नवम्बर . 05, 2024 12:31 Back to list

corrugated stainless steel sheet metal factory

Corrugated Stainless Steel Sheet Metal Factory A Look Into Modern Production and Applications

In the world of metal manufacturing, corrugated stainless steel sheet metal stands out for its unique properties and versatile applications. This robust material is not only aesthetically pleasing but also offers durability, strength, and resistance to corrosion, making it a preferred choice in various industries. The production processes within a corrugated stainless steel sheet metal factory showcase advanced technology and skilled craftsmanship, resulting in high-quality products that meet the demands of modern architecture, construction, and manufacturing.

Understanding Corrugated Stainless Steel Sheet Metal

Corrugated stainless steel is characterized by its wavy surface, which is not merely for visual appeal. The corrugation enhances the structural integrity of the sheets, providing strength while maintaining a lightweight profile. Such features make it ideal for use in roofing, wall cladding, and even as a decorative element in interiors. Stainless steel, known for its resistance to rust and staining, is an excellent choice for environments that require materials to withstand harsh conditions—be it in industrial settings or outdoor applications.

The Manufacturing Process

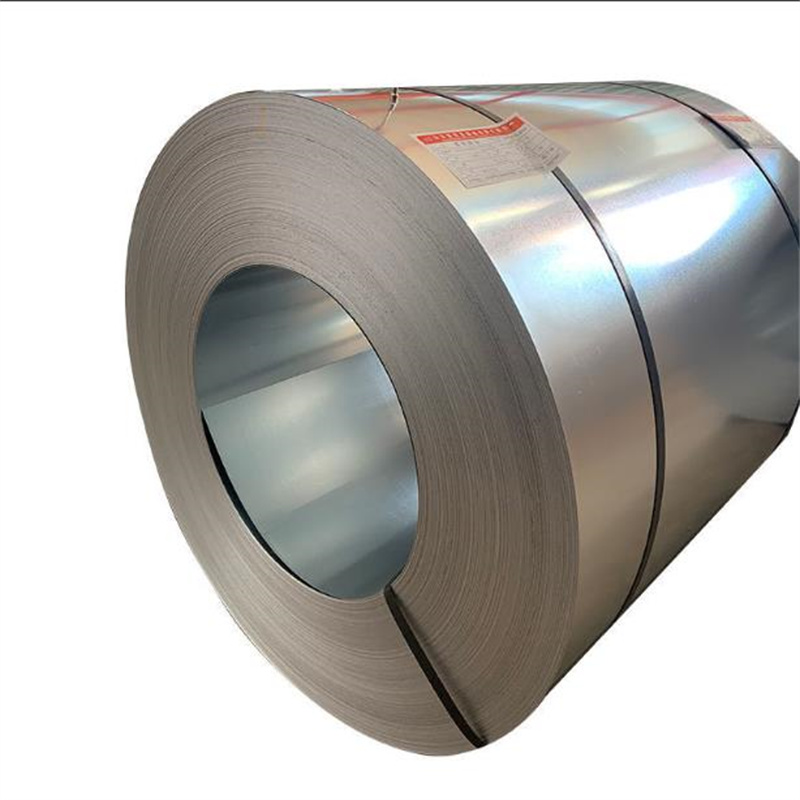

The production of corrugated stainless steel sheet metal begins with high-quality stainless steel coils. These coils are sourced from reputable suppliers who ensure that the raw materials meet stringent quality standards. The manufacturing process typically involves several crucial steps, including

1. Uncoiling The stainless steel coils are uncoiled and fed into a corrugating machine.

2. Corrugating Using advanced machinery, the flat sheets undergo a process of forming corrugations. This step may involve passing the sheets through a series of rollers that impart the desired wave shapes. The depth and frequency of the corrugations can be customized based on specific requirements.

3. Cutting Once the corrugation is complete, the sheets are cut to the specified lengths. Precision cutting is vital to ensure that the dimensions meet client specifications.

corrugated stainless steel sheet metal factory

4. Surface Treatment Depending on the intended application, the sheets may undergo various surface treatments. This can include polishing for aesthetic purposes or applying protective coatings to enhance corrosion resistance.

5. Quality Control At every stage of production, rigorous quality control measures are implemented. Each batch is tested to ensure it meets the necessary standards for strength, durability, and finish.

6. Packaging and Distribution Once completed, the corrugated stainless steel sheets are carefully packaged to prevent any damage during transportation. They are then distributed to various industries, including construction, automotive, and manufacturing.

Applications in Various Industries

The versatility of corrugated stainless steel sheet metal makes it suitable for a wide range of applications. In the construction sector, these sheets are often used for roofing and siding due to their durability and weather resistance. Buildings designed with corrugated stainless steel not only benefit from structural strength but also present a modern and sleek aesthetic.

In the automotive industry, corrugated stainless steel is sometimes used in the production of lightweight components, such as panels and chassis. The material's ability to resist damage from environmental factors, coupled with its lightweight nature, allows manufacturers to create vehicles that are both efficient and durable.

Moreover, the food processing and chemical industries rely heavily on stainless steel’s hygienic properties. Corrugated sheets are often utilized in the construction of storage tanks, processing plants, and other facilities where cleanliness and resistance to corrosion are paramount.

Conclusion

The corrugated stainless steel sheet metal factory plays a crucial role in providing high-quality materials that meet the diverse needs of various industries. With advanced manufacturing techniques and stringent quality controls, these factories ensure that their products not only fulfill functional requirements but also contribute to the architectural beauty of modern structures. As industries continue to evolve, the importance of durable, versatile materials like corrugated stainless steel will remain pivotal in driving innovation and progress.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025