Dic . 14, 2024 03:03 Back to list

Roof Slip Sheet Manufacturing for Enhanced Protective Solutions in Construction Industry

Understanding Roof Slip Sheets A Comprehensive Overview of the Factory Processes

Roof slip sheets play a critical role in various construction and industrial applications. These sheets are designed to facilitate the safe and efficient movement of materials, particularly those involving roofing systems. In this article, we will delve into the manufacturing processes of roof slip sheets and explore the significance of factories specializing in their production.

What Are Roof Slip Sheets?

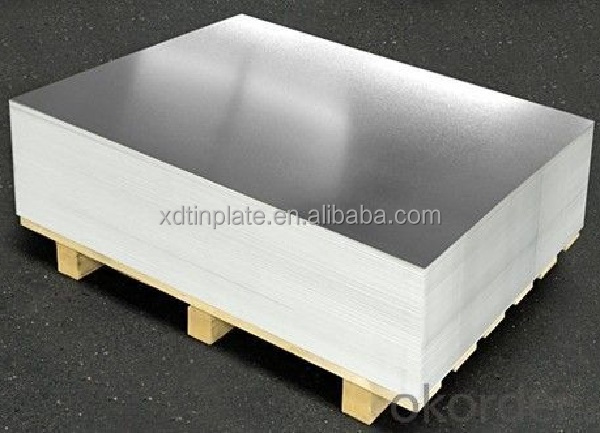

Roof slip sheets are thin layers of material used primarily to provide a barrier between different surfaces during construction or material handling. They are typically made from lightweight, durable materials such as polyethylene, polypropylene, or other synthetic films. The main purpose of these sheets is to reduce friction and prevent sticking between surfaces, ensuring that materials can be moved more easily and without damage.

The Importance of Roof Slip Sheets in Construction

In construction, roof slip sheets are essential for protecting sensitive materials from moisture, debris, and other potential contaminants. When roofing materials need to be transported or stored, slip sheets help maintain their quality, ensuring that they remain intact and functional when it's time for installation. Additionally, these sheets can aid in the organization of materials on-site, improving efficiency and reducing waste.

Manufacturing Process of Roof Slip Sheets

The manufacturing of roof slip sheets involves several critical steps. Factories that specialize in these products employ advanced technologies and adhere to stringent quality control measures to ensure that the final product meets industry standards.

1. Material Selection The first step in the manufacturing process is the selection of the appropriate material. Factories typically choose high-quality, durable plastics that can withstand various environmental conditions. The choice of material is crucial as it directly impacts the performance and longevity of the slip sheets.

roof slip sheet factory

2. Extrusion Once the material has been selected, it is fed into an extrusion machine. In this process, the plastic is melted and formed into thin sheets. The extrusion process must be carefully controlled to ensure uniform thickness and consistent quality across the entire surface area.

3. Printing and Coating After the sheets are extruded, they may undergo printing or coating processes. Printing can be used to add logos, handling instructions, or other necessary information, while coatings might be applied to enhance slip resistance or weather protection.

4. Cutting and Packaging Once the sheets have been printed and coated, they are cut to the desired dimensions. Factories often produce roof slip sheets in various sizes to meet the diverse needs of their customers. After cutting, the sheets are packaged for distribution, ensuring they remain safe and undamaged during transport.

Quality Control and Sustainability

Quality control is an integral part of the manufacturing process. Factories implement rigorous testing protocols to ensure that each batch of slip sheets meets the necessary specifications for strength, durability, and slip resistance. This attention to detail helps guarantee customer satisfaction and product reliability.

Moreover, many manufacturers are becoming increasingly aware of their environmental impact. Sustainable practices, such as using recycled materials and reducing waste during production, are becoming more commonplace in factories producing roof slip sheets.

Conclusion

In conclusion, roof slip sheets are crucial components in the construction industry, facilitating the safe and efficient handling of materials. The manufacturing process of these sheets involves careful selection of materials, precision in extrusion, and stringent quality control measures. As the demand for efficient building solutions continues to grow, so too will the importance of factories that specialize in the production of high-quality roof slip sheets. By understanding the processes and significance of these sheets, stakeholders can better appreciate their role in modern construction practices.

-

Affordable Used Car Engines Prices Quality Used Car Engines for Sale Reliable Used Engines

NewsJul.08,2025

-

Can You Use Dish Soap on Cars? Discover Safe Car Cleaning Alternatives

NewsJul.08,2025

-

Top Car and Driver EV SUV Picks Best Electric SUVs 2023, Ratings & Reviews

NewsJul.07,2025

-

How to Buy Used Cars Cheap Best Places & Top Deals for Affordable Vehicles

NewsJul.07,2025

-

Best Danbury Used Cars for Sale Reliable Used Cars Danbury CT Dealer Ingersoll Auto Specials

NewsJul.06,2025

-

Quality Used Car Parts in Asheville Affordable Asheville NC Auto Parts Reliable Asheville Used Car Dealerships

NewsJul.06,2025