Des . 16, 2024 09:56 Back to list

galvanized iron pipes factory

The Importance of Galvanized Iron Pipes for Industrial Applications

In today's industrial landscape, the usage of specialized materials is paramount to ensuring durability, efficiency, and cost-effectiveness. Among these materials, galvanized iron pipes stand out as a popular choice for various applications, ranging from construction to plumbing. These pipes are coated with a layer of zinc to protect them from corrosion and rust, making them especially suited for environments prone to moisture and other corrosive elements. In this article, we will delve into the characteristics, manufacturing process, applications, and advantages of galvanized iron pipes produced by a dedicated factory.

Characteristics of Galvanized Iron Pipes

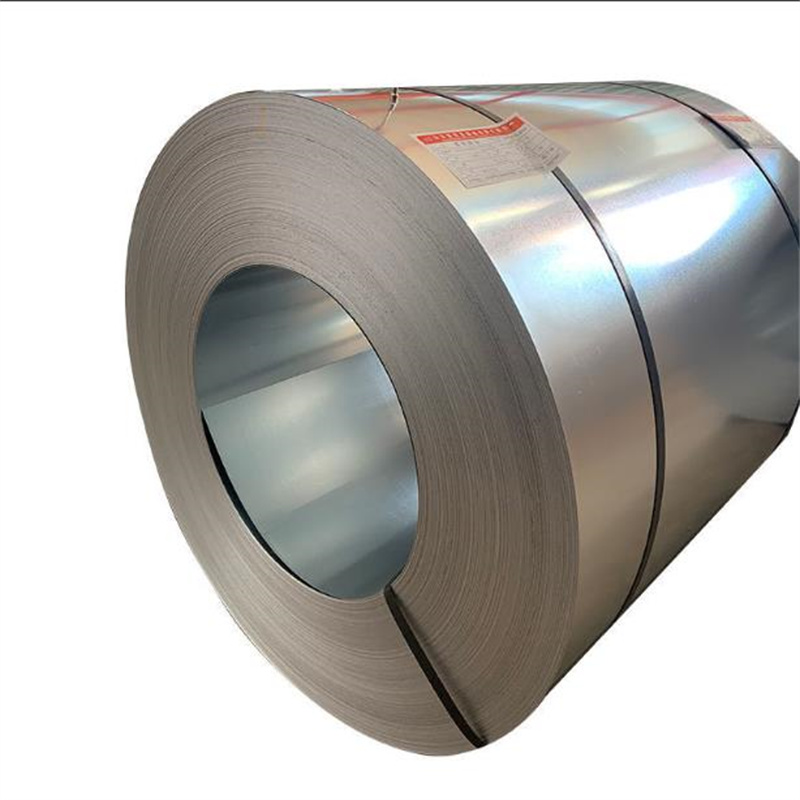

Galvanized iron pipes are well-known for their excellent strength and durability. The galvanization process involves dipping iron or steel pipes into molten zinc, which forms a protective layer that significantly extends their lifespan. This unique coating offers exceptional resistance to corrosion, which is one of the main reasons these pipes are favored in various sectors. The surface finish is smooth, allowing for efficient fluid flow and reducing the potential for blockages.

In addition to their resistance to environmental factors, galvanized iron pipes are robust and can withstand high pressure, making them suitable for a wide range of industrial applications. They are also lightweight compared to other materials such as cast iron, offering ease of handling and installation.

Manufacturing Process

The manufacturing of galvanized iron pipes typically begins with the production of black steel pipes, which are then coated with zinc through either hot-dip galvanization or electro-galvanization. Hot-dip galvanization involves immersing the pre-welded or seamless pipes in a bath of molten zinc, resulting in a thick coating that adheres strongly to the surface. This method provides superior protection against rust and is widely used in industrial manufacturing.

On the other hand, electro-galvanization utilizes an electrolytic process to deposit zinc onto the steel surface. While this method results in a thinner coating than hot-dipped pipes, it provides a smoother finish and can be effective for specific applications where extreme corrosion resistance is not necessary.

Factories focusing on the production of galvanized iron pipes prioritize quality control throughout the manufacturing process

. This includes rigorous testing for strength, coating adherence, and overall performance to ensure that the final products meet industry standards.galvanized iron pipes factory

Applications of Galvanized Iron Pipes

Galvanized iron pipes are versatile and find usage in a multitude of applications. One of the most common is in water supply systems. Their resistance to rust and corrosion makes them ideal for both potable water lines and wastewater management systems. Additionally, these pipes are often used in fencing and scaffolding, providing robust support structures in construction sites.

Moreover, galvanized iron pipes are also employed in agricultural irrigation systems, where efficient water delivery is essential. Their ability to withstand the harsh outdoor conditions while maintaining integrity over time adds to their appeal for farmers.

In the industrial sector, galvanized pipes are utilized in HVAC systems, plumbing, and fire suppression systems, thanks to their ability to handle high-pressure demands without compromising structural integrity.

Advantages of Galvanized Iron Pipes

The benefits of using galvanized iron pipes extend beyond their durability. One significant advantage is their cost-effectiveness; their longevity reduces the need for frequent replacements, thus saving money in the long run. Furthermore, the ease of installation associated with these pipes can lead to lower labor costs compared to more cumbersome alternatives.

Another critical advantage is their environmental impact. The extended lifespan and recyclability of galvanized steel contribute positively to sustainability efforts, as fewer resources are needed for production and maintenance.

Conclusion

In conclusion, galvanized iron pipes manufactured in dedicated factories play a crucial role in various industries due to their remarkable properties and versatility. From water systems to industrial applications, these pipes offer durability, cost savings, and environmental benefits that make them an optimal choice for professionals around the globe. As industries continue to evolve, the demand for reliable, corrosion-resistant materials like galvanized iron pipes will undoubtedly remain steadfast.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025