کانوونی دووەم . 06, 2025 19:07 Back to list

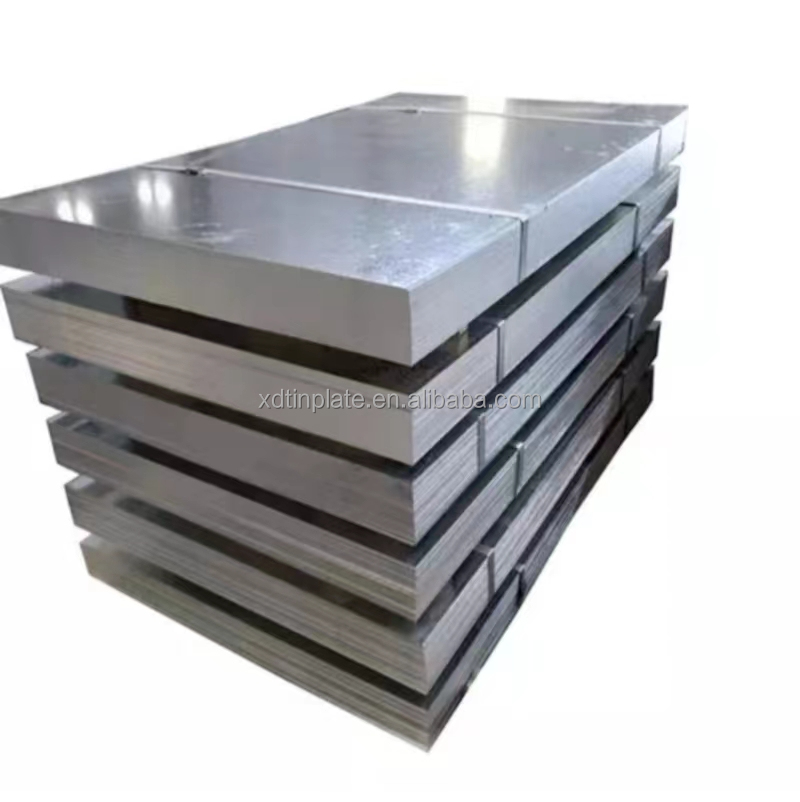

printed tinplate sheet for canned food

Printed tinplate sheets for canned food applications are revolutionizing the packaging industry, combining durability with visual appeal. With over two decades of experience in the field of metallurgical product optimization, I have witnessed firsthand how this versatile material enhances product presentation while ensuring safety.

Tinplate, a material made by coating steel with a thin layer of tin, offers unparalleled resistance to oxidation and corrosion. Its structural integrity ensures that canned food products have an extended shelf life, preventing contamination and maintaining freshness. For manufacturers, choosing printed tinplate is not just about functionality but also about creating a compelling visual link with consumers.

Expertise in tinplate application results in significant advantages. The printability of tinplate sheets allows for customized designs that can boost brand recognition and consumer engagement. Advanced printing techniques can reproduce intricate designs, vibrant colors, and high-definition images, providing a canvas for striking brand storytelling. This asset is particularly invaluable when competing for visibility on increasingly crowded supermarket shelves.

Studies in consumer behavior show that attractive packaging significantly affects purchasing decisions. Utilizing printed tinplate sheets allows food brands not only to shield the product from external factors but also to capture consumer interest through eye-catching designs. From an authoritative standpoint, leading food safety organizations recognize tinplate as a dependable option for food storage due to its non-reactivity with food products and prevention of light infiltration.

printed tinplate sheet for canned food

Trustworthiness in food packaging cannot be overstated. Ensuring consumer safety involves adhering to stringent industry standards. Tinplate canning technology complies with various international regulatory requirements, providing confidence in its use. This compliance is critical for brands looking to maintain consumer trust and loyalty in global markets. Including product certifications and adherence to compliance measures as part of the packaging can further establish credibility.

Incorporating printed tinplate sheets is not only a decision based on performance and branding but also aligns with sustainable practices. Modern tinplate production processes focus on recyclability. The ability to recycle tinplate repeatedly without loss of quality supports environmental goals and reflects a brand's commitment to sustainability.

In conclusion, printed tinplate sheets offer a multifaceted approach to canned food packaging. By integrating experience, expertise, authority, and trust, they represent a comprehensive solution that caters to the evolving needs of both consumers and manufacturers. As the packaging sector transforms, leveraging the unique benefits of tinplate positions brands at the forefront of innovation and reliability.

-

Chery Wujie Pro: Advanced Electric Vehicle for Modern Mobility

NewsJul.26,2025

-

Cost-Effective Tram: Small, Cute, and Efficient EV Car for Urban Travel

NewsJul.25,2025

-

BYD Electric Cars: Innovative New Energy Vehicles & EVs

NewsJul.24,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.23,2025

-

Shop New Car Deals – Reliable, Affordable Options for Every Driver

NewsJul.22,2025

-

Affordable Cheap Cars & EVs: Budget-Friendly Deals

NewsJul.21,2025