Feb . 16, 2025 08:09 Back to list

china cost of sheet metal for roof

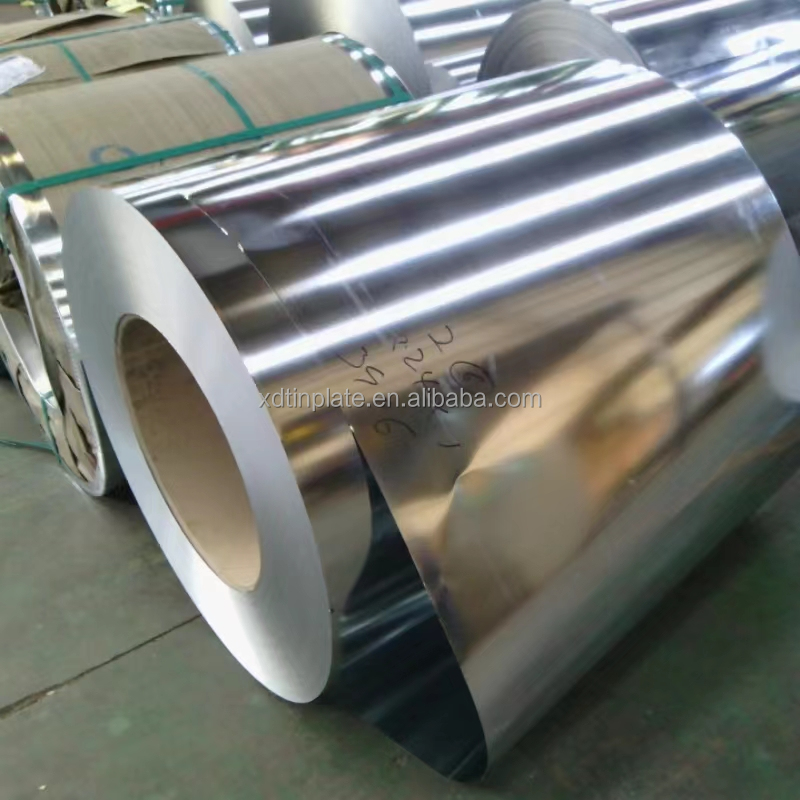

Metal roofing has steadily gained traction among homeowners and builders for its durability, aesthetic appeal, and energy efficiency. As these roofs become more popular, understanding the cost implications, particularly the price per sheet from the factory, becomes critical for cost-effective decision-making. This guide aims to provide a comprehensive understanding of metal roof costs per sheet directly from the factory while underscoring the factors that could influence pricing.

When evaluating factory direct pricing, warranty offers and quality assurance should not be overlooked. A factory offering an extended warranty could be indicative of the product's resilience and the manufacturer's confidence in its durability. Always verify the specifics of warranty coverage, and consider these warranties in the overall price analysis. For builders and developers, engaging directly with the factory allows for customization of the roofing sheets. This customization can include specific sizes, finishes, or colors that might not be available off-the-shelf from retail suppliers. Tailoring products to meet the unique specifications of a project often justifies a higher initial cost because of the potential savings in installation time and reduced waste. Moreover, environmentally conscious consumers will find it appealing that factory orders can support sustainability goals. Metal is inherently recyclable, and factories are increasingly adopting eco-friendly production processes which reduce the overall carbon footprint associated with metal roofing products. Understanding factory direct pricing not only involves examining the cost per sheet but also scrutinizing the relationship between quality, durability, and aesthetic appeal. By balancing these factors, stakeholders can ensure that they select a product that suits both budgetary constraints and project specifications while maintaining the integrity and aesthetic qualities desired in a metal roofing system. Purchasing metal roofing direct from the factory can be a savvy economic choice, bolstered by numerous advantages ranging from cost savings and customization to direct control over logistics. Through careful assessment of the available options, one can secure a high-quality product tailored to their project's unique needs while remaining financially prudent.

When evaluating factory direct pricing, warranty offers and quality assurance should not be overlooked. A factory offering an extended warranty could be indicative of the product's resilience and the manufacturer's confidence in its durability. Always verify the specifics of warranty coverage, and consider these warranties in the overall price analysis. For builders and developers, engaging directly with the factory allows for customization of the roofing sheets. This customization can include specific sizes, finishes, or colors that might not be available off-the-shelf from retail suppliers. Tailoring products to meet the unique specifications of a project often justifies a higher initial cost because of the potential savings in installation time and reduced waste. Moreover, environmentally conscious consumers will find it appealing that factory orders can support sustainability goals. Metal is inherently recyclable, and factories are increasingly adopting eco-friendly production processes which reduce the overall carbon footprint associated with metal roofing products. Understanding factory direct pricing not only involves examining the cost per sheet but also scrutinizing the relationship between quality, durability, and aesthetic appeal. By balancing these factors, stakeholders can ensure that they select a product that suits both budgetary constraints and project specifications while maintaining the integrity and aesthetic qualities desired in a metal roofing system. Purchasing metal roofing direct from the factory can be a savvy economic choice, bolstered by numerous advantages ranging from cost savings and customization to direct control over logistics. Through careful assessment of the available options, one can secure a high-quality product tailored to their project's unique needs while remaining financially prudent.

Latest news

-

New Energy Vehicles: High Endurance & Cost-Performance

NewsAug.27,2025

-

New Electric Vehicles: Explore BYD Cars & Future Energy

NewsAug.26,2025

-

Buy Diamond Plate Tin Factory Direct | Quality & Durable Metal

NewsAug.25,2025

-

BYD Electric Cars: Innovation & Performance EVs

NewsAug.24,2025

-

High Cost Performance: Stylish, High Endurance Devices

NewsAug.23,2025

-

Cheap Car & EV Deals: Used, New Energy & Luxury Electric Vehicles

NewsAug.22,2025