Dec . 12, 2024 10:28 Back to list

galvanized color coating plant manufacturer

The Rise of Galvanized Color Coating Plants A Comprehensive Overview

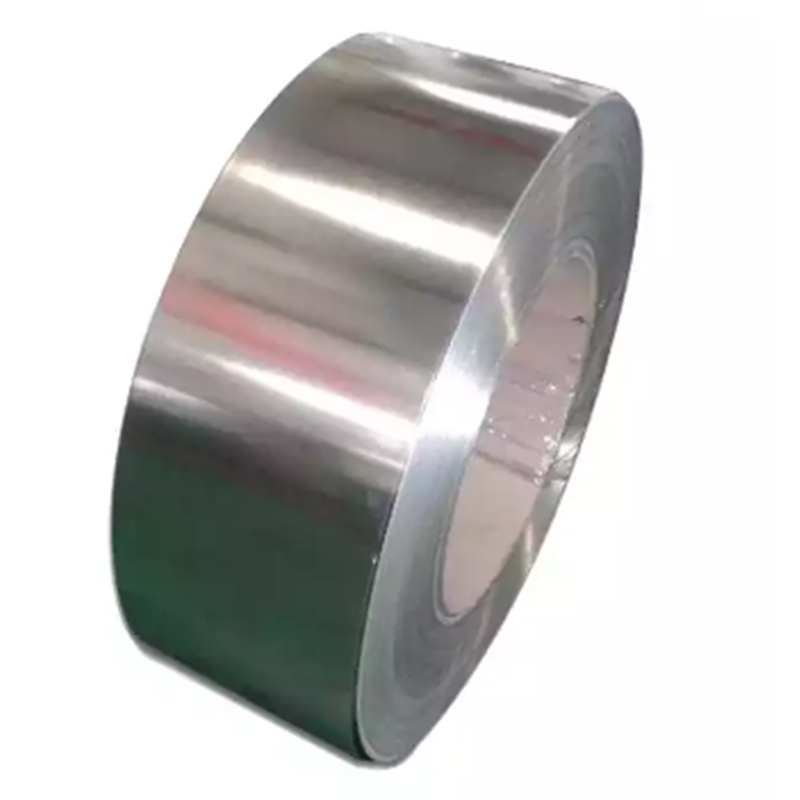

In the modern manufacturing landscape, the demand for high-quality, durable materials is on the rise. Among the various methods of enhancing material resilience and aesthetics, galvanized color coating has emerged as a leading solution. This process not only protects metals from corrosion but also adds an appealing finish. The increasing popularity of this technique has spurred the growth of specialized manufacturers focused on galvanized color coating plants.

Understanding Galvanized Color Coating

Galvanization refers to the application of a protective zinc coating to steel or iron to prevent rusting. This method is particularly effective in environments where exposure to moisture and corrosive materials is common. When combined with color coating, the result is a product that offers both protection and visual appeal. The color coating process typically involves the application of various paints or dyes, which are then cured to create a durable finish.

The advantages of galvanized color coating are manifold. It not only extends the life of the metal but also enhances its aesthetic appeal, making it suitable for a range of applications, from architectural elements to consumer goods. With advancements in technology, manufacturers are able to provide a plethora of color options and finishes, catering to diverse customer preferences.

The Role of Manufacturers

As the market for galvanized color-coated products expands, the role of specialized manufacturers becomes increasingly vital. These manufacturers focus on the design, construction, and operation of galvanizing color coating plants, ensuring that they meet industry standards for efficiency and quality.

1. Design and Engineering A successful coating plant requires careful planning and innovative design. Manufacturers must consider factors such as production capacity, energy efficiency, and the ability to handle different metal substrates. The engineering phase also involves selecting appropriate equipment, including pretreatment systems, coating application units, and curing ovens.

galvanized color coating plant manufacturer

2. Production Technology Advanced technology is crucial in the contemporary coating process. Manufacturers utilize automated systems to guarantee consistent application and minimize waste. Innovations in spray technology, such as electrostatic spray painting, improve adhesion and finish quality, while also reducing environmental impact by minimizing overspray.

3. Quality Control Ensuring the durability and appearance of the finished product is paramount. Leading manufacturers implement rigorous quality control measures throughout the production process. This includes testing for adhesion, thickness, and corrosion resistance to ensure that the finished products meet or exceed industry standards.

4. Environmental Considerations As awareness of environmental issues grows, manufacturers are also focusing on sustainable practices. Many galvanized color coating plants now incorporate eco-friendly materials and processes. This includes the use of water-based paints, recycling systems for wastewater, and reduced energy consumption in curing processes.

Market Trends and Future Outlook

The global market for galvanized color-coated products is expected to continue its upward trajectory. Factors such as urbanization, infrastructure development, and a growing emphasis on aesthetic designs are driving demand across various sectors, including construction, automotive, and consumer goods. As more industries recognize the advantages of galvanized color-coated materials, manufacturers are poised to innovate further and refine their processes.

The future may also see the integration of smart technologies within coating plants. Automation, IoT connectivity, and data analytics can enhance operational efficiency and product monitoring, responding quickly to market changes and customer needs. Moreover, as sustainability practices evolve, manufacturers who adopt green technologies will likely gain a competitive edge.

Conclusion

In conclusion, the galvanized color coating plant manufacturers are at the forefront of a transformative trend within the manufacturing industry. By combining advanced technology with sustainable practices, they are not only meeting the demands of the market but also contributing to a more sustainable future. The versatility and durability of galvanized color-coated products ensure that they will remain a vital component of modern manufacturing, paving the way for continued innovation and growth in the years to come.

-

New & Used Car Deals in New Orleans & NJ Tijara Autos Certified

NewsApr.29,2025

-

How to Use a Paint Pen on a Car Quick Scratch Repair Guide

NewsApr.29,2025

-

Used Smart Cars Under $3k Reliable & Affordable Deals

NewsApr.28,2025

-

Automatic Used Car Dealers Certified Pre-Owned & Affordable Deals

NewsApr.28,2025

-

Mini Prefabrik EV Compact, Energy-Efficient Prefab Housing Solutions

NewsApr.28,2025

-

Sport Durst Certified Pre-Owned Cars Land Rover Deals Near You

NewsApr.28,2025