ຕ.ລ. . 31, 2024 01:55 Back to list

galvanized wrought iron manufacturer

The Rise of Galvanized Wrought Iron A Modern Manufacturing Perspective

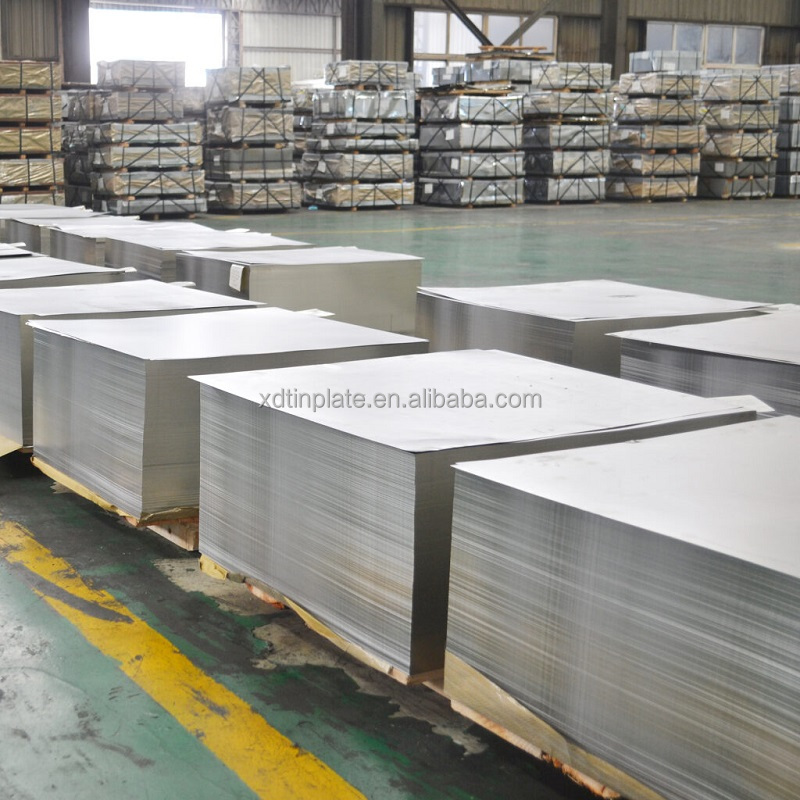

In the world of metalworking, galvanized wrought iron has emerged as one of the preferred materials for construction and various applications. This preference can be attributed to its unique combination of strength, durability, and resistance to corrosion. As a galvanized wrought iron manufacturer, understanding the intricacies of the production process and the advantages of this material can position businesses for success in a competitive market.

Understanding Galvanization

Galvanization is a process that involves coating wrought iron with a protective layer of zinc. This is typically achieved through hot-dipping, where the wrought iron is submerged in molten zinc. The zinc coating forms a barrier that prevents moisture and oxygen from reaching the underlying iron, effectively slowing down the oxidation process. This is particularly important in environments where metal is exposed to moisture, such as coastal areas or regions with heavy rainfall.

Benefits of Galvanized Wrought Iron

One of the primary benefits of galvanized wrought iron is its long lifespan. Without galvanization, wrought iron can succumb to rust and corrosion much faster, dramatically reducing its service life. However, with proper galvanization, it can last for decades, making it a cost-effective solution for long-term projects.

Moreover, galvanized wrought iron is known for its mechanical properties. It maintains high tensile strength, making it ideal for structural applications where load-bearing capacity is crucial. This characteristic is particularly valuable in construction, where safety and reliability are paramount.

Additionally, the aesthetic appeal of galvanized wrought iron cannot be overlooked. The bright, shiny surface of freshly galvanized iron provides an attractive finish that enhances the visual appeal of buildings and products. This is especially important in decorative applications where form is as significant as function.

galvanized wrought iron manufacturer

Manufacturing Process

The manufacturing process for galvanized wrought iron involves several key steps. Initially, wrought iron is shaped and formed into the desired products, which can range from fencing and gates to architectural elements. After shaping, the pieces undergo surface preparation to remove any contaminants, followed by the galvanization process to ensure a clean adhesion of the zinc coating.

Quality control is a critical aspect of manufacturing galvanized wrought iron. Manufacturers must ensure that each piece meets industry standards and specifications. This includes testing the thickness of the zinc coating, checking for any areas of bare metal, and ensuring overall structural integrity.

Market Demand and Future Trends

The demand for galvanized wrought iron is growing, driven by increased construction activities and a rising trend towards sustainable building materials. As more consumers and businesses recognize the benefits of durability and low maintenance, galvanized wrought iron products are set to gain even more popularity.

Furthermore, advancements in galvanization techniques and coatings are continually evolving, leading to enhanced performance characteristics and expanded applications. Manufacturers who stay abreast of these innovations will be well-positioned to cater to a diverse clientele and adapt to changing market needs.

Conclusion

In conclusion, galvanized wrought iron represents a significant advancement in materials technology for construction and manufacturing. As a galvanized wrought iron manufacturer, embracing the benefits of this material and focusing on quality in production can lead to lasting success in the market. With a steady demand and ongoing improvements in manufacturing processes, the future looks bright for those involved in the production of galvanized wrought iron.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025