نوامبر . 08, 2024 14:36 Back to list

roof metal sheet size factory

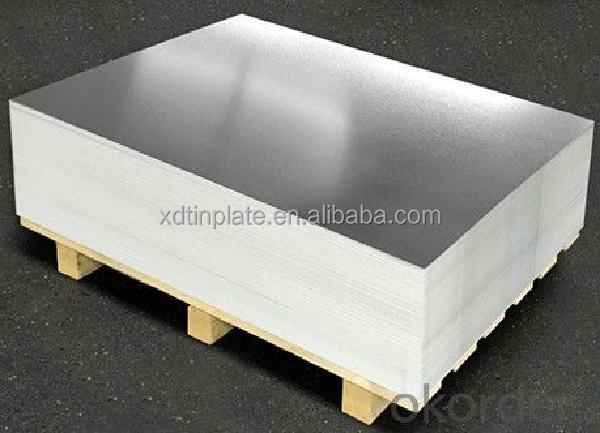

Understanding Roof Metal Sheet Size A Comprehensive Guide for Factory Operations

When it comes to roofing solutions, metal sheets have gained significant popularity due to their durability, aesthetics, and ease of installation. For factories and manufacturers specializing in metal roofing, understanding the various sizes of metal sheets is crucial for both production efficiency and meeting customer needs. In this article, we will explore the importance of roof metal sheet sizes, their standard measurements, and how factories can optimize their operations.

The Importance of Metal Sheet Size

The size of metal sheets plays a critical role in various aspects of roofing projects. One of the primary factors affecting the choice of size is the type of building. Different structures, be it residential, commercial, or industrial, will demand different formats and dimensions based on architectural designs and safety standards. Additionally, the size of a metal sheet can impact the installation process. Larger sheets can help reduce the number of seams, minimizing the potential for leaks and enhancing the overall integrity of the roof.

Standard Sizes of Metal Sheets

Metal roofing sheets come in a variety of sizes, typically measured in width and length. The most common widths range from 24 to 36 inches, while lengths can vary significantly based on specific requirements, often extending up to 20 feet or more. The most popular thickness for metal roofing materials is between 26 and 29 gauge. However, thicker options may be available for projects requiring increased strength or load-bearing capacity.

In factories, standardizing sheet sizes can streamline the production process. For example, a factory that produces metal sheets exclusively in 36-inch widths can establish efficient cutting and manufacturing processes, ultimately reducing labor and material costs. In contrast, offering a wider range of sizes can cater to diverse customer needs but may complicate inventory management.

Factors Influencing Metal Sheet Size Selection

Several factors can influence the selection of metal sheet size, including

roof metal sheet size factory

1. Building Design The architectural design of a building often dictates the dimensions of the roofing materials. Custom sizes may be requested to fit specific angles or curvatures.

2. Local Regulations Building codes and regulations can specify certain sizes that must be adhered to, depending on the region and type of structure.

3. Functional Requirements The intended use of the building might require specific sheet sizes for insulation, ventilation, or load-bearing purposes.

4. Aesthetic Considerations The exterior appearance of the building can also affect size choices, as some designs may call for larger or longer sheets to achieve a seamless look.

Optimizing Factory Operations

To optimize operations, factories should focus on inventory management and production efficiency. Implementing a just-in-time (JIT) inventory system can help reduce waste and costs by ensuring materials are only produced as needed. Utilizing CAD (computer-aided design) software can also aid in precise cutting measurements, minimizing scrap and maximizing yield from raw materials.

Additionally, factories can benefit from training employees on the significance of metal sheet sizes and their impact on overall quality and customer satisfaction. By fostering a thorough understanding of these factors among staff, production lines can run more smoothly, and product quality can be enhanced.

Conclusion

Understanding roof metal sheet sizes is essential for factories involved in metal roofing production. With the right knowledge and systems in place, manufacturers can meet customer demands while optimizing their production processes. By focusing on standard sizes, managing inventory effectively, and training staff, factories can position themselves as industry leaders in the competitive roofing market. As buildings continue to evolve, so will the need for innovative and high-quality metal roofing solutions, making it imperative for factories to stay ahead of the curve.

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025

-

Used BMW 1 Series Cars Luxury Performance & Value Deals

NewsJun.10,2025

-

Wuling Mini EV X2 Price in Malaysia Compact EV Specs

NewsJun.09,2025

-

Should You Buy a Used Rental Car? Save Money & Trusted Quality

NewsJun.09,2025