تشرینی یەکەم . 22, 2024 06:30 Back to list

olive oil tin can factories

The World of Olive Oil Tin Can Factories

In the heart of Mediterranean countries, the olive oil industry thrives, contributing not only to the economy but also to the culinary heritage of the region. The production and packaging of olive oil have evolved over the years, with tin can factories playing a crucial role in ensuring that this liquid gold reaches consumers in optimal condition. This article explores the significance of olive oil tin can factories, highlighting their processes, benefits, and impact on the industry.

The Importance of Packaging

Packaging is vital in food preservation, particularly for olive oil, which is sensitive to light, heat, and air. High-quality olive oil can degrade quickly when exposed to unfavorable conditions, leading to rancidity and loss of flavor. Tin packaging offers an effective solution to this problem. Unlike glass or plastic, tin cans provide a barrier against light and oxygen, helping to maintain the oil's freshness and taste over time.

Production Process

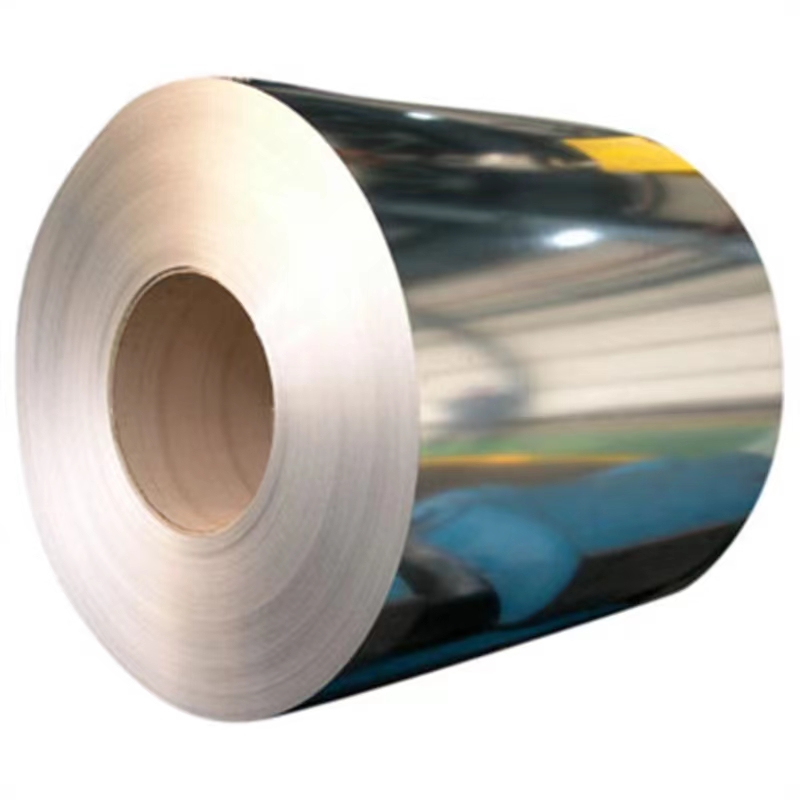

The journey of olive oil tin can production begins with raw materials. Factories source high-quality tinplate, which is produced by coating steel sheets with tin. This material is not only durable but also recyclable, aligning with the growing emphasis on sustainability within the industry. The production process involves several steps, including cutting, shaping, and welding the tin to form cans of various sizes.

Once the cans are ready, they undergo rigorous quality control tests to ensure they meet food safety standards. After passing these checks, the cans are printed with labels that provide vital information, such as the origin of the olives, the harvest date, and the oil's quality grade. This transparency is crucial for educating consumers and enhancing their trust in the product.

Benefits of Tin Packaging

olive oil tin can factories

Tin cans offer numerous advantages for olive oil producers. Firstly, their lightweight nature reduces transportation costs and minimizes the carbon footprint associated with distribution. Additionally, the sturdiness of tin makes it ideal for export, as these containers can withstand rough handling during shipping.

Moreover, tin packaging enhances the branding opportunities for olive oil companies. Custom designs and labeling allow producers to differentiate their products in a crowded marketplace, appealing to consumers who seek authenticity and quality. The aesthetic appeal of nicely designed tin cans also contributes to the overall consumer experience, making them a popular choice for gifting.

Sustainability and Innovation

As the world grapples with environmental challenges, olive oil tin can factories are increasingly adopting sustainable practices. Many factories utilize renewable energy sources in their operations and prioritize recycling efforts. The tin cans themselves are highly recyclable, which resonates well with eco-conscious consumers.

Furthermore, innovations in production technology are paving the way for even more efficient and environmentally friendly manufacturing processes. Advanced equipment can reduce waste and energy consumption, making tin can production more sustainable.

Conclusion

Olive oil tin can factories serve as the backbone of the olive oil packaging industry. By ensuring the quality and longevity of olive oil through effective packaging, these factories contribute significantly to the overall success of the sector. As sustainability becomes a focal point for consumers and producers alike, the role of tin can factories will likely continue to evolve, embracing innovation while honoring the time-honored tradition of olive oil production. In doing so, they not only protect a cherished culinary staple but also promote environmental responsibility and sustainability in the industry.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025