Nov . 02, 2024 02:38 Back to list

galvanised roof sheet factories

A Comprehensive Look at Galvanised Roof Sheet Factories

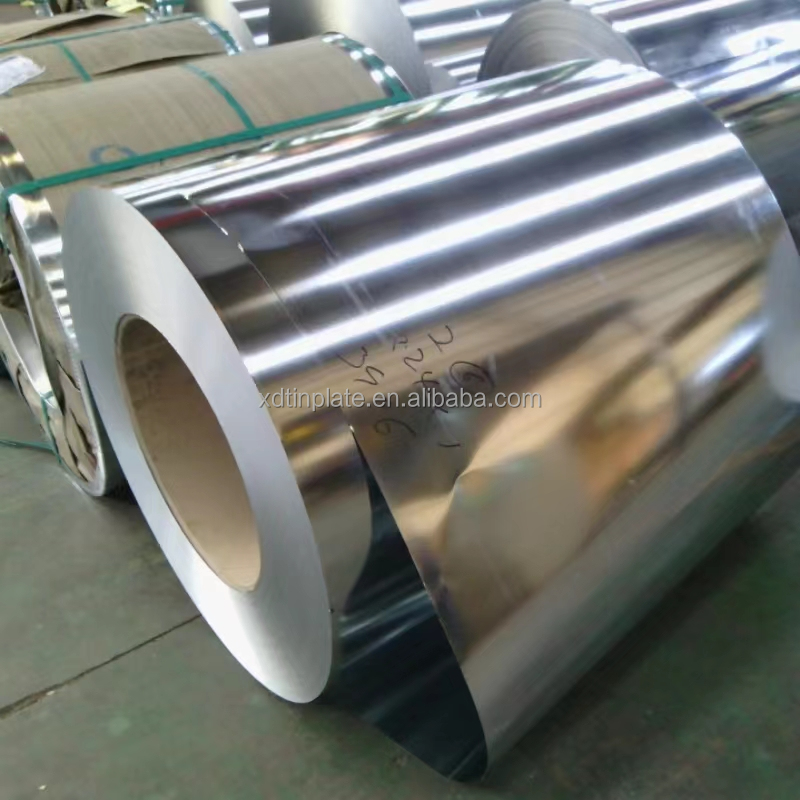

Galvanised roof sheets have become an essential material in modern construction, providing durability, strength, and protection against adverse weather conditions. As industrialization continues to surge globally, the demand for high-quality roofing solutions has led to the growth of galvanised roof sheet factories. This article delves into the significance of these factories, the manufacturing process, and their impact on the construction industry.

Galvanisation is a process that involves coating steel sheets with zinc to prevent corrosion. This method significantly extends the lifespan of roofing materials and maintains their structural integrity. Galvanised roof sheets are particularly popular in areas prone to harsh weather conditions, including heavy rainfall, high winds, and extreme temperatures. The protective layer of zinc shields the steel from rust, thereby reducing maintenance costs and ensuring long-lasting performance.

The manufacturing process of galvanised roof sheets involves several steps. First, high-quality steel is selected and rolled into sheets of varying thicknesses. These sheets are then cleaned to remove impurities, preparing them for the galvanisation process. Once cleaned, the sheets are immersed in a bath of molten zinc, which adheres to the surface and forms a robust protective coating. After galvanisation, the sheets are cooled and further processed to achieve the desired dimensions and finishes.

galvanised roof sheet factories

Efficient production techniques are vital for ensuring the quality and affordability of galvanised roof sheets. Many factories have adopted advanced technologies, such as automated production lines and robotic handling systems, to enhance productivity and minimize human error. These innovations not only streamline the manufacturing process but also contribute to improved safety standards within the factories.

One of the key benefits of galvanised roof sheet factories is their positive impact on the environment. The recycling of steel is a crucial aspect of the manufacturing process, as it reduces the need for virgin materials, thereby conserving natural resources. Additionally, the longevity of galvanised sheets means that they need to be replaced less frequently, resulting in reduced waste. Many factories are also implementing sustainable practices, such as using eco-friendly coatings and reducing energy consumption, to further minimize their ecological footprint.

The economic significance of galvanised roof sheet factories cannot be overstated. They create numerous jobs, both directly within the factories and indirectly through the supply chain. Additionally, by producing high-quality roofing materials, these factories contribute to the growth of the construction industry, enabling the development of residential, commercial, and industrial projects.

In conclusion, galvanised roof sheet factories play a crucial role in meeting the evolving needs of the construction industry. The combination of advanced manufacturing processes, environmental responsibility, and economic contribution makes these factories indispensable. As the demand for reliable and durable roofing solutions continues to rise, the galvanised roof sheet industry is poised for further growth and innovation, ensuring that builders have access to top-quality materials for their projects. Investing in such facilities not only supports local economies but also promotes sustainable practices in the construction sector.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025