Aug . 25, 2024 10:30 Back to list

26 Gauge Galvanized Steel Coil Manufacturing Process and Quality Standards

Understanding 26 Gauge Galvanized Steel Coil Production

Galvanized steel has become an essential material used in various industries due to its remarkable durability and resistance to corrosion. Among the different specifications available, 26 gauge galvanized steel coil stands out for its versatility, being used in applications ranging from construction to automotive components. This article aims to provide insights into the production of 26 gauge galvanized steel coil and its significance in the market.

The term gauge refers to the thickness of the steel. A 26 gauge sheet measures approximately 0.0187 inches (0.48 mm) in thickness. Galvanization involves coating the steel with zinc to provide an extra layer of protection against rust and corrosion. This process not only extends the lifespan of the material but also enhances its aesthetic appeal, making it an attractive choice for visible structural and decorative applications.

The production of 26 gauge galvanized steel coil typically begins with cold-rolled steel sheets, which are then processed through a galvanizing line. This involves cleaning the steel to remove any impurities, followed by dipping it into a molten bath of zinc. The thickness of the zinc coating can be varied depending on the specific requirements of the end-use application, leading to different grades of galvanized steel.

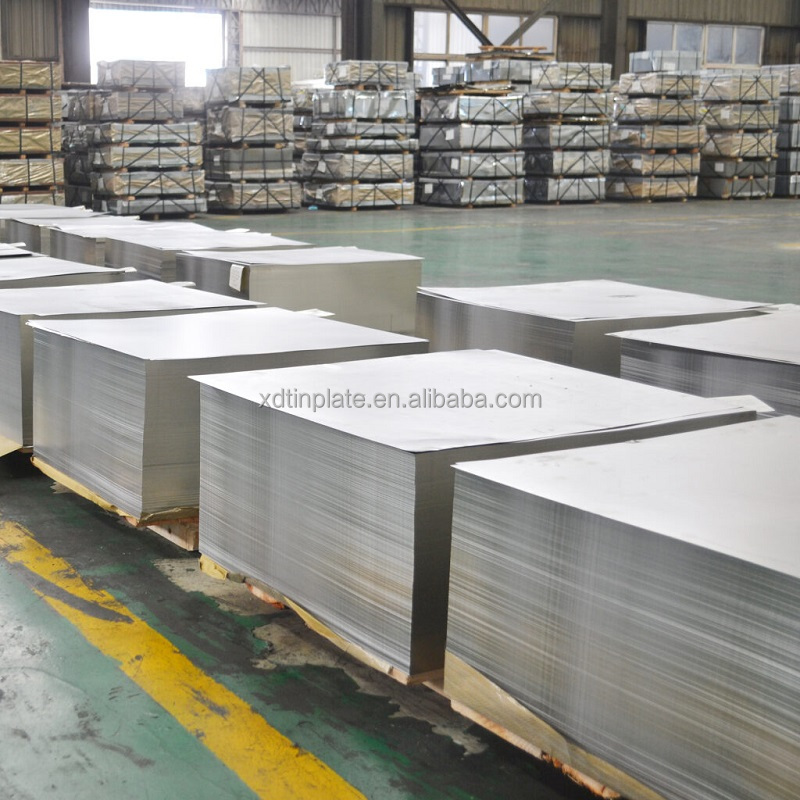

26 gauge galvanized steel coil factory

Once the steel has been galvanized, it undergoes various quality control checks to ensure it meets industry standards. Key factors assessed include the thickness of the coating, the appearance of the surface, and the overall integrity of the steel. A reliable factory will employ rigorous testing protocols to guarantee their products are top-notch and free from defects, thus ensuring customer satisfaction.

The market demand for 26 gauge galvanized steel coils has surged, especially in areas like residential and commercial construction. Its lightweight yet robust nature allows for easy handling and installation, while its corrosion resistance makes it an ideal choice for roofing, siding, and framework. Additionally, the eco-friendliness of galvanized steel, as it is 100% recyclable, appeals to environmentally conscious consumers and companies.

In conclusion, 26 gauge galvanized steel coils are an invaluable material in today's industrial landscape. Their production involves careful processing and adherence to quality standards, making them a reliable choice for various applications. As industries continue to evolve, the demand for durable and sustainable materials like galvanized steel will likely keep growing, affirming its role in the future of construction and manufacturing.

-

New Energy Vehicles: High Endurance & Cost-Performance

NewsAug.27,2025

-

New Electric Vehicles: Explore BYD Cars & Future Energy

NewsAug.26,2025

-

Buy Diamond Plate Tin Factory Direct | Quality & Durable Metal

NewsAug.25,2025

-

BYD Electric Cars: Innovation & Performance EVs

NewsAug.24,2025

-

High Cost Performance: Stylish, High Endurance Devices

NewsAug.23,2025

-

Cheap Car & EV Deals: Used, New Energy & Luxury Electric Vehicles

NewsAug.22,2025