Nov . 09, 2024 19:29 Back to list

Cast Iron Plumbing Manufacturing with Galvanized Materials for Enhanced Durability and Performance

The Significance of Cast Iron and Galvanized Plumbing in Modern Factories

In contemporary industries, reliable plumbing systems are indispensable for the smooth and efficient operation of factories. Among the various materials used in plumbing, cast iron and galvanized steel have long stood the test of time, thanks to their robustness, durability, and resistance to corrosion. This article explores the vital role of cast iron and galvanized plumbing systems in factories, highlighting their advantages, applications, and the manufacturing processes involved.

Understanding Cast Iron and Galvanized Plumbing

Cast iron plumbing has been utilized for over a century, primarily due to its strength and longevity. It is made by melting iron and pouring it into molds to create pipes and fittings. The resulting products can withstand high pressure and extreme temperatures, making them ideal for heavy-duty applications. Cast iron pipes are also known for their excellent sound-dampening qualities, significantly reducing the noise produced by flowing water.

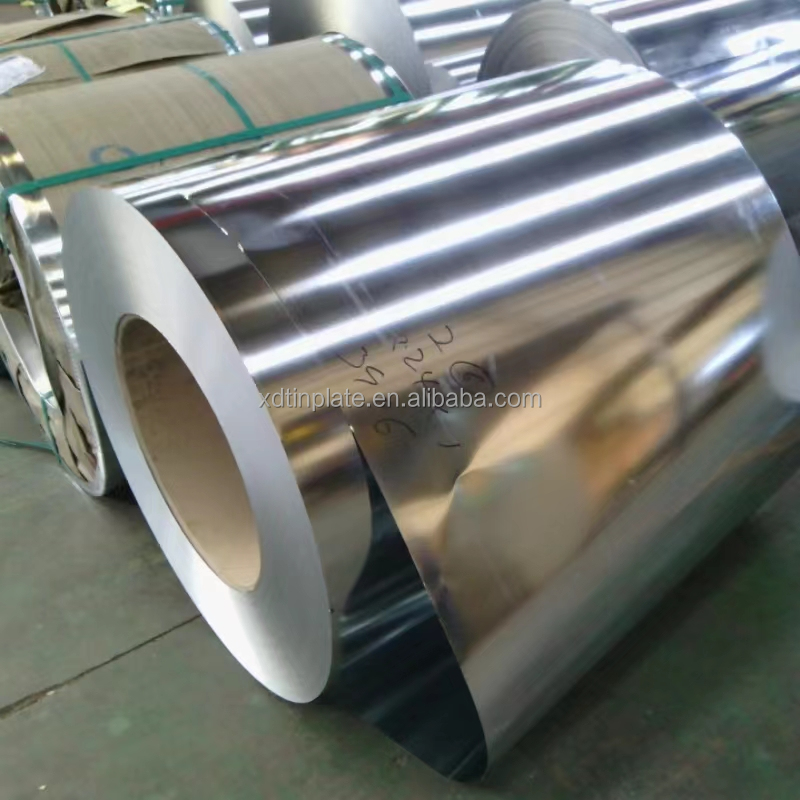

Galvanized plumbing, on the other hand, refers to steel pipes coated with a layer of zinc to prevent rust and corrosion. This zinc galvanization process involves dipping the steel in a molten zinc bath, providing a protective barrier against environmental elements. Galvanized pipes are typically lighter than cast iron, making installation easier and less labor-intensive. They are commonly used in water supply lines and drainage systems within factories.

Advantages of Cast Iron Plumbing

1. Durability and Longevity Cast iron pipes can last for over a century with minimal maintenance. Their ability to resist wear and tear makes them a preferred choice for factories where reliability is paramount.

2. Sound Insulation The dense nature of cast iron allows for superior sound absorption. This characteristic is advantageous in factories with extensive plumbing systems, reducing noise pollution in the workplace.

3. Temperature Resistance Cast iron can tolerate extreme heat and is suitable for transporting hot water and steam, making it ideal for industrial processes.

cast iron galvanized plumbing factory

Advantages of Galvanized Plumbing

1. Corrosion Resistance The zinc coating on galvanized steel provides a protective layer that prevents rust, significantly extending the life of the plumbing system.

2. Lightweight Galvanized pipes are lighter and easier to handle than cast iron, reducing labor costs and installation time in factory settings.

3. Versatility Galvanized plumbing is suitable for a variety of applications, including water supply, drainage, and even in some HVAC systems.

4. Cost-Effectiveness Generally, galvanized pipes are more affordable than cast iron, making them an attractive option for factories looking to manage costs without sacrificing quality.

Manufacturing Processes in Plumbing Factories

In plumbing factories, the production of cast iron and galvanized pipes involves sophisticated manufacturing processes. For cast iron, the production typically begins with melting scrap iron in a blast furnace. Once reached the desired temperature, it is poured into molds to create pipes and fittings. The cooling process is crucial; proper cooling ensures the integrity and strength of the final product.

On the other hand, galvanized pipes start with steel manufacturing, where a flat sheet of steel is rolled into a pipe shape and welded. This pipe is then submerged into a bath of molten zinc, which adheres to the surface, creating the necessary protective coating. The pipes are subsequently cooled and inspected for quality assurance before being dispatched for use.

Conclusion

The significance of cast iron and galvanized plumbing in factory settings cannot be overstated. Their unique properties make them suitable for various applications, ensuring the reliability and efficiency of plumbing systems. As industries continue to grow and evolve, the demand for durable, cost-effective plumbing solutions like cast iron and galvanized steel will remain essential. By understanding their benefits and manufacturing processes, factory managers and engineers can make informed decisions, ensuring that their plumbing systems are built to last. In an era where infrastructure plays a crucial role in productivity, investing in high-quality plumbing is a step toward sustainable and efficient manufacturing operations.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025