Nov . 12, 2024 02:10 Back to list

black iron galvanized pipe factory

The Importance of Black Iron and Galvanized Pipe Factories

In the ever-evolving world of construction and manufacturing, the materials used play a critical role in determining the quality, durability, and efficiency of any project. Among these materials, black iron and galvanized pipes have carved a niche for themselves due to their unique properties and diverse applications. This article delves into the significance of black iron and galvanized pipe factories, examining their production processes, applications, and contributions to the industry.

The Importance of Black Iron and Galvanized Pipe Factories

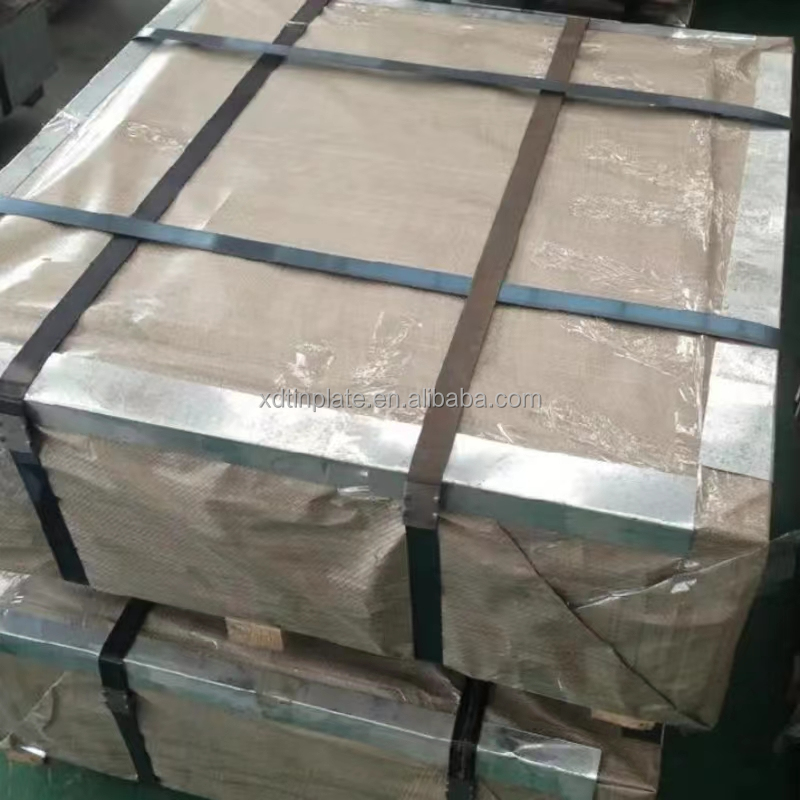

Factories dedicated to the production of black iron and galvanized pipes play a crucial role in the supply chain of various industries, including construction, plumbing, and manufacturing. The integration of advanced technology in these factories has revolutionized the pipe manufacturing process. Automated machinery, computer-controlled systems, and precision engineering allow for high-quality output while minimizing waste. Moreover, many factories emphasize sustainable practices, utilizing eco-friendly methods to reduce their carbon footprint and promote environmental stewardship.

black iron galvanized pipe factory

The versatility of black iron and galvanized pipes is a significant contributor to their demand in the market. Black iron pipes are commonly used in residential and commercial buildings for water distribution, heating systems, and gas lines. They can be easily welded, making them a preferred choice for complex piping systems. In contrast, galvanized pipes are often utilized in plumbing applications, especially in areas prone to moisture as they prevent rust and corrosion over time. They are also popular in agricultural settings for irrigation systems and in industries requiring the transport of liquids.

Quality assurance is paramount in the production of these pipes. Reputable factories adhere to strict international standards and regulations to ensure their products meet the requirements for safety and performance. Regular testing and inspection of the pipes throughout the manufacturing process help identify any defects or inconsistencies. This commitment to quality not only safeguards consumers but also enhances the factory's reputation in the industry.

Furthermore, the presence of black iron and galvanized pipe factories stimulates local economies by providing jobs and supporting related industries. From skilled laborers to engineers and supply chain specialists, these factories create a diverse range of employment opportunities. Additionally, they often collaborate with local suppliers for raw materials, fostering economic growth in the surrounding communities.

In conclusion, black iron and galvanized pipe factories are indispensable components of the construction and manufacturing landscape. Their ability to produce high-quality, durable pipes makes them essential for various applications. With continued advancements in technology and sustainable practices, these factories are poised to meet the growing demands of industries while contributing to economic growth and environmental preservation. As we progress into a future that increasingly values sustainability and efficiency, the role of these factories will undoubtedly remain critical in shaping the infrastructure of our societies.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025