Nov . 05, 2024 14:44 Back to list

galvanized iron coil factory factories

The Role of Galvanized Iron Coil Factories in Modern Industry

Galvanized iron coil factories play a crucial role in the manufacturing landscape, supplying a versatile and durable material that is essential for a wide array of applications. Galvanization, the process of coating iron or steel with a layer of zinc, provides enhanced protection against corrosion, making it ideal for both industrial and consumer products. This article will explore the significance of galvanized iron coils, the manufacturing process, and the impact these factories have on various sectors.

Understanding Galvanized Iron Coils

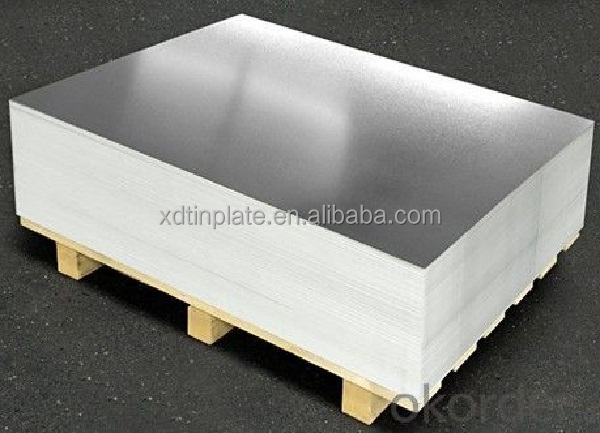

Galvanized iron coils are primarily used in construction, automotive, appliance manufacturing, and packaging industries. The coils are made from rolled steel sheets that undergo galvanization to ensure longevity and resistance to environmental elements. Due to its unique properties, galvanized iron is particularly valued for outdoor structures, roofing systems, water pipes, and even furniture. The process of galvanization not only improves the durability of the metal but also enhances its appearance, making it a popular choice for aesthetic applications.

The Manufacturing Process

The journey of a galvanized iron coil begins with the preparation of the base metal. Hot-rolled or cold-rolled steel is the primary material used in the production of galvanized coils. The steel undergoes a thorough cleaning process to remove any impurities, such as rust or oils, that may interfere with the adhesion of the zinc coating.

Once the steel is prepped, it is immersed in a molten bath of zinc at high temperatures, typically around 450°C (840°F). This process can be achieved through two main methods hot-dip galvanizing and electro-galvanizing. In hot-dip galvanizing, the steel is submerged in the zinc bath, resulting in a thick, robust coating. Alternatively, electro-galvanizing utilizes an electric current to deposit a thin layer of zinc on the surface of the steel. While the latter method yields a smoother finish, it may not offer the same level of corrosion resistance as hot-dip galvanizing.

After the zinc application, the coils undergo cooling and curing processes to ensure the coating adheres properly. Finally, the galvanized sheets are rolled into coils, making them easy to transport and handle for manufacturers.

galvanized iron coil factory factories

Economic and Environmental Considerations

Galvanized iron coil factories contribute significantly to the economy by providing jobs and supporting local economies in manufacturing regions. The demand for galvanized steel products continues to rise due to their enhanced properties, which often lead to cost savings over time. For instance, structures made with galvanized materials tend to have lower maintenance costs due to their resistance to rust and corrosion.

Moreover, the manufacturing process has also evolved to become more environmentally friendly. Modern galvanization techniques employ advanced technologies that minimize waste and reduce energy consumption. For example, some factories use recycled materials in their production processes, promoting sustainability and reducing the carbon footprint associated with raw material extraction and processing.

Applications Across Industries

The applications of galvanized iron coils are extensive. In construction, they are utilized for roofing sheets, wall panels, and structural components. The automotive industry benefits from galvanized steel for car bodies and frames due to its weight-saving properties and improved safety features.

In the appliance sector, galvanized components are commonly found in refrigerators, air conditioning units, and washing machines, where moisture resistance is crucial. Packaging industries also rely on galvanized steel for the production of cans and containers, ensuring product longevity and preserving quality.

Conclusion

Galvanized iron coil factories are fundamental to modern manufacturing, driving innovation while meeting the increasing demand for durable and corrosion-resistant materials. As industries evolve, these factories will continue to adapt, embracing new technologies and sustainable practices. The importance of galvanized iron coils extends beyond mere functionality; they represent a commitment to quality and efficiency in various applications, shaping the future of manufacturing and construction around the globe. As such, the ongoing investment in these factories is vital for supporting economic growth and technological advancement across multiple sectors.

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025