Dic . 05, 2024 17:36 Back to list

Galvanized Iron and Mild Steel Manufacturing Facility Overview and Production Insights

The Significance of Galvanized Iron and Mild Steel in Manufacturing

In the realm of construction and manufacturing, galvanized iron and mild steel play crucial roles due to their unique properties and versatility. Factors such as strength, ductility, and corrosion resistance make these materials invaluable across various industries. This article explores the significance of galvanized iron and mild steel, their manufacturing processes, and their applications.

Understanding Galvanized Iron and Mild Steel

Galvanized iron is essentially iron or steel that has been coated with a layer of zinc to prevent corrosion. This protective coating makes it ideal for use in environments where exposure to moisture and air could lead to rust formation. The process of galvanization involves dipping the iron or steel into molten zinc or applying the zinc through electroplating. This results in a durable finish that can withstand harsh weather conditions, making galvanized iron a preferred choice in outdoor applications.

Mild steel, or low-carbon steel, contains a carbon content of up to 0.25%. This composition grants mild steel excellent malleability and ductility, allowing it to be easily shaped and formed into various products. Unlike galvanized iron, mild steel does not contain a protective layer of zinc; hence, it is more susceptible to corrosion. However, its strength and cost-effectiveness make it a favored material in construction and manufacturing sectors.

Manufacturing Processes and Techniques

The production of galvanized iron begins with the base material, which is usually hot-rolled or cold-rolled steel. The steel is cleaned to remove any rust, oil, or scale, which ensures proper adhesion of the zinc coating. The cleaning process often involves pickling, wherein the steel is immersed in an acid solution, followed by rinsing and drying.

Once cleaned, the steel undergoes the galvanization process. Hot-dip galvanization is the most common method; the steel is immersed in molten zinc, which bonds with the iron to create a robust coating. The coated product is then cooled and inspected for quality control.

For mild steel, the manufacturing process primarily involves rolling and shaping. The raw materials, in the form of iron ore, are smelted in a blast furnace to produce pig iron. This pig iron is then converted into mild steel through processes such as oxygen blowing and refining. The final product can be fabricated through welding, bending, and cutting, making mild steel incredibly versatile for different applications.

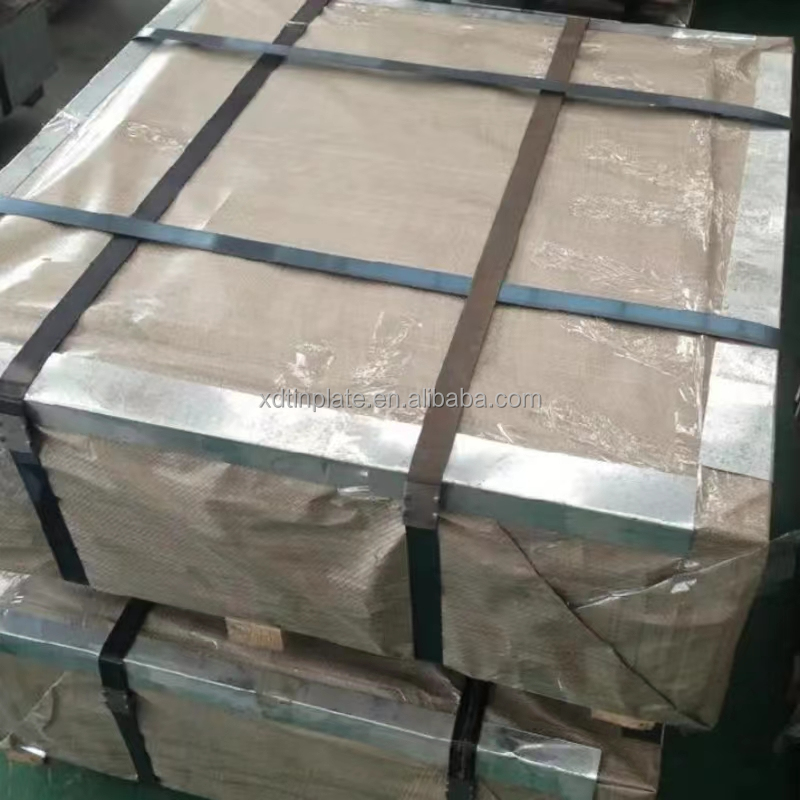

galvanized iron mild steel factory

Applications Across Industries

Galvanized iron and mild steel are utilized across numerous industries due to their specific properties. Galvanized iron is extensively used for construction materials such as roofing sheets, gutters, and fencing. Its corrosion-resistant nature ensures longevity, significantly reducing maintenance costs over time.

In the automotive industry, mild steel is commonly used for manufacturing car bodies, frames, and components. Its excellent tensile strength supports the structural integrity required for vehicle safety. Additionally, mild steel's welded joints provide durability and flexibility in design, enabling manufacturers to produce diverse automotive models.

Moreover, galvanized iron is also prevalent in the agriculture sector. It is used for constructing barns, silos, and irrigation systems, where exposure to environmental elements is a concern. The durability of galvanized iron in agricultural settings helps farmers maintain their equipment and structures, ensuring operational efficacy.

Environmental Considerations

The advantages of using galvanized iron and mild steel extend beyond performance; these materials can also contribute to sustainability. The recycling of both steel materials is an important practice in reducing waste and conserving resources. Steel is one of the most recycled materials globally, with a recycling rate of up to 85%. This aspect not only promotes environmental conservation but also contributes to a circular economy where materials are reused and repurposed.

Conclusion

Galvanized iron and mild steel are indispensable materials in the manufacturing and construction industries. Their unique properties offer numerous advantages that cater to a diverse range of applications, from construction to automotive manufacturing. As industries continue to innovate and evolve, the demand for these materials remains robust, highlighting their lasting significance in modern manufacturing. With ongoing advancements in technology and manufacturing processes, the future of galvanized iron and mild steel looks promising, paving the way for even more versatile and sustainable applications in various sectors.

-

Best PA Used Cars for Sale Reliable Ready Credit & Pyramid Used Cars Mike Hill Used Cars Deals

NewsJul.04,2025

-

Car Parts Used Auto Parts Market – Affordable & Quality Car-Parts.com Selection

NewsJul.04,2025

-

Best Used Cars Kalamazoo Affordable & Reliable Vehicles for Sale in Michigan

NewsJul.04,2025

-

Affordable Insurance for Used Cars – Compare Used vs New Car Insurance & Save

NewsJun.10,2025

-

Find Quality Ancira Boerne Used Cars Affordable, Reliable Pre-Owned Vehicles for Every Lifestyle

NewsJun.10,2025

-

Affordable Used Cars St Augustine FL Toyota Deals & Savings

NewsJun.10,2025