Nov . 24, 2024 09:09 Back to list

home roof sheet factories

The Home Roof Sheet Industry An Overview of Factories and Their Innovations

In the ever-evolving world of construction and building materials, home roof sheet factories play a crucial role in providing durable, efficient, and cost-effective roofing solutions. Roof sheets are essential components for both residential and commercial buildings, ensuring protection against the elements while contributing to aesthetic appeal. This article explores the significance of home roof sheet factories, their manufacturing processes, innovations in materials, and the challenges they face in today’s market.

Understanding the Role of Roof Sheets

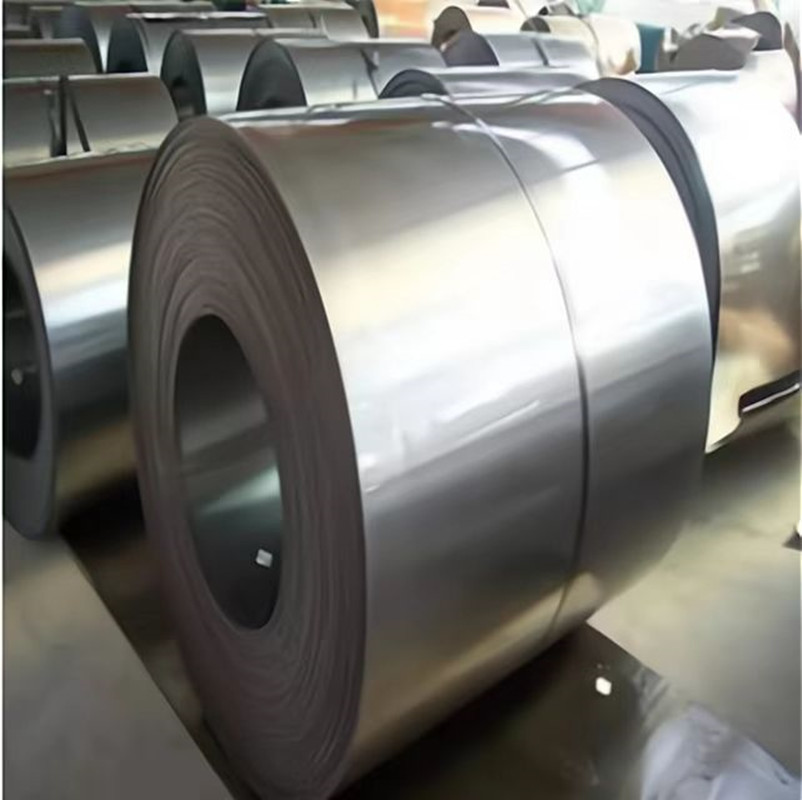

Roof sheets are manufactured from various materials, including metal, plastic, and composite materials, each offering unique advantages. Metal sheets, especially those made from galvanized steel or aluminum, are favored for their strength and longevity. On the other hand, plastic sheets, such as polycarbonate or fibreglass, are preferred for their lightweight properties and transparency. Composite materials combine the benefits of different substances, creating versatile roofing solutions that cater to diverse architectural needs.

The primary purpose of these sheets is to provide structural support and insulation, while also being resistant to weather conditions such as rain, snow, and UV rays. As building designs become increasingly diverse and complex, the demand for innovative roofing solutions continues to grow.

Manufacturing Processes in Roof Sheet Factories

Home roof sheet factories utilize advanced manufacturing processes to meet increasing consumer demands. The production typically involves several stages, starting with raw material preparation followed by shaping, cutting, and coating.

1. Raw Material Selection The choice of materials greatly affects the overall quality of roof sheets. Factories often source high-grade metals or recycled plastics that not only enhance durability but also promote sustainability.

2. Shaping and Forming The manufacturing process involves techniques such as roll forming and extrusion. Roll forming uses continuous rolls of metal to create long sheets, while extrusion is common for producing plastic sheets in various profiles.

3. Finishing and Coating To enhance the longevity of roof sheets, factories apply protective coatings. Galvanization and paint finishes are often used to prevent rust and increase resistance to UV rays.

home roof sheet factories

4. Quality Control Rigorous quality control measures ensure that the finished products meet industry standards. This includes testing for tensile strength, corrosion resistance, and thermal performance.

Innovations in the Roofing Sector

The home roof sheet industry has witnessed significant innovations aimed at improving performance and sustainability. Advanced technologies, such as solar-integrated roofing sheets, allow homeowners to harness solar energy without compromising aesthetic value. Additionally, companies are increasingly adopting eco-friendly materials and processes, including the use of recycled materials in production.

Smart roofing technologies are also on the rise, incorporating sensors that can monitor temperature and moisture levels. These innovations help homeowners manage energy efficiency better, potentially leading to reduced energy costs.

Challenges Facing Roof Sheet Factories

Despite the advancements, home roof sheet factories face several challenges. Fluctuations in raw material prices, environmental regulations, and competition from alternative roofing products are significant hurdles. Moreover, the need for skilled labor in manufacturing processes and innovation remains a pressing issue.

In response to these challenges, many factories are exploring automation and investment in training programs to improve productivity and maintain high-quality outputs. Collaboration with architects and builders can also foster innovation and tailor products to meet specific market needs.

Conclusion

Home roof sheet factories are vital to the construction industry, evolving constantly to meet modern demands. Through advanced manufacturing techniques, innovative materials, and smart technologies, these factories are redefining what roofing can be. As they navigate challenges, their capacity for adaptation and innovation will determine their success in an increasingly competitive market, ensuring continued protection and value for homeowners across the globe. The future of roofing looks promising, with factories playing a pivotal role in shaping sustainable and efficient building practices.

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025

-

EV Car for Eco-Friendly Driving | Mini EV & New Energy Vehicles

NewsJul.28,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Green Future

NewsJul.27,2025

-

Chery Wujie Pro: Advanced Electric Vehicle for Modern Mobility

NewsJul.26,2025

-

Cost-Effective Tram: Small, Cute, and Efficient EV Car for Urban Travel

NewsJul.25,2025

-

BYD Electric Cars: Innovative New Energy Vehicles & EVs

NewsJul.24,2025