Déc . 12, 2024 10:30 Back to list

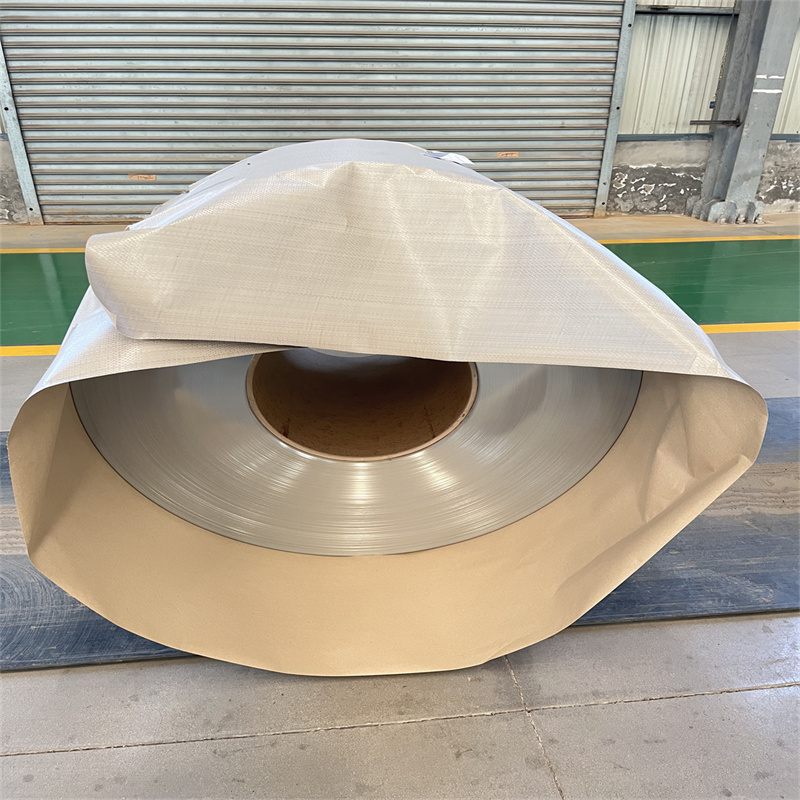

galvanized iron tube manufacturers

The Rise of Galvanized Iron Tube Manufacturers

In recent years, the construction and manufacturing industries have experienced a surge in demand for galvanized iron tubes. Known for their durability, resistance to corrosion, and versatility, galvanized iron tubes have become a staple in various applications, from building frameworks to plumbing and fencing. This article delves into the role of galvanized iron tube manufacturers, their contributions to the industry, and the advantages of using galvanized iron tubes.

Galvanized iron tubes are made by coating iron or steel with a layer of zinc. This process not only enhances the material's longevity but also provides a protective barrier against rusting and corrosion, particularly in harsh environmental conditions. The growing urbanization and industrialization around the world have spurred a need for reliable construction materials, and galvanized iron tubes have emerged as a popular choice due to their strength and resilience.

Manufacturers of galvanized iron tubes are pivotal in meeting this rising demand. They employ state-of-the-art technology and innovative techniques to produce high-quality tubing that adheres to international standards. This has led to an increase in competition among manufacturers, resulting in improved product offerings and lower prices. Many manufacturers have also adopted sustainable practices in their production processes, such as recycling waste materials and reducing energy consumption, in line with global sustainability trends.

galvanized iron tube manufacturers

The applications of galvanized iron tubes are extensive. In the construction industry, they are used for structural support in buildings and bridges, as well as for scaffolding and safety rails. In plumbing, these tubes provide reliable piping solutions for water supply and sewage systems. Additionally, they are commonly used for manufacturing fences, gates, and other outdoor structures due to their excellent weather resistance. Their versatility makes them an essential component in many sectors, including agriculture, automotive, and electrical.

One of the significant advantages of using galvanized iron tubes is their cost-effectiveness. Although the initial investment may be slightly higher than that of non-galvanized options, the long-term benefits are undeniable. The extended lifespan of galvanized tubes reduces the need for frequent replacements, maintenance, and repairs, resulting in significant savings over time. Moreover, the protective zinc coating allows these tubes to maintain their structural integrity even in challenging environments, making them a practical choice for builders and manufacturers alike.

Another key advantage is the ease of installation and fabrication. Galvanized iron tubes can be easily cut, welded, and joined with other materials, allowing for flexibility in design and application. This adaptability not only streamlines the construction process but also enables engineers and architects to create innovative solutions tailored to specific needs.

In conclusion, the role of galvanized iron tube manufacturers is crucial in shaping the future of construction and manufacturing industries. By providing high-quality, durable, and versatile products, these manufacturers contribute significantly to improving infrastructure and overall safety. As the world continues to evolve, the demand for robust materials like galvanized iron tubes will only grow, ensuring that these manufacturers remain at the forefront of industrial development. Whether used in large-scale construction projects or everyday applications, galvanized iron tubes offer a reliable and economical solution that stands the test of time.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025