Jan . 12, 2025 09:47 Back to list

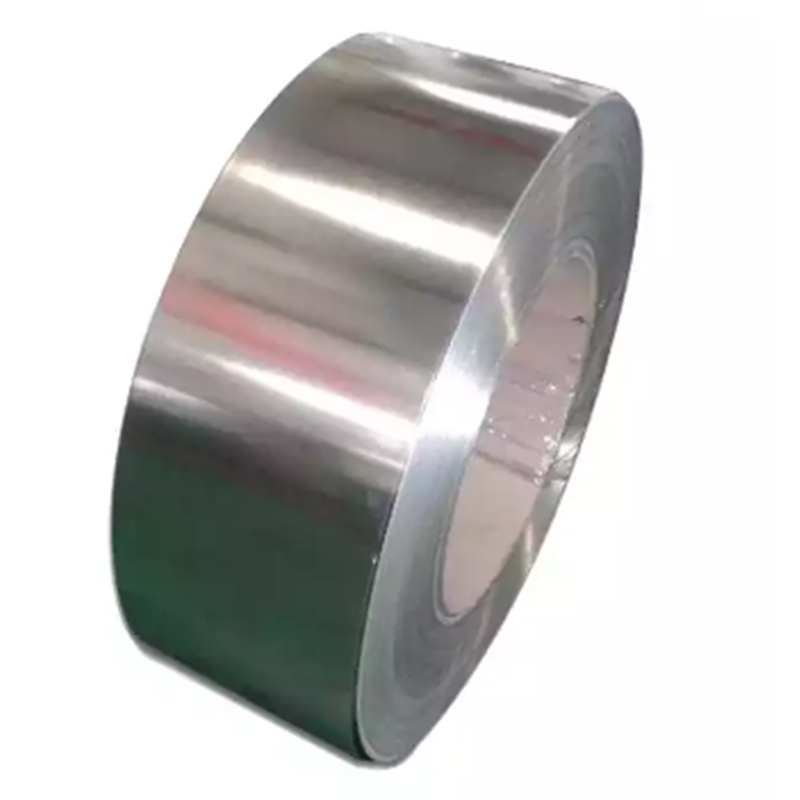

Tinplate T3 T4 600-1050mm tinned steel coil

Exploring the intricacies of 26-gauge galvanized steel coil factories reveals a world defined by precision, durability, and cutting-edge technology. As a widely sought-after product in various industries, including construction, automotive, and manufacturing, the quality and consistency of these steel coils make them indispensable.

Trustworthiness is also paramount in this market. Factories ensure transparency through regular third-party audits and customer feedback loops. A structured approach to addressing customer concerns cultivates a reliable brand image, assuring clients that they are partnering with a reputable manufacturer. Long-standing relationships with international clients further demonstrate reliability and competence in meeting diverse needs. Clients seeking galvanized steel coils often prioritize logistical efficiency and supply chain robustness. Leading factories offer comprehensive logistics solutions, guaranteeing timely delivery across continents. They partner with reliable shipping companies and employ strategic stocking methods to navigate market fluctuations and demand surges deftly. Despite the technical complexities, the human factor in 26-gauge galvanized steel coil production cannot be overlooked. Skilled workers equipped with continuous training form the backbone of these factories, ensuring smooth operations and problem-solving agility. Their expertise contributes significantly to the high standards customers expect and receive. Choosing a 26-gauge galvanized steel coil supplier requires due diligence. Evaluating a factory's technical capabilities, adherence to standards, customer testimonials, and logistical efficiency are crucial steps. An informed choice guarantees not only a superior product but also a beneficial partnership aligned with evolving industry needs. In conclusion, the journey through a 26-gauge galvanized steel coil factory showcases a dynamic interplay of technology, expertise, and trust, resulting in a product that consistently meets the demands of diverse global markets.

Trustworthiness is also paramount in this market. Factories ensure transparency through regular third-party audits and customer feedback loops. A structured approach to addressing customer concerns cultivates a reliable brand image, assuring clients that they are partnering with a reputable manufacturer. Long-standing relationships with international clients further demonstrate reliability and competence in meeting diverse needs. Clients seeking galvanized steel coils often prioritize logistical efficiency and supply chain robustness. Leading factories offer comprehensive logistics solutions, guaranteeing timely delivery across continents. They partner with reliable shipping companies and employ strategic stocking methods to navigate market fluctuations and demand surges deftly. Despite the technical complexities, the human factor in 26-gauge galvanized steel coil production cannot be overlooked. Skilled workers equipped with continuous training form the backbone of these factories, ensuring smooth operations and problem-solving agility. Their expertise contributes significantly to the high standards customers expect and receive. Choosing a 26-gauge galvanized steel coil supplier requires due diligence. Evaluating a factory's technical capabilities, adherence to standards, customer testimonials, and logistical efficiency are crucial steps. An informed choice guarantees not only a superior product but also a beneficial partnership aligned with evolving industry needs. In conclusion, the journey through a 26-gauge galvanized steel coil factory showcases a dynamic interplay of technology, expertise, and trust, resulting in a product that consistently meets the demands of diverse global markets.

Latest news

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025