ພ.ຈ. . 03, 2024 12:43 Back to list

paint for galvanized iron factories

Painting Solutions for Galvanized Iron Factories

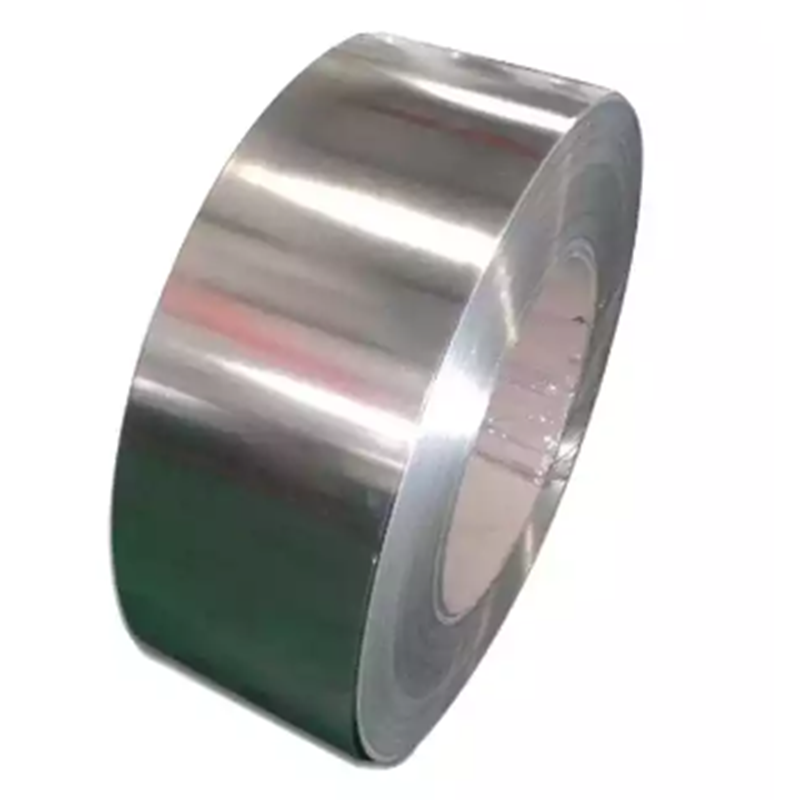

Galvanized iron, known for its exceptional corrosion resistance due to the zinc coating, is widely used in various industrial applications, particularly in factories. However, while the galvanization process provides a robust barrier against rust and wear, there may still be instances where additional protection, aesthetics, or branding is necessary. This is where specialized painting solutions for galvanized iron become essential.

Understanding the Importance of Painting While galvanized iron is inherently resistant to oxidation, its surface can still undergo various environmental stressors, which may lead to an eventual compromise of the zinc layer. Painting galvanized iron not only enhances aesthetic appeal but also adds an extra layer of protection, extending the lifespan of the metal. In industrial settings, where exposure to harsh chemicals, moisture, and extreme temperatures is common, proper paint application can help to mitigate these risks, reducing maintenance costs and downtime.

Painting Solutions for Galvanized Iron Factories

Additionally, the formulation of the paint plays a significant role. Water-based paints are often preferred for indoor applications due to their low volatile organic compound (VOC) content, making them more environmentally friendly and safer for workers. Meanwhile, for outdoor applications, high-performance, weather-resistant coatings that can withstand UV exposure and harsh conditions should be chosen.

paint for galvanized iron factories

Surface Preparation Before applying paint, proper surface preparation is essential. The galvanized surface should be clean and free from any contaminants, such as oil, dust, or rust. A thorough wash with a degreaser followed by rinsing with water is advisable. Light sanding or using a solvent can enhance adhesion by creating a slightly rough surface. For optimal results, it's also recommended to apply a suitable primer designed for galvanized iron before painting.

Application Techniques Painting galvanized iron can be done through various methods including brushing, rolling, or spraying. The choice of application technique depends on the size of the surface and the desired finish. Spraying tends to provide a more even coat, particularly for intricate designs, while brushing offers more control in smaller applications.

Maintenance and Longevity To ensure the longevity of the paint job, regular maintenance checks are advisable. Inspecting for signs of wear or damage, especially in high-wear areas, allows for prompt repairs before extensive deterioration occurs. Simple touch-ups can significantly extend the lifespan of both the paint and the galvanized metal underneath.

Conclusion In conclusion, painting galvanized iron is a valuable practice for enhancing both appearance and durability in factory settings. With careful selection of compatible paints, proper surface preparation, and suitable application techniques, industrial facilities can protect their investments and maintain their structures for years to come. As the industry continues to evolve, embracing innovative painting solutions will ensure that galvanized iron remains a preferred choice for robust and reliable manufacturing environments.

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025