Oct . 08, 2025 22:30 Back to list

Buy Diamond Plate Tin Factory Direct—Bulk & Custom?

Thinking of sourcing diamond plate tin? Notes from the factory floor

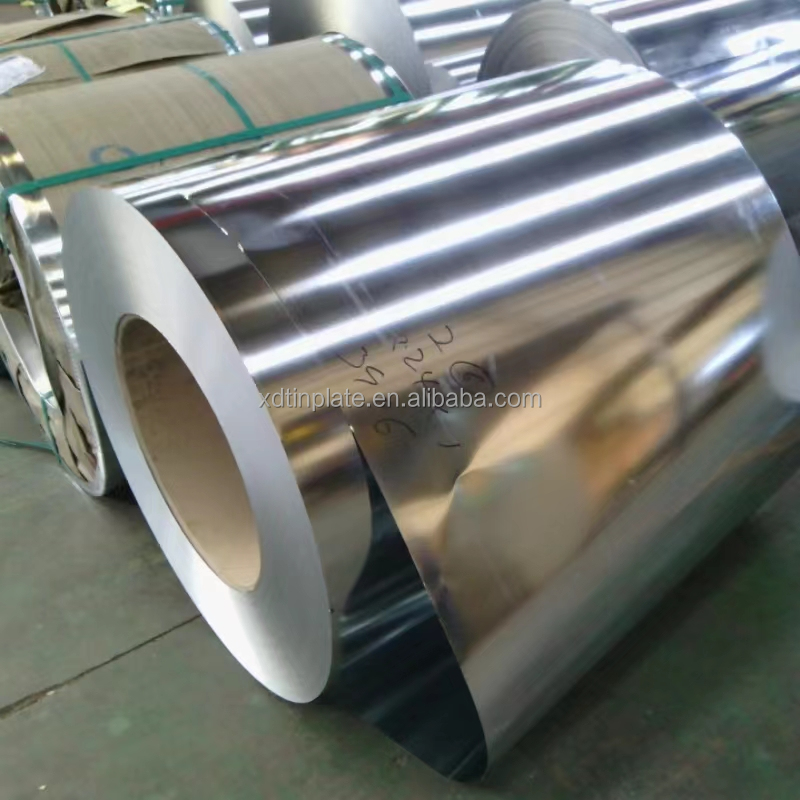

If you’re hunting for a reliable buy diamond plate tin factory, here’s what I’ve learned after too many site visits and a couple of scuffed safety boots. The short version: quality starts with the base steel, and it lives or dies by coating weight, line control, and testing discipline. XD Tinplate in Hebei—yes, the address is Room 1017, Qicheng Building, No.210, ZhongHuanan Street, Qiaoxi District, Shijiazhuang—has been pushing hot-dip galvanized sheets with optional diamond emboss at wholesale pricing. Actually pretty competitive.

What’s trending (and why it matters)

Two clear trends: thinner gauges with higher coating mass, and tighter control of spangle for food/cleanroom-adjacent uses. Many customers say they’re switching from painted aluminum tread to galvanized diamond plate for better dent resistance and easier fabrication. In fact, urban projects want Z275/G90 coatings even on interior traffic surfaces—belt-and-suspenders approach, but understandable.

Core specs at a glance

| Product | Hot-dip galvanized steel sheet (optional diamond emboss) |

| Standards | GB, ASTM A653, JIS G3302, DIN; ISO9001 system |

| Width | ≈ 600–1200 mm |

| Thickness | ≈ 0.13–0.45 mm (real-world use may vary by emboss depth) |

| Coating mass | Z120–Z275 (ASTM G60–G90 equivalent) |

| Mechanical | Yield ≈ 240–350 MPa; Tensile ≈ 270–420 MPa; elongation by grade |

| Finish | Regular/minimized spangle, skin-pass, passivated, lightly oiled |

| Certs | API, CE, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, TISI, KS, JIS, GS, ISO9001 |

From coil to diamond: the process (short version)

Materials: low-carbon cold-rolled steel. Methods: continuous hot-dip galvanizing with air knives; temper rolling; optional chromate-free passivation; oiling. Diamond emboss is applied via patterned work rolls—watch the roll crown and pressure, or you’ll get uneven ridge height (seen it, not pretty).

Testing standards: coating weight by ISO 1460; bend/adhesion per ASTM A653; salt spray exemplar ASTM B117 (typical lab snapshots: Z275 panels ≈ 240–360 h to first red rust at scribe, controlled lab, your mileage may vary). Surface roughness and hardness after skin-pass are logged. Service life: rural 20–30 years, urban/industrial 10–20, marine splash 5–12 unless you upspec coating or add paint.

Where it’s used

Marine walkways, container111 floors, equipment platforms, vehicle interiors, kickplates in food logistics, and yes, shop stairs that get battered daily. One Hebei client told me their warehouse ramps with Z275 diamond plate showed “zero coating lift” after a season of forklifts—gritty but convincing.

Vendor snapshot: what to compare

| Vendor | MOQ | Lead time | Coating/QA | Certs | Customization |

|---|---|---|---|---|---|

| XD Tinplate (Hebei) | ≈ 10–25 tons | 15–25 days | Z120–Z275; ISO 1460, bend test logs | API, CE, RoHS, ISO9001, etc. | Diamond pitch/depth, spangle, oiling, width/length |

| Typical trader | ≈ 25–50 tons | 25–40 days | Z80–Z180; mixed QA records | Basic COC | Limited emboss controls |

| Local mill | Varies | Fast if in stock | Good, but check spangle/flatness | Mill ISO | Depends on roll set availability |

Customization tips

- Specify diamond pitch and rib height (mm). Small pitch improves grip for indoor ramps.

- Choose minimized spangle if aesthetics or hygiene matter.

- For coastal installs, step up to Z275 and consider a topcoat system—honestly worth it.

- Request mill test certificates plus salt spray snapshots; real data beats brochures.

If you contact a buy diamond plate tin factory, ask about bend performance after embossing and whether they temper-roll pre- or post-emboss to stabilize flatness—subtle detail, big result.

Two quick case notes

1) Container yard walkway, Z275, 0.8 mm equivalent after emboss: 12-month inspection showed white rust at cut edges only; edges were unsealed—lesson learned. 2) Food logistics kickplates, minimized spangle, RoHS-compliant passivation: cleaning with neutral detergent kept gloss; no flaking after 180° bend test.

Sources and standards

- ASTM A653/A653M — Steel Sheet, Zinc-Coated (Galvanized)

- ISO 1460 — Metallic coatings — Determination of coating mass

- JIS G3302 — Hot-dip zinc-coated steel sheet and strip

- ASTM B117 — Standard Practice for Operating Salt Spray (Fog) Apparatus

-

Reliable Water Tin Can Suppliers for Durable and Sustainable Water Storage

NewsNov.24,2025

-

Water Tin Can Factory: Sustainable Solutions for Safe Water Packaging

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturer for Durable Infrastructure Solutions

NewsNov.23,2025

-

Trusted Galvanized Malleable Iron Manufacturers | Durable & Custom Iron Components

NewsNov.22,2025

-

Galvanized Malleable Iron Factories – Durable & Cost-Effective Industrial Solutions

NewsNov.22,2025

-

Galvanized Malleable Iron Supplier: Durable & Sustainable Industrial Components

NewsNov.21,2025