दिसम्बर . 28, 2024 16:14 Back to list

Manufacturers of Galvanized Iron Yield Strength for Enhanced Construction Performance

Understanding Galvanized Iron Yield Strength Insights from Manufacturers

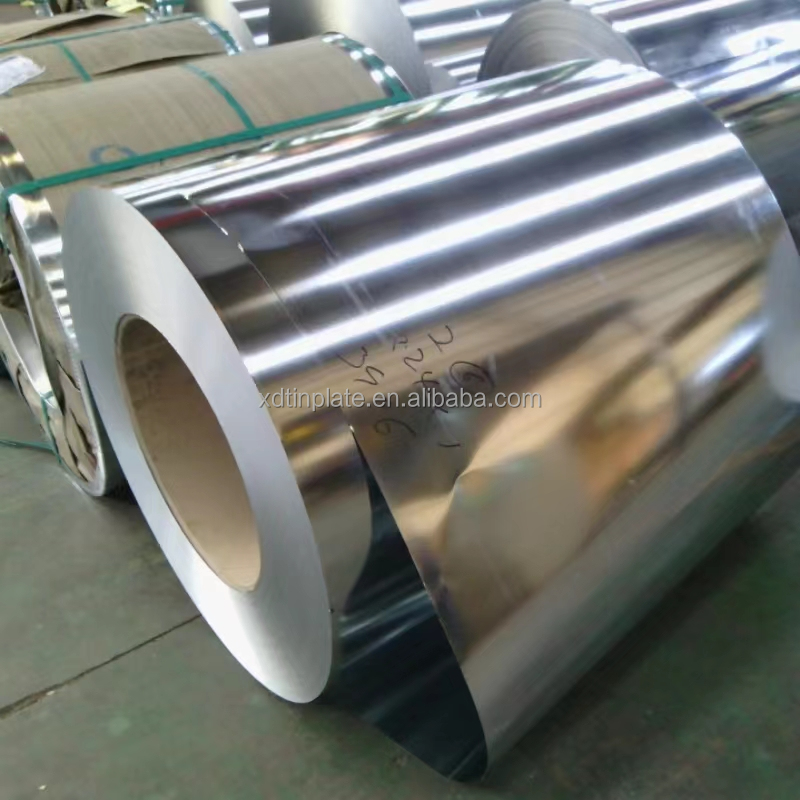

Galvanized iron is a popular material known for its durability, resistance to corrosion, and versatility in a range of applications. Widely used in construction, automotive, and various industrial sectors, galvanized iron is iron or steel that has been coated with a layer of zinc to protect it from rust and environmental wear. One of the crucial properties that manufacturers and engineers focus on when dealing with galvanized iron is its yield strength.

What is Yield Strength?

Yield strength is defined as the amount of stress that a material can withstand before it begins to deform permanently. In simpler terms, it indicates the maximum stress a material can endure without losing its original shape. For manufacturers, understanding the yield strength of galvanized iron is essential as it helps determine the appropriate applications for the material and ensures that structures can withstand loads and stress without structural failure.

Importance of Yield Strength in Galvanized Iron

When it comes to galvanized iron, the yield strength is influenced by several factors, including the thickness of the metal, the manufacturing processes, and the coating methods used. Generally, galvanized iron has a yield strength ranging between 230 to 500 MPa (megapascals), which can vary based on specific grades and treatments. This range makes galvanized iron suitable for medium to heavy-duty applications where strength and durability are paramount.

A higher yield strength often means a thinner gauge of material can be used without compromising structural integrity. This is particularly beneficial in construction and manufacturing, where weight savings can lead to lower costs and improved efficiency. For instance, in the automotive industry, using materials with high yield strength allows for lighter vehicles without sacrificing safety and performance.

galvanized iron yield strength manufacturers

Factors Affecting Yield Strength in Galvanized Iron

Several factors can influence the yield strength of galvanized iron. The quality of the base metal used, the process of galvanization, and the environmental conditions the material will face all play significant roles. Manufacturers must maintain strict quality control measures to ensure that the galvanized iron produced meets the desired yield strength specifications.

1. Base Metal Quality The yield strength of galvanized iron begins with the quality of the underlying steel or iron. Higher quality base metals will naturally lead to higher yield strength in the finished product. 2. Galvanization Process The method of galvanization, whether hot-dip or electro-galvanization, also impacts the final properties of the metal. Hot-dip galvanization typically results in a thicker coating and better protection, while electro-galvanization can provide a more uniform coating but may not be as robust under certain conditions.

3. Environmental Factors Exposure to various environmental conditions can affect the yield strength over time. Manufacturers need to consider the intended use of galvanized iron products and the environments they will face, addressing concerns such as humidity, temperature variations, and exposure to harmful chemicals.

Choosing the Right Manufacturer

When sourcing galvanized iron, it is crucial to work with reputable manufacturers that prioritize quality and adhere to industry standards. Potential buyers should evaluate manufacturers based on their experience, quality control processes, and the certifications they possess. It is also beneficial to inquire about the specific yield strength of their products to ensure they meet project requirements.

In conclusion, yield strength is a critical property of galvanized iron that significantly influences its usability across various industries. Manufacturers must understand the factors that affect yield strength to produce reliable materials that serve their intended purposes effectively. As technology advances, we can expect improvements in manufacturing processes and material treatments that will further enhance the yield strength and overall performance of galvanized iron products. This will ensure that galvanized iron remains a staple in construction and manufacturing for years to come.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025