Déc . 10, 2024 23:55 Back to list

Standard Sizes and Types of Roof Sheets for Industrial Applications

Understanding Standard Roof Sheet Sizes in the Manufacturing Industry

In the construction and manufacturing industry, selecting the appropriate materials is crucial for ensuring structural integrity, durability, and aesthetic appeal. One of the fundamental components in roofing systems is the roof sheet, which serves as a protective layer against environmental elements. This article examines the standard roof sheet sizes that are commonly manufactured, their applications, and factors influencing their selection.

What are Roof Sheets?

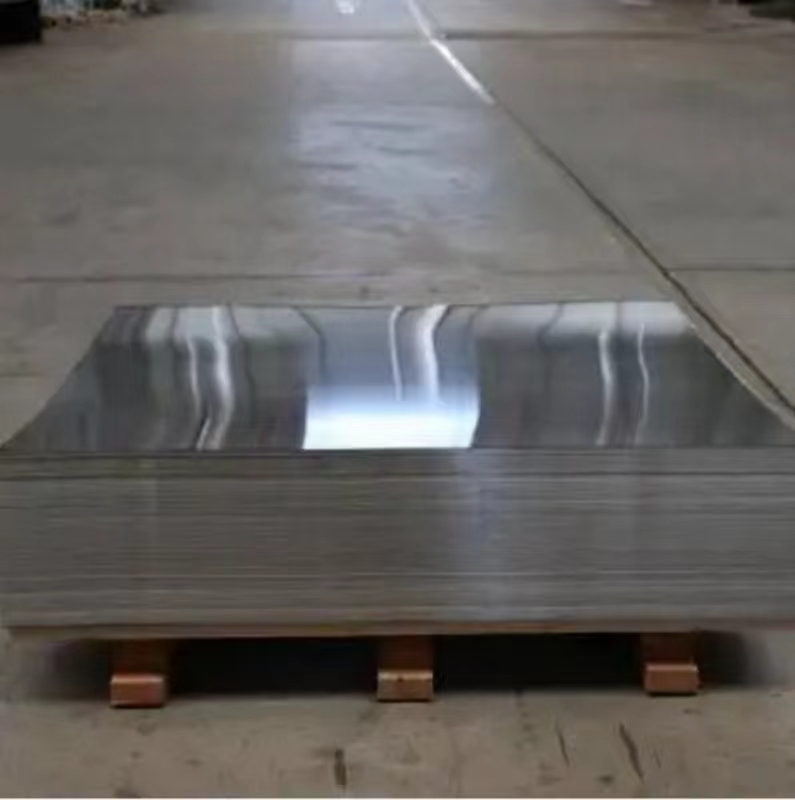

Roof sheets are flat or corrugated panels typically made from materials such as metal, plastic, or fiberglass. They are used in various applications, including residential, commercial, and industrial roofing. The sheets are designed to provide strength, weather resistance, and insulation properties, depending on the specific needs of the building.

Standard Sizes of Roof Sheets

In the factory setting, roof sheets are produced in a range of standard sizes to accommodate diverse building specifications. The most common dimensions are usually 3 feet (0.9 meters) to 4 feet (1.2 meters) in width and lengths ranging from 6 feet (1.8 meters) to 30 feet (9.1 meters).

1. Width The standard widths of roof sheets can vary depending on the intended application. For residential roofs, sheets are often available in widths of 3, 4, or 5 feet. Commercial or industrial applications might require wider sheets, extending up to 6 feet or more.

2. Length The length of roof sheets is typically customizable to minimize waste and optimize installation efficiency. Common lengths include 10, 12, 20, and 24 feet. However, some manufacturers also offer sheets up to 50 feet for large commercial projects.

3. Thickness Besides width and length, the thickness of the roof sheets is another critical measurement. Typically, sheet thickness can range from 0.4mm to 1.0mm for metal sheets, influencing their strength and insulation properties.

Applications of Roof Sheets

The choice of roof sheet size can significantly impact the intended application. For instance, in residential buildings, standard roof sheets are often sized to fit standard rafter spacings, making them easier to install. On the other hand, larger, industrial projects may require customized sizes to span wide areas without sagging or requiring additional support.

standard roof sheet size factory

Different applications will also dictate the choice of material. For instance

- Metal Roof Sheets Commonly used in both residential and commercial applications, available in various finishes such as galvanized steel, aluminum, or copper. They are resistant to weather and provide longevity. - Plastic and Fiberglass Sheets Often used in areas requiring natural light while still providing waterproof protection. They are popular for greenhouses, canopies, and industrial buildings.

Factors Influencing the Selection of Roof Sheets

When choosing roof sheets, several factors must be considered to ensure suitable performance

1. Weather Resistance Areas prone to harsh climates require roof sheets that can withstand wind, rain, snow, and UV exposure.

2. Aesthetic Preferences The visual appeal of roof sheets matters, particularly in residential settings. Available colors and textures can influence exterior design.

3. Insulation Needs Depending on the use of the space beneath the roof, adequate insulation can necessitate the use of composite roof sheets or additional insulation layers.

4. Local Building Codes It's essential to adhere to local regulations regarding roofing materials, which can affect the selection of standard sizes and types of sheets.

5. Cost Efficiency Budget constraints will also influence the choice of materials, sizes, and overall design. Balancing quality and cost is key to a successful project.

Conclusion

In conclusion, understanding standard roof sheet sizes and their applications in the manufacturing industry is vital for anyone involved in construction or roofing projects. Selecting the right size ensures optimal installation, aesthetic appeal, and the necessary protection against elements. As manufacturers continue to innovate and adapt to the needs of the market, the options for roof sheets will only expand, offering even greater versatility for various applications.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025