Dec . 04, 2024 07:39 Back to list

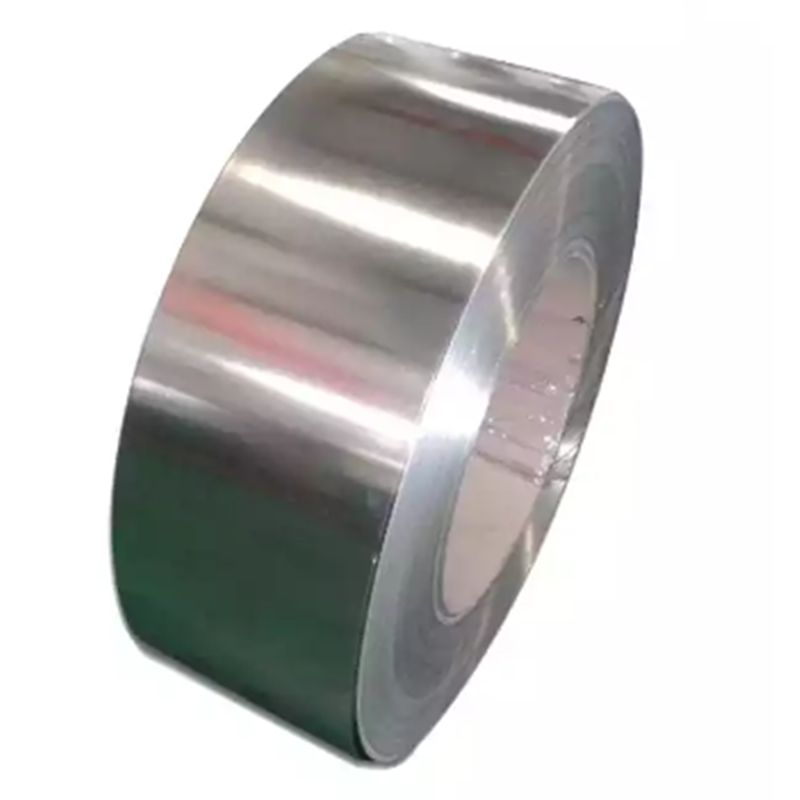

26 Gauge Galvanized Steel Coil Manufacturer for Quality Construction and Industrial Applications

Understanding 26 Gauge Galvanized Steel Coil A Comprehensive Look at its Production and Applications

Galvanized steel, particularly in the form of coils, plays a pivotal role in various industries, from construction to automotive. Among the different gauges available, 26 gauge galvanized steel coil stands out due to its balance of thickness, strength, and versatility. In this article, we will explore the characteristics, manufacturing process, and applications of 26 gauge galvanized steel coils, as well as examine the factors that contribute to their growing popularity.

Characteristics of 26 Gauge Galvanized Steel Coil

First, to understand why 26 gauge galvanized steel coils are favored, it's essential to discuss their properties. A gauge is a measurement of thickness; in the case of 26 gauge, it refers to a thickness of approximately 0.0187 inches or 0.476 millimeters. This thickness provides a suitable combination of durability and lightweight, making it an ideal choice for various construction and manufacturing needs.

The galvanization process—applying a protective zinc coating to steel—enhances resistance to corrosion, making galvanized steel coils suitable for outdoor applications or environments prone to moisture. The zinc layer acts as a sacrificial barrier; even if the coating suffers scratches or abrasions, the underlying steel remains protected from rust.

The malleability of 26 gauge steel also allows it to be formed into various shapes and sizes, adding to its utility across industries. Its ability to withstand extreme weather conditions adds to its desirability for both structural and aesthetic applications.

Manufacturing Process

The production of 26 gauge galvanized steel coils begins with high-quality steel sheets, which are then cleaned and treated to remove impurities. The cleaned sheets are passed through a zinc bath, a process known as hot-dip galvanizing. This method ensures that the zinc adheres well to the steel surface, forming a robust bond that enhances durability.

26 gauge galvanized steel coil factory

After galvanization, the steel coils are rolled and cut to specific lengths based on customer requirements. Quality control is paramount during this phase, with tests performed to ensure that the thickness, zinc coating, and structural integrity of the coils meet industry standards.

Factories that specialize in producing galvanized steel coils often implement advanced technology and equipment to streamline the manufacturing process. Automated systems may be used for handling, cutting, and packaging, ensuring efficiency while minimizing waste.

Applications of 26 Gauge Galvanized Steel Coil

The versatility of 26 gauge galvanized steel coils makes them suitable for a wide range of applications. In the construction industry, these coils are often used to fabricate roofing panels, gutters, and sidings due to their lightweight yet strong properties. The resistance to corrosion also ensures that these components maintain their integrity over time, reducing maintenance costs for building owners.

In the automotive sector, 26 gauge galvanized steel is commonly used in the manufacturing of various vehicle components, including body panels and frames. The protective zinc coating provides necessary corrosion resistance, which is critical for vehicles exposed to harsh environmental conditions.

Moreover, 26 gauge galvanized steel coils are utilized in HVAC systems for ductwork and fittings, ensuring they can withstand thermal expansion and other stressors related to temperature changes and airflow. The versatility of this gauge also extends to appliances, furniture, and even signage.

Conclusion

26 gauge galvanized steel coil is an essential material that combines strength, durability, and versatility, making it a popular choice across various industries. From its robust manufacturing process to its multifaceted applications, it is clear that this gauge of galvanized steel will continue to play a significant role in modernization and construction innovations. As industries evolve and the demand for durable materials increases, understanding the properties and applications of 26 gauge galvanized steel coil becomes increasingly important for engineers, architects, and manufacturers alike.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025