דצמ . 13, 2024 01:53 Back to list

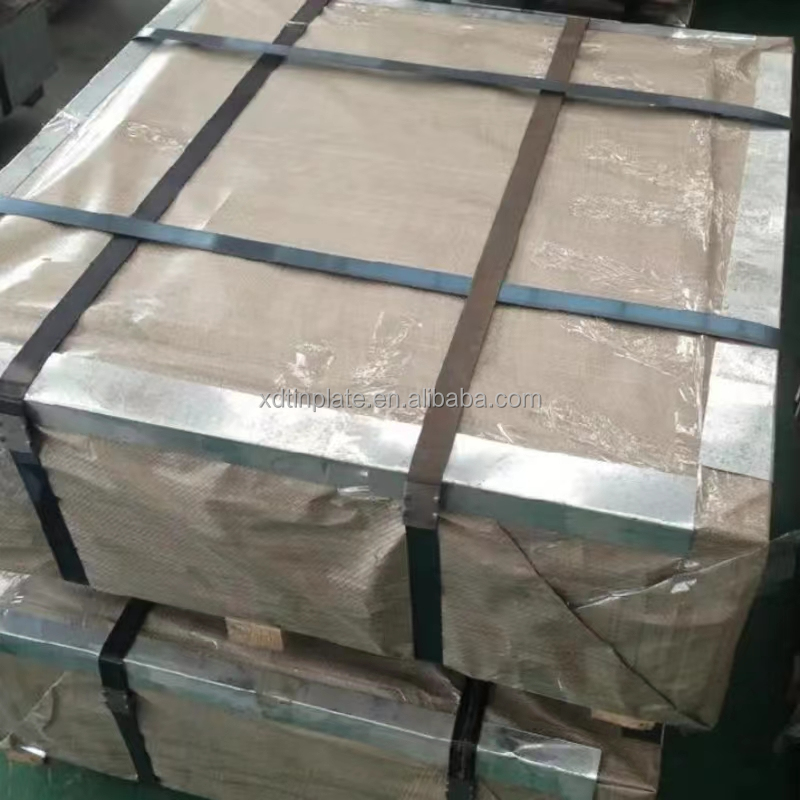

printed tinplate sheets suppliers suppliers

The Role of Printed Tinplate Sheets in Modern Manufacturing and Their Suppliers

In the realm of manufacturing, materials play a critical role in defining both the functionality and aesthetics of products. Among these, printed tinplate sheets have gained significant prominence due to their unique properties and versatile applications. Tinplate, primarily composed of steel coated with a thin layer of tin, offers a combination of strength, malleability, and corrosion resistance. When printed, these sheets can elevate the appeal of a product, making them a go-to choice for various industries, including packaging, automotive, and consumer goods.

Understanding Printed Tinplate Sheets

Printed tinplate sheets are essentially steel sheets that have been coated with tin and then printed with various designs, logos, or patterns. This printing can be conducted using a variety of techniques including lithography, digital printing, and screen printing, ensuring high-quality visuals that do not fade easily over time. These sheets are typically used for the manufacturing of cans, closures, and containers, as well as for decorative purposes in various consumer goods.

The advantages of using printed tinplate sheets extend beyond mere aesthetics. Not only are they lightweight and durable, but they also provide an excellent barrier against moisture, light, and gases, which is crucial for preserving the freshness of food and beverages. Additionally, the tin coating acts as a protective layer that prevents rust and corrosion, making tinplate an ideal choice for packaging and storage solutions.

Market Demand and Applications

The demand for printed tinplate sheets is on the rise, driven by the expanding packaging industry, especially in sectors such as food and beverage. As consumers become increasingly environmentally conscious, the recyclability and sustainability of tinplate also enhance its appeal. Manufacturers are adapting to market trends by focusing on creating aesthetically pleasing packaging that not only protects products but also attracts consumers on the shelves.

Furthermore, printed tinplate sheets find their place in various non-food applications. They are commonly used in the automotive industry for manufacturing components, decorative trim, and protective covers, as well as in electronics for casing and shielding. Their versatility makes them suitable for a plethora of industries, reinforcing their importance in the supply chain.

Choosing the Right Suppliers

printed tinplate sheets suppliers suppliers

When it comes to sourcing printed tinplate sheets, selecting the right supplier is crucial for ensuring product quality, reliability, and timely delivery. Numerous suppliers specialize in providing high-quality tinplate products, but not all are created equal. Manufacturers need to evaluate potential suppliers based on a few key criteria

1. Quality Assurance The supplier should adhere to industry standards and regulations, ensuring that the products meet the required specifications and quality benchmarks.

2. Customization Options Many manufacturers require bespoke designs or specific dimensions for their products. Therefore, a supplier offering custom printing and sizing options can be invaluable.

3. Sustainability Practices With the push for sustainable manufacturing, suppliers that utilize eco-friendly materials and processes can appeal to businesses striving for greener operations.

4. Delivery and Logistics Timely delivery is vital in maintaining production schedules. Suppliers with robust logistics capabilities and a track record of reliability can prevent unnecessary delays and support manufacturing continuity.

5. Technical Support A knowledgeable supplier who can provide technical assistance and guidance in selection and application can help manufacturers navigate challenges and optimize their use of tinplate products.

Conclusion

Printed tinplate sheets are essential for modern manufacturing, combining functionality with aesthetic appeal across various industries. As demand for these materials grows, the role of suppliers can significantly influence production outcomes. By selecting reliable and capable suppliers, manufacturers can ensure they harness the full potential of printed tinplate sheets, driving innovation and enhancing product offerings in an increasingly competitive market. Ultimately, the evolving landscape of consumer preferences and sustainability initiatives will continue to shape the future of printed tinplate, affirming its place as a vital component in industrial manufacturing.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025