ທ.ວ. . 20, 2024 05:59 Back to list

galvanized iron coating suppliers

Exploring Galvanized Iron Coating Suppliers A Comprehensive Insight

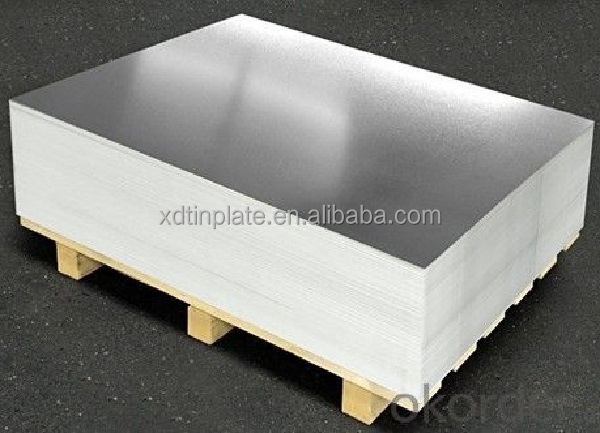

Galvanized iron is a crucial material used across various industries, known for its exceptional resistance to corrosion. The process of galvanization involves coating iron or steel with a protective layer of zinc, which significantly enhances the metal's durability and longevity. As the demand for galvanized iron continues to rise, the role of galvanized iron coating suppliers becomes increasingly important. This article aims to explore the significance of these suppliers, the processes involved in galvanizing, and factors to consider when choosing a supplier.

Understanding Galvanization

Galvanization is a process that involves the application of a zinc coating to iron or steel to prevent rusting. The most common method of galvanization is hot-dip galvanizing, where the iron or steel is submerged in molten zinc. This process creates a strong metallurgical bond, providing the metal with a durable, corrosion-resistant layer. The result is a product that can withstand harsh environmental conditions, making it ideal for outdoor use in construction, automotive, and various industrial applications.

The Role of Galvanized Iron Coating Suppliers

Galvanized iron coating suppliers are integral to the supply chain of construction and manufacturing industries. They provide not only the galvanized materials but also the expertise that comes with understanding the right applications for their products. Suppliers often work closely with manufacturers to ensure that the materials meet specific requirements, such as thickness, coating quality, and adherence to industry standards.

1. Quality Assurance One of the primary responsibilities of galvanized iron coating suppliers is to ensure that the galvanized products meet the required quality standards. This involves rigorous testing for corrosion resistance, coating thickness, and adhesion. Suppliers often provide certifications and reports to their clients, which can be vital for regulatory compliance.

2. Customization Different projects may require specific types of galvanized iron products. Suppliers often offer customization options, such as different finishes, dimensions, and properties suited to the particular needs of a project. This flexibility helps clients maximize the efficacy of their materials in various applications.

3. Technical Support Well-established suppliers provide technical support to their clients. This support can include advice on the appropriate coatings for certain environments, installation guidance, and troubleshooting assistance. Suppliers with extensive knowledge of galvanizing processes and applications can significantly reduce risks associated with material failures.

galvanized iron coating suppliers

Factors to Consider When Choosing a Supplier

When selecting a galvanized iron coating supplier, there are several factors to consider

1. Reputation and Experience Supplier reputation can be a good indicator of the quality of products and services offered. Experienced suppliers often have a history of successful projects and can provide references from previous clients.

2. Product Range Assessing a supplier's product range is essential. A comprehensive selection ensures that you will find the right materials for your specific needs. Suppliers offering a variety of coatings, thicknesses, and finishes can better serve diverse project requirements.

3. Quality Control Measures Understanding a supplier’s quality control processes is crucial. This includes how they ensure the quality of their galvanization process and their compliance with industry standards. Look for suppliers that adhere to ISO certifications or other relevant standards.

4. Customer Service Good customer service is a vital aspect of a successful supplier relationship. Responsive suppliers who communicate effectively and provide timely support can make the sourcing process much smoother.

5. Pricing and Terms While price shouldn't be the only factor in decision-making, it's essential to find a supplier who offers competitive pricing without compromising on quality. Additionally, consider payment terms, delivery timelines, and flexibility in shipping options.

Conclusion

Galvanized iron is an indispensable material in various industries, and the role of galvanized iron coating suppliers cannot be overstated. These suppliers not only provide high-quality materials but also contribute to the success of projects through their expertise and customer support. By understanding the key aspects of galvanization and what to look for in a supplier, businesses can make informed decisions that enhance their operations and ensure the longevity of their structures and products.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025