Dec . 11, 2024 11:12 Back to list

4x4 galvanized angle iron factories

The Significance of 4x4 Galvanized Angle Iron in Modern Construction

In the realm of modern construction and manufacturing, the use of galvanized materials has gained significant traction due to their myriad benefits. Amongst these materials, 4x4 galvanized angle iron stands out for its versatility and durability, making it a preferred choice for various applications. This article will explore the significance of 4x4 galvanized angle iron and the factories that produce it, highlighting its advantages, manufacturing processes, and its role in the construction industry.

Understanding 4x4 Galvanized Angle Iron

4x4 galvanized angle iron is a type of structural steel that features a 90-degree angle and a cross-section shaped like an “L”. The “4x4” refers to the dimensions of the angle, specifically four inches on each leg. Galvanization involves the process of applying a protective zinc coating to steel or iron to prevent rusting and corrosion. This enhances the material’s longevity and makes it suitable for both indoor and outdoor applications.

Importance in Construction

The construction sector relies heavily on strong, durable materials that can withstand various environmental conditions. 4x4 galvanized angle iron provides excellent structural integrity, capable of bearing heavy loads and supporting various structures. It is commonly used in frames, brackets, and supports, offering stability and reliability in buildings, bridges, and other infrastructures.

One of the significant benefits of using galvanized angle iron is its corrosion resistance. In environments exposed to moisture, such as coastal areas or regions with high humidity, untreated metal is susceptible to rust and deterioration. The zinc coating on galvanized iron acts as a sacrificial anode, protecting the underlying steel from the elements. This longevity reduces maintenance costs and ensures that structures remain safe and sound over time.

The Role of Factories

Manufacturing 4x4 galvanized angle iron requires precision and technological expertise. Factories that specialize in producing angle iron must adhere to strict quality standards to ensure their products meet industry specifications. The manufacturing process typically involves several steps, including cutting, shaping, and galvanizing the angle iron.

Cutting involves slicing the steel into required lengths before they are shaped into right angles. Next, the pieces are heated and formed into the desired L-shape using advanced machinery that guarantees uniformity and strength. Once shaped, the angle iron proceeds to the galvanization process, where it is immersed in molten zinc to create a robust protective layer.

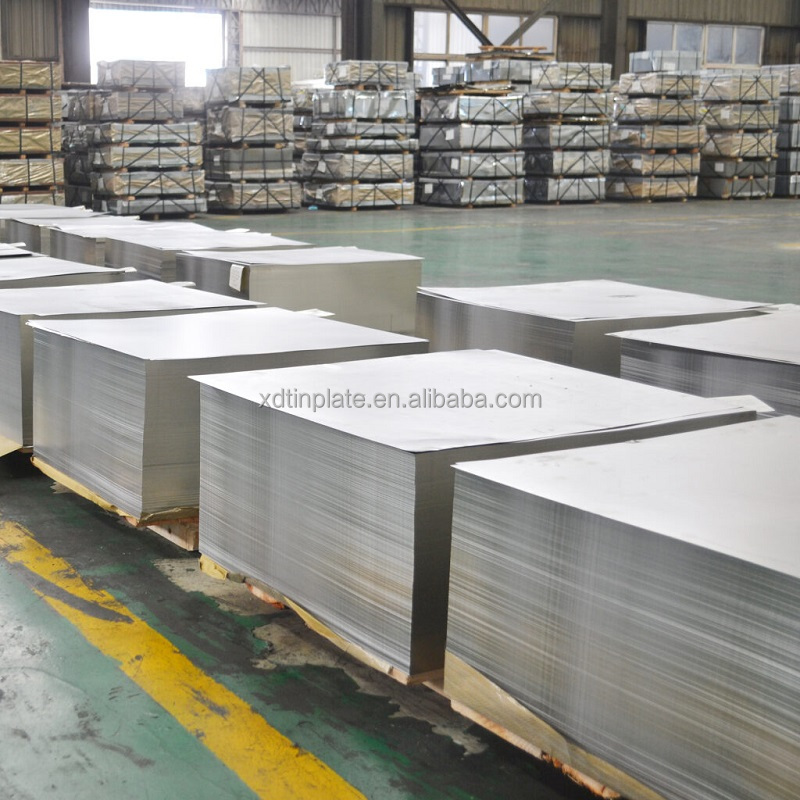

4x4 galvanized angle iron factories

Modern factories employ state-of-the-art equipment and technology, allowing for high precision and efficient production rates. Automation in manufacturing processes has drastically improved consistency and reduced labor costs, while skilled workers ensure that quality control measures are enforced throughout the production line.

Applications of 4x4 Galvanized Angle Iron

4x4 galvanized angle iron is incredibly versatile, making it suitable for a diverse array of applications. It is widely used in

1. Construction Serves as structural supports in buildings, ramps, and bridges. 2. Manufacturing Commonly used in creating frames for machinery and equipment.

3. Furniture Often used in the manufacture of sturdy furniture pieces and custom designs.

4. Fencing Employed in the construction of fences and gates due to its strength and weather resistance.

5. Electrical Support Provides a reliable base for conduits and other electrical fittings.

Conclusion

In conclusion, the significance of 4x4 galvanized angle iron cannot be overstated. Its strength, durability, and resistance to corrosion make it an essential component in various construction and manufacturing applications. As factories continue to innovate and improve their manufacturing processes, the demand for this versatile material is likely to grow. As we move towards a future where sustainability and efficiency are paramount, the importance of galvanized angle iron in construction is assured, underpinning modern infrastructure and contributing to successful and enduring architectural projects. Whether in high-rise buildings or simple home renovations, 4x4 galvanized angle iron remains a cornerstone of modern construction practices.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025