Nov . 03, 2024 17:13 Back to list

galvanized iron sheet price supplier

Understanding the Pricing of Galvanized Iron Sheets A Supplier's Perspective

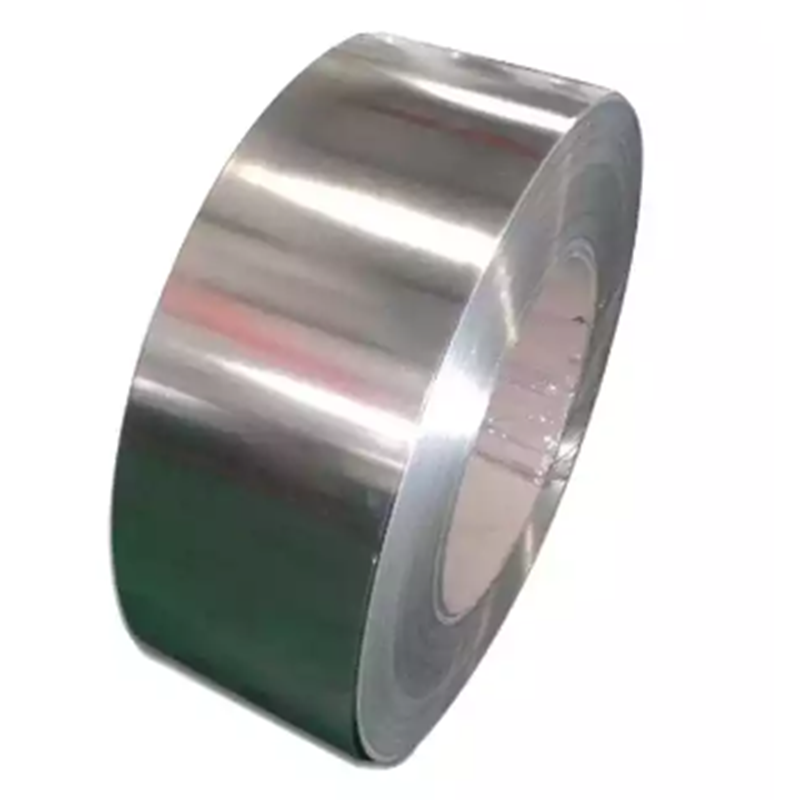

Galvanized iron sheets have become a popular choice in various industries, thanks to their corrosion resistance and durability. As a supplier of galvanized iron sheets, it is crucial to understand the factors that influence their pricing to maintain competitiveness in the market and ensure customer satisfaction.

One of the primary factors affecting the price of galvanized iron sheets is the cost of raw materials. Zinc, used in the galvanizing process, significantly impacts the overall cost. Fluctuations in the global zinc market can lead to variations in pricing, which suppliers must monitor closely. Additionally, the base steel price also plays a vital role, as it constitutes the majority of the sheet's composition. Suppliers should keep track of steel market trends to adjust their pricing strategies accordingly.

Another important factor is the manufacturing process. The method of galvanization, whether hot-dip or electro-galvanization, influences the quality and price of the sheets. Hot-dipped galvanized sheets typically offer better protection against corrosion, which can justify a higher price point. Suppliers must educate their customers about these differences to help them make informed purchasing decisions.

galvanized iron sheet price supplier

The size and thickness of galvanized iron sheets also affect pricing

. Custom cut sizes or thicker sheets can incur additional processing costs, leading to higher prices. As a supplier, offering a variety of sizes and thicknesses can cater to a broader customer base, but it's essential to be transparent about how these options affect pricing.Market demand and supply dynamics also play a crucial role in pricing. During construction booms or increased demand for industrial applications, prices may rise due to limited supply. Conversely, during economic downturns, excess supply may lead to price reductions. Suppliers must be agile and responsive to these market changes to maintain their competitive edge.

Finally, geographical factors can influence pricing. Shipping costs, local regulations, and tariffs can all impact the final price of galvanized iron sheets. Suppliers need to consider these aspects when setting their prices to ensure they remain attractive to potential buyers.

In conclusion, pricing galvanized iron sheets involves a complex interplay of various factors, including raw material costs, manufacturing processes, size and thickness, market dynamics, and geographical considerations. By understanding these elements, suppliers can better navigate the market and provide competitive pricing while meeting the needs of their customers.

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025