ພ.ຈ. . 18, 2024 21:56 Back to list

galvanized iron wire ufacturers supplier

The Importance of Galvanized Iron Wire in Modern Manufacturing

Galvanized iron wire has become a staple in various industries due to its unique properties and versatility. Manufacturers and suppliers of galvanized iron wire play a crucial role in providing businesses with high-quality materials that can be used in a multitude of applications. This article explores the characteristics, manufacturing process, applications, and market trends surrounding galvanized iron wire, highlighting why it remains an essential product for many sectors.

Understanding Galvanized Iron Wire

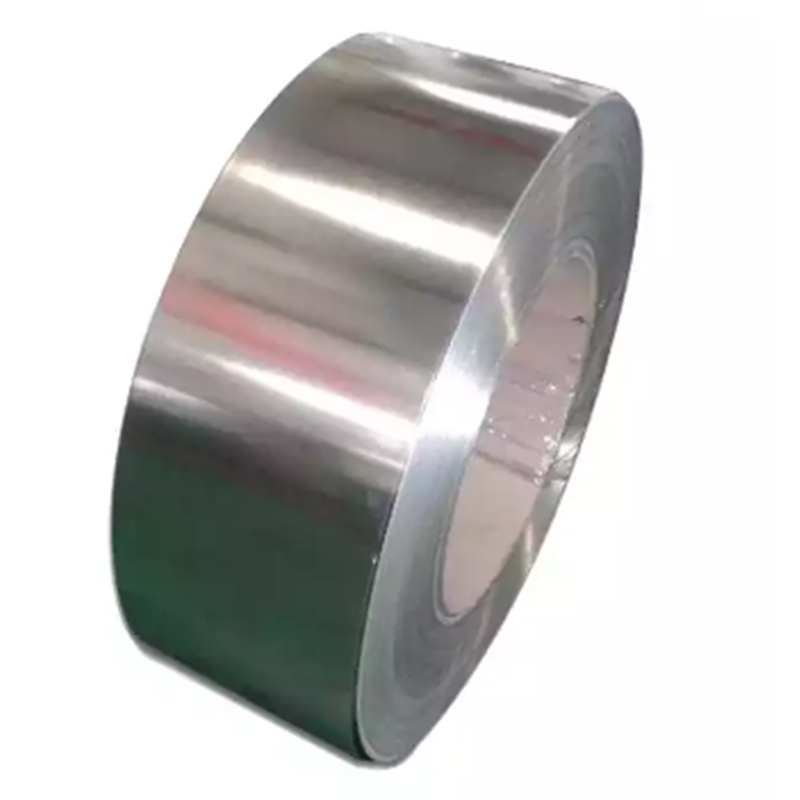

Galvanized iron wire is produced by coating iron or steel with a layer of zinc to prevent rusting. This protective coating is achieved through a process known as galvanization, which involves either hot-dipping the wire in molten zinc or electroplating it. The result is a durable and corrosion-resistant wire that can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications.

Key Characteristics

One of the primary benefits of galvanized iron wire is its resistance to corrosion. The zinc coating acts as a barrier between the iron wire and environmental elements such as moisture and oxygen, which are known to cause rust. This extended lifespan means that businesses can save on maintenance and replacement costs over time.

Another important characteristic is its tensile strength. Galvanized iron wire maintains its strength even in high-stress applications, making it an ideal choice for construction, agricultural projects, and fencing. Additionally, it is highly ductile, allowing it to be easily twisted and shaped into various forms, which adds to its versatility.

Manufacturing Process

The manufacturing of galvanized iron wire typically involves several steps. First, raw iron or steel rods are drawn to create wire of the desired diameter. The wire is then cleaned to remove any surface impurities that could affect the bonding of the zinc. Once cleaned, the wire undergoes the galvanization process, where it is submerged in molten zinc or coated through electroplating. After galvanization, the wire is cooled, possibly resulting in a smoother and more polished finish.

galvanized iron wire ufacturers supplier

Quality control is a critical aspect of the manufacturing process. Reputable manufacturers perform rigorous testing to ensure that the wire meets industry standards for tensile strength, corrosion resistance, and diameter consistency. As a result, businesses can trust that they are receiving a reliable product that meets their specific needs.

Applications of Galvanized Iron Wire

Galvanized iron wire is utilized in a wide range of applications. In the construction industry, it is commonly used for reinforcing concrete structures, tying rebar, and creating mesh for concrete pavements. Its strength and durability make it a preferred choice for scaffolding and temporary supports.

In agriculture, galvanized wire serves as a robust fencing material, protecting livestock and crops from predators while being flexible enough to withstand movement and pressure. Gardeners and landscapers also rely on galvanized wire for trellises, plant supports, and wire cages.

Moreover, manufacturers use galvanized iron wire in producing various products, including nails, staples, and wire hangers. Its versatility extends to crafting, where artists and DIY enthusiasts appreciate its pliability and aesthetic appeal.

Market Trends and Future Outlook

The demand for galvanized iron wire continues to grow, driven by construction, infrastructure development, and the agricultural industry. As urbanization progresses and infrastructure projects expand, the need for durable, long-lasting materials will remain high. Additionally, increased awareness of sustainability and eco-friendly practices is leading manufacturers to invest in greener galvanization techniques, ensuring that the production process minimizes environmental impact.

In conclusion, galvanized iron wire manufacturers and suppliers play a pivotal role in supporting various industries by providing a reliable, durable, and versatile product. With its numerous applications and continuous market demand, galvanized iron wire is likely to maintain its significance in manufacturing and construction for the foreseeable future. Businesses are encouraged to consider the benefits of this material and partner with reputable suppliers to ensure they receive the best products available on the market.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025