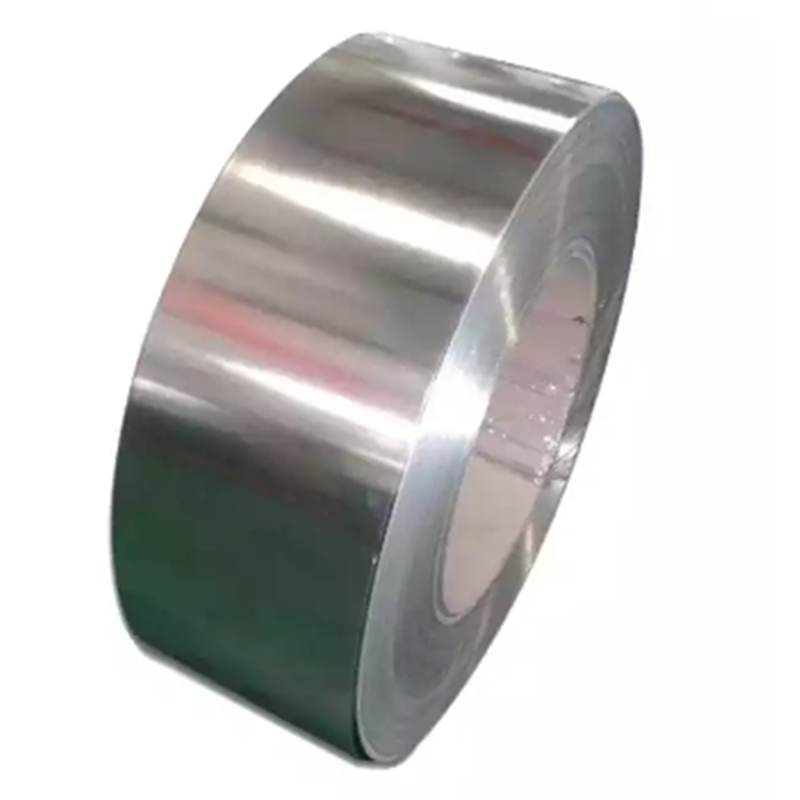

Galvanized iron, a type of steel that has been coated with zinc to prevent corrosion, is widely used in various applications, ranging from construction to automotive components. One of the key physical properties that engineers and designers consider when working with this material is its density, typically measured in kilograms per cubic meter (kg/m³). Understanding the density of galvanized iron is crucial for determining weight, structural integrity, and suitability for specific applications.

What is Density?

Density is defined as the mass of a substance per unit volume. In the case of galvanized iron, its density can be influenced by several factors, including the composition of the steel, the thickness of the zinc coating, and the manufacturing process used to create the galvanized product. Generally, the density of galvanized iron falls within the range of 7850 kg/m³ to 8050 kg/m³. This range accounts for the base iron and the additional mass contributed by the zinc coating, which typically weighs around 100 to 300 grams per square meter depending on the coating thickness.

Importance of Density in Applications

Knowing the density of galvanized iron is essential for various reasons. For instance, in construction, engineers must calculate the weight of materials to ensure the structures can support the loads applied to them. In automotive design, manufacturers consider the weight of components when optimizing fuel efficiency and overall performance. Furthermore, in industries like shipping and logistics, knowing the exact weight of galvanized iron products is vital for calculating shipping costs and space requirements.

Factors Affecting Density

china density of galvanized iron in kg/m3

Several factors can influence the density of galvanized iron. Primarily, the alloy composition of the base metal has a significant impact. Different grades of steel have varying densities depending on their alloying elements. Additionally, the thickness of the zinc layer can affect the overall density. Thicker coatings will increase the weight and density of the final product.

Another factor to consider is the production method. The hot-dip galvanizing process, which involves dipping iron or steel into molten zinc, often produces a different coating weight compared to electro-galvanizing, where zinc is applied using an electrical current. This difference in manufacturing can result in different densities for similar galvanized iron products.

Applications of Galvanized Iron

Galvanized iron is utilized in a wide variety of applications due to its corrosion resistance and mechanical strength. Common uses include roofing sheets, fences, electrical poles, and piping. In these applications, the density of the material must align with structural requirements and environmental conditions, making it imperative to use the correct specifications.

Conclusion

In conclusion, the density of galvanized iron is a critical property that influences its performance across various applications. Ranging from 7850 kg/m³ to 8050 kg/m³, understanding this material's density helps engineers and designers optimize their projects for safety, efficiency, and cost-effectiveness. As industries continue to evolve, so too will the standards and practices surrounding the use of galvanized materials, making an awareness of their properties more important than ever. Through ongoing research and development, the future of galvanized iron looks promising, contributing to sustainable and durable engineering solutions.

-

Revolutionary AI for New Energy Vehicles: GPT-4 Turbo Optimization

NewsAug.05,2025

-

Discover Cheap Cars with GPT-4 Turbo Deals | Save Big Now

NewsAug.04,2025

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025