Dec . 16, 2024 04:50 Back to list

Tin Factory Specializing in Diamond Plate Production and Custom Solutions for Various Industries

The Diamond Plate Tin Factory A Beacon of Craftsmanship and Innovation

In the heart of the industrial district, where the hum of machinery meets the hustle of everyday life, stands the Diamond Plate Tin Factory. Known for its exceptional craftsmanship and commitment to quality, this factory has become a revered establishment in the realm of metalworks, particularly in the production of diamond plate tin products. With roots dating back several decades, it has combined traditional techniques with modern innovations to become a leader in the industry.

Origins and History

The Diamond Plate Tin Factory was founded in the late 1970s by a group of metallurgists and craftsmen who shared a passion for tin plating and metal fabrication. Initially a small workshop, the factory gradually expanded its operations as more clients recognized the superior quality of its products. The name Diamond Plate was inspired by the factory's signature product a durable and aesthetically pleasing sheet of tin featuring a diamond-patterned surface. This unique design not only adds to the visual appeal but also enhances the material's strength and resistance to wear.

Over the years, the factory has built a reputation for excellence, attributed to its skilled workforce and innovative techniques. The team consists of highly trained professionals who understand the intricacies of tin manufacturing, ensuring that every sheet that leaves the factory meets the highest standards of quality and durability.

Production Process

The production of diamond plate tin begins with the selection of raw materials, primarily high-quality steel and tin. The factory prioritizes sustainability, sourcing materials from suppliers who adhere to environmentally friendly practices. Once the materials arrive, they undergo a rigorous process of cutting, shaping, and coating.

The highlight of the production process is the tin plating stage. Tin is electrochemically deposited onto the steel surface, creating a protective layer that enhances corrosion resistance. This step is crucial, as it ensures that the final product is not only visually appealing but also long-lasting. After plating, the sheets are formed into the iconic diamond pattern using advanced machinery that precisely shapes the metal without compromising its integrity.

Quality assurance is a fundamental aspect of the factory's operations. Each batch of diamond plate tin undergoes a series of tests and inspections to guarantee that it meets industry standards. From thickness measurements to corrosion tests, the factory spares no effort in ensuring that its products exceed customer expectations.

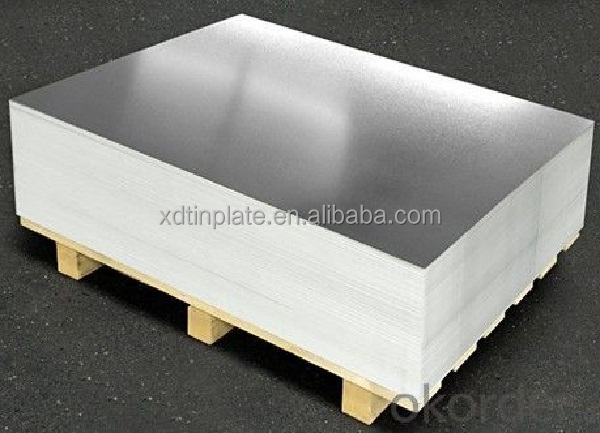

diamond plate tin factory

Applications and Versatility

Diamond plate tin has a wide range of applications across various industries. Its unique combination of aesthetic appeal and durability makes it a popular choice for decorative purposes, including wall accents, signage, and custom display cases. Retailers and interior designers often turn to diamond plate tin for its striking visual effect and ability to complement various styles.

In industrial sectors, diamond plate tin is used for flooring, truck beds, tool boxes, and safety equipment. Its non-slip surface provides an added level of safety in environments where traction is critical. Additionally, the corrosion-resistant properties of tin make it an ideal choice for outdoor applications and harsh environments.

The versatility of diamond plate tin has also made it a favorite among DIY enthusiasts and hobbyists. The ease of cutting and shaping allows individuals to create custom projects, from home decor to art installations, all while benefiting from the material's durability and visual appeal.

Commitment to Innovation

As the industry evolves, the Diamond Plate Tin Factory remains committed to innovation. The management constantly explores new technologies and techniques to improve production efficiency while maintaining quality. Research and development are ongoing, with a focus on developing eco-friendly processes and materials to minimize the factory's environmental impact.

Additionally, the factory places a strong emphasis on customer feedback, ensuring that it remains attuned to the needs and desires of its clients. This customer-centric approach has facilitated the creation of tailored solutions that meet specific requirements, further solidifying the factory's position in the market.

Conclusion

The Diamond Plate Tin Factory stands as a testament to what can be achieved through dedication to craftsmanship, a commitment to quality, and an embrace of innovation. As it continues to produce exceptional diamond plate tin products, the factory not only satisfies the needs of its customers but also contributes to the ongoing legacy of metal fabrication. With each sheet that is crafted, the factory upholds its reputation as a cornerstone of the industry, promising durability, beauty, and a touch of craftsmanship that is truly unmatched.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025