नवम्बर . 12, 2024 15:30 Back to list

tin can bulk manufacturers

Understanding the Landscape of Tin Can Bulk Manufacturers

In the realm of packaging, few materials have proven as reliable and versatile as tin cans. Often associated with food and beverage storage, tin cans have become a staple in various industries since their inception in the early 19th century. Today, bulk manufacturers of tin cans are playing an essential role in meeting the demands of a global market that increasingly values sustainability, efficiency, and innovation.

The Importance of Tin Cans in Packaging

Tin cans are highly favored due to their durability, resistance to corrosion, and ability to preserve contents for extended periods. These advantages contribute to their widespread use in the food and beverage sectors. According to the Food and Agriculture Organization (FAO), the preservation of food in canned form helps reduce waste and ensures that nutritious options are available year-round. This stability makes tin cans a go-to choice for manufacturers looking to minimize losses while ensuring product integrity.

Bulk Manufacturing Process

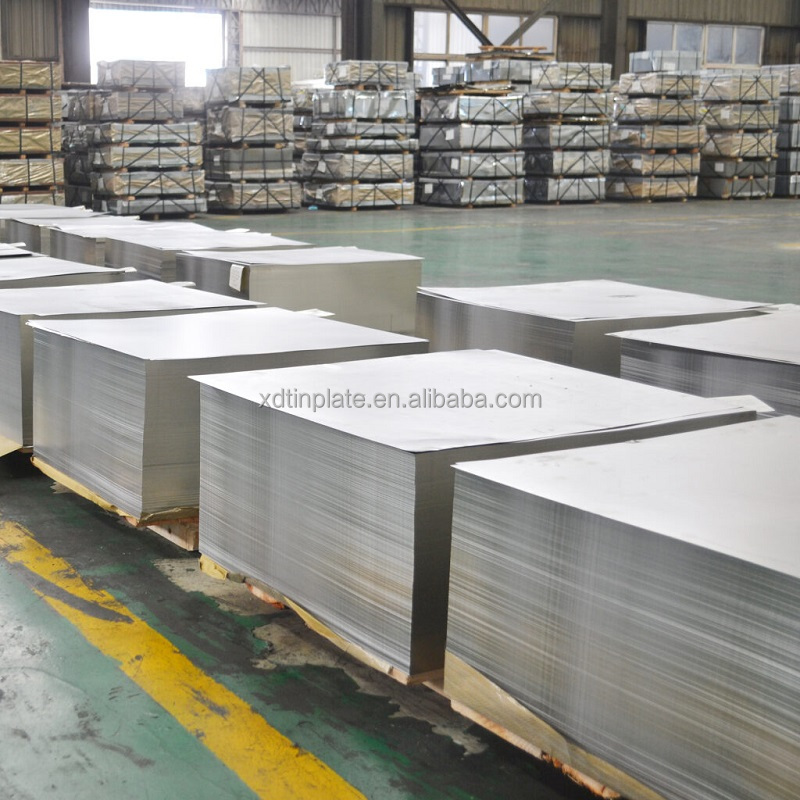

The process of bulk manufacturing tin cans involves several stages, beginning with the sourcing of high-quality materials. Manufacturers typically utilize steel sheets coated with tin to produce these cans. The sheets are rolled and cut into specific shapes, which are then formed into can bodies.

One of the critical elements of bulk manufacturing is automation. Modern production lines utilize advanced machinery that can produce thousands of cans per hour. This efficiency not only meets the rising demand for canned products but also reduces labor costs and minimizes the risk of human error. State-of-the-art welding techniques are employed to ensure that seams are secure without compromising the can's integrity.

Sustainability and Environmental Impact

tin can bulk manufacturers

In today's market, sustainability is more than just a buzzword; it's a driving factor for both consumers and manufacturers. Tin cans are fully recyclable, and many bulk manufacturers are focusing on employing greener practices in their production processes. The recycling of tin is energy-efficient, requiring 74% less energy than producing new tin from raw materials. As a result, consumers and businesses alike are increasingly turning to packaging solutions that not only protect products but also contribute to a circular economy.

Moreover, some companies are incorporating recycled tin into their manufacturing processes, thus reducing the need for virgin materials and minimizing their ecological footprint. By investing in sustainable practices, tin can bulk manufacturers are not only aligning themselves with global trends but also paving the way for future innovations in packaging.

The Global Market for Tin Can Manufacturers

The market for tin can manufacturers operates on a global scale, with significant players based in regions like North America, Europe, and Asia. The demand for canned goods continues to grow, with emerging economies showing an increased interest in packaged foods and beverages. For instance, markets in Asia, particularly China and India, are experiencing a surge in demand driven by their expanding middle-class populations and a rising preference for convenience foods.

Manufacturers must, therefore, remain agile and adaptable in their production capabilities to cater to varying market needs. This includes not only producing standard sizes and shapes but also offering customizations that can help brands differentiate themselves in a competitive marketplace. With the rise of e-commerce, manufacturers are also refining their logistics to ensure timely delivery and efficient distribution of their products.

Conclusion

As we move forward, tin can bulk manufacturers are poised to adapt and innovate in a rapidly changing landscape. With a focus on sustainability, efficiency, and responsiveness to market demands, these manufacturers will continue to play a crucial role in the global packaging industry. By embracing new technologies and practices, the future for tin can manufacturers looks promising, ensuring that they meet the needs of consumers while contributing positively to the environment. The humble tin can may be a small component of the packaging ecosystem, but its impact is undoubtedly significant, and its capabilities continue to expand.

-

Cost-Effective Tram: Your New Cute Mini EV Car

NewsAug.06,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025