Déc . 04, 2024 23:35 Back to list

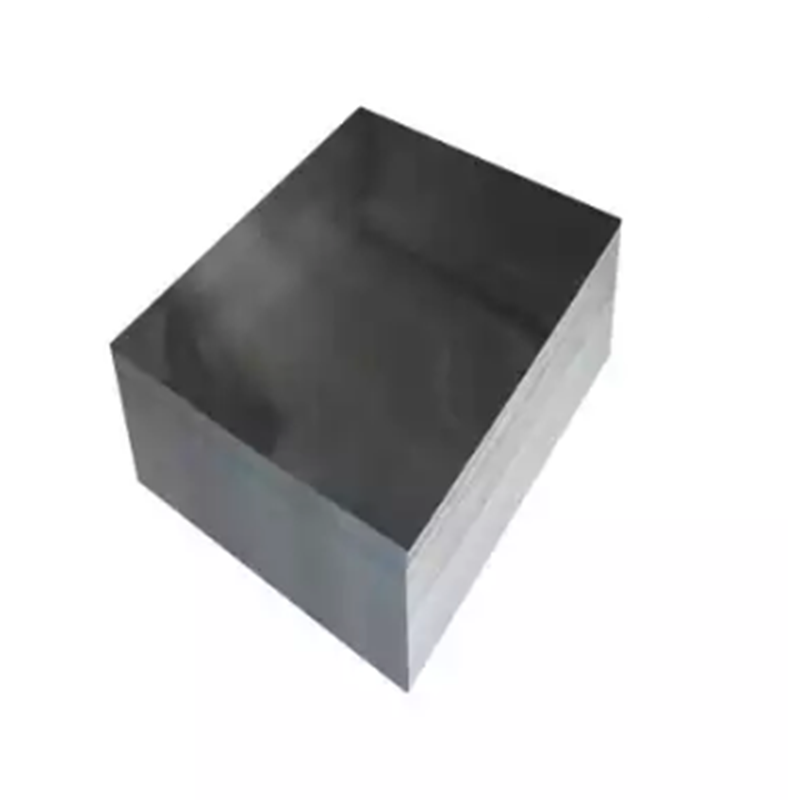

tin plate factory factory

The Tin Plate Factory An Insight into Modern Production

In today's industrial landscape, the tin plate factory stands as a vital hub for the production of tin-coated steel sheets, which are essential in various industries, especially for packaging applications. Tin plates are renowned for their excellent corrosion resistance, making them ideal for food and beverage packaging, electronics, and automotive components. This article explores the operations, significance, and technological advancements within a modern tin plate factory.

The Production Process

The production of tin plates begins with high-quality steel sheets, typically cold-rolled steel, which are the primary raw material

. The process can be categorized into several key stages pickling, annealing, tinning, and final coating.1. Pickling The cold-rolled steel sheets are first pickled in an acidic solution to remove impurities such as rust, scale, and oxides. This step is crucial as it enhances the surface quality of the steel, ensuring better adhesion of subsequent coatings.

2. Annealing Once cleaned, the sheets undergo an annealing process, where they are heated to improve their ductility and mechanical properties. This treatment helps to relieve internal stresses within the material, preparing it for further processing.

3. Tinning The core of tin plate production is the tinning process. The clean, annealed steel is electroplated with a thin layer of tin. This layer serves as a barrier against corrosion and provides a suitable surface for printing and other applications. The tinning process can be achieved through hot-dipping or electrolytic methods, with the latter allowing for more precise control over the thickness of the tin layer.

4. Final Coating After tinning, some products may undergo additional processes such as applying a protective coating or performing further surface treatments. This ensures that the tin plates meet the specific requirements of their end-users, such as food safety regulations or resistance to scratches and chemicals.

tin plate factory factory

Importance in Industry

The significance of a tin plate factory extends beyond mere production. Tin plates are integral to packaging solutions, especially for food items. Their non-toxic and inert properties make them a preferred choice for preserving the freshness of canned goods, beverages, and perishable products. Moreover, the recyclability of tin plates aligns with global sustainability efforts, making them an environmentally friendly option in the packaging industry.

Additionally, tin plates are also used in automotive and electrical industries for parts that require corrosion resistance and durability. Their application in these sectors showcases the versatility and functional benefits of tin-coated materials.

Technological Advancements

As industries evolve, so do the technologies employed in tin plate production. Modern factories are increasingly adopting automation and advanced manufacturing techniques to enhance efficiency and minimize waste. For instance, precision in the tinning process can be improved through advanced control systems that monitor and adjust parameters in real-time.

Moreover, innovations in surface treatment technologies have led to the development of high-performance coatings that further enhance the properties of tin plates. These advancements not only improve product quality but also expand the range of applications that tin plates can serve.

Conclusion

The tin plate factory represents a crucial component of the industrial ecosystem, producing materials that are essential for a variety of applications. As technology continues to advance and environmental considerations take precedence, the tin plate industry is poised for growth and adaptation. By prioritizing innovation and sustainability, tin plate factories can ensure their relevance in an ever-changing market, continuing to meet the diverse needs of industries worldwide.

-

Best PA Used Cars for Sale Reliable Ready Credit & Pyramid Used Cars Mike Hill Used Cars Deals

NewsJul.04,2025

-

Car Parts Used Auto Parts Market – Affordable & Quality Car-Parts.com Selection

NewsJul.04,2025

-

Best Used Cars Kalamazoo Affordable & Reliable Vehicles for Sale in Michigan

NewsJul.04,2025

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025