נוב . 26, 2024 23:19 Back to list

Galvanized Iron Pipe Manufacturers for Reliable Water Supply Solutions

Understanding Galvanized Iron Pipes for Water Supply A Comprehensive Overview

Galvanized iron pipes have been a staple in the construction and plumbing industries for decades, particularly in water supply systems. These pipes, coated with a layer of zinc to prevent rusting, are known for their durability and resistance to corrosion. This article explores the manufacturing process, benefits, applications, and considerations of using galvanized iron pipes for water supply.

The Manufacturing Process

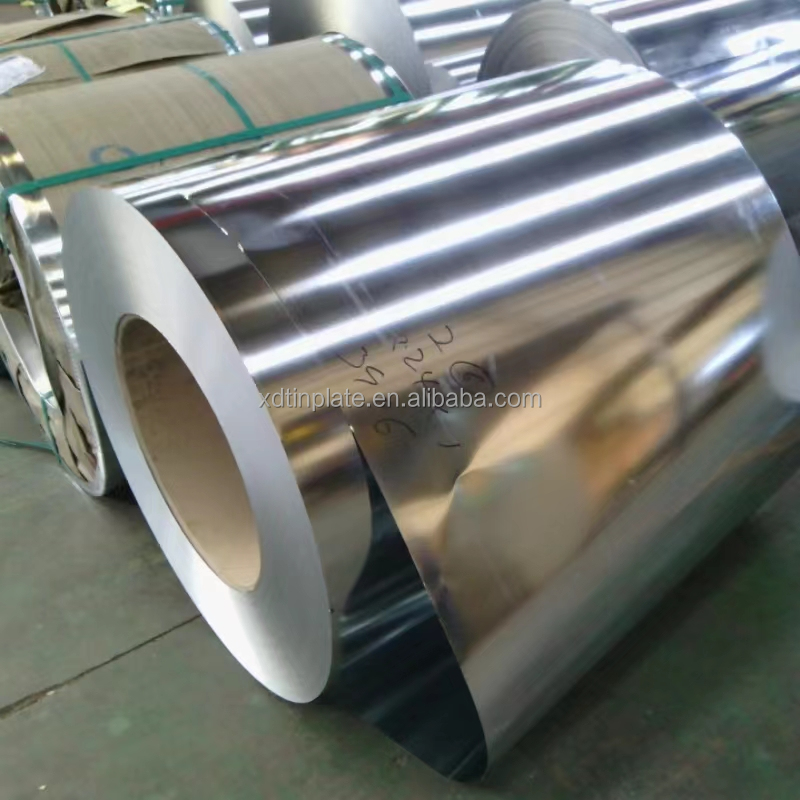

The production of galvanized iron pipes involves several key steps. Initially, steel or iron is drawn into the desired pipe shape and size. The raw material undergoes a thorough cleaning process to remove any impurities or grease that could compromise the quality of the galvanization. Once cleaned, the pipes are immersed in a bath of molten zinc, a method known as hot-dip galvanization. This process ensures a thick, even coating that bonds to the iron, providing excellent protection against environmental factors causing corrosion.

After galvanization, the pipes are cooled, cut to specific lengths, and may be subjected to further quality checks to ensure they meet industry standards. Manufacturers continuously innovate to improve the durability and performance of these pipes, often incorporating advanced technologies to enhance the bonding of the zinc coating and optimize the manufacturing process.

Advantages of Galvanized Iron Pipes

1. Corrosion Resistance The primary benefit of galvanized iron pipes is their resistance to rust and corrosion. This makes them particularly suitable for water supply applications, where exposure to moisture can lead to rapid degradation of conventional iron pipes.

2. Durability Galvanized iron pipes are known for their strength and longevity. Properly installed and maintained, they can last for decades, making them a cost-effective solution for water supply systems.

3. Low Maintenance Unlike plastic pipes, which may become brittle over time, galvanized iron pipes require minimal maintenance. Their robust nature ensures that they can withstand the rigors of fluctuating temperatures and pressures.

galvanized iron pipe for water manufacturer

5. Recyclable Material In addition to their utility, galvanized iron pipes are primarily made from recyclable materials, contributing positively to environmental sustainability efforts.

Applications

Galvanized iron pipes are widely used in various industries. Their primary application is in residential and commercial water supply systems, where they transport drinking water and wastewater. Additionally, they are used in agricultural irrigation systems, construction projects involving plumbing needs, and even in industrial settings for transporting chemicals.

Considerations

Despite their numerous advantages, there are some considerations to keep in mind when using galvanized iron pipes. Over time, the internal coating can degrade, leading to a buildup of mineral deposits that may affect water flow and quality. Furthermore, in situations involving highly acidic or alkaline water, the longevity of galvanized pipes can be compromised.

As the industry evolves, alternatives such as PEX and PVC pipes have gained popularity due to their lighter weight and flexibility. Nonetheless, galvanized iron pipes remain a trusted choice for many applications.

Conclusion

Galvanized iron pipes have established themselves as a reliable and enduring option for water supply systems. Their strength, resistance to corrosion, and longevity make them an attractive choice for both residential and industrial applications. Understanding the manufacturing process, benefits, and limitations of galvanized iron pipes can help stakeholders make informed decisions regarding their use in water supply infrastructure. As technology advances, the ongoing development of these pipes promises to enhance their performance and sustainability, ensuring they remain a key player in plumbing and construction for years to come.

-

Discover Cheap Cars with GPT-4 Turbo Deals | Save Big Now

NewsAug.04,2025

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025