Ene . 02, 2025 20:31 Back to list

cost to install sheet metal roof factory

Understanding the Cost to Install Sheet Metal Roofs in Factories

When considering a roofing solution for industrial facilities, sheet metal roofing often emerges as a preferred option. This popularity is driven by several factors, including durability, energy efficiency, and aesthetic versatility. However, one of the foremost considerations for factory owners is the cost to install a sheet metal roof. This article will explore the various aspects that contribute to the total installation cost, ensuring that factory managers can budget appropriately while making informed decisions.

1. Material Costs

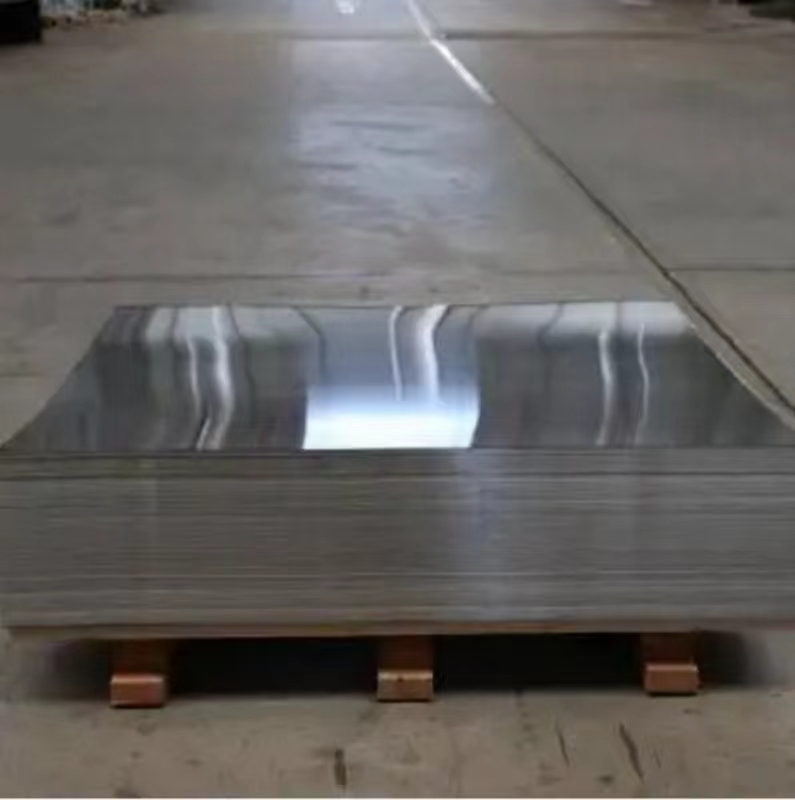

The primary component of any roofing installation is the material itself. Sheet metal roofing is generally made from various metals such as aluminum, steel, or copper. The choice of material significantly impacts the overall cost. For instance, while aluminum is lightweight and resistant to corrosion, leading to lower long-term maintenance costs, it can be more expensive upfront than galvanized steel. The thickness and coating of the metal also influence pricing. Thicker sheets and those with protective coatings to enhance durability and energy efficiency typically come at a premium.

2. Labor Costs

Labor costs can vary widely depending on several factors, including geographic location, labor market conditions, and the complexity of the installation. Experienced contractors can charge more, but their expertise may lead to a superior install that could save money in repairs and maintenance later. It's essential to obtain multiple quotes from qualified roofing contractors to compare rates and services offered. Consider also that installation in adverse weather conditions or difficult-to-access areas (like high roofs or tightly spaced facilities) may increase labor costs due to the need for special equipment or additional safety precautions.

3. Size and Scope of the Project

The total area of the roof is a critical factor in determining installation costs. Larger roofs not only require more materials but may also necessitate additional structural support or reinforcement, particularly if the existing roof is not adequately equipped to bear the weight of the new sheet metal roofing. Calculating the square footage accurately, along with potential waste factor, is crucial for estimating material needs and costs.

cost to install sheet metal roof factory

4. Additional Features and Accessories

Many factory managers opt for additional features that can add to the overall cost, including insulation, ventilation systems, or high-performance finishes that improve energy efficiency. Insulation can significantly enhance energy savings, especially in facilities that need temperature control for machinery or products. Additionally, features such as gutters, downspouts, and flashing to prevent leaks can also add to expenses but are crucial for effective water management.

5. Regulatory Costs

Depending on the region, there may be municipal or state building codes that must be followed, which can result in additional costs for permits or inspections. It's essential to factor in these potential expenses when budgeting for a roofing project.

6. Long-Term Value

Although the initial installation cost of a sheet metal roof can be higher than traditional options such as asphalt shingles, the long-term value often justifies this investment. Sheet metal roofs are known for their longevity, with lifespans often exceeding 50 years with proper maintenance. Additionally, their reflective surface can lead to energy savings by reducing cooling costs, making them an economical choice in the long run.

Conclusion

Understanding the costs associated with installing a sheet metal roof in a factory setting is crucial for effective budgeting and planning. While it can involve a higher initial investment compared to other roofing options, the durability, energy efficiency, and potential long-term savings make it a compelling choice for industrial facilities. Factory owners should engage with knowledgeable roofing contractors, consider the variety of materials available, assess their specific needs, and meticulously account for labor, additional features, and regulatory compliance to make well-informed decisions. Investing in a quality sheet metal roof can ultimately ensure that factories remain functional, efficient, and protected for decades to come.

-

Discover Cheap Cars with GPT-4 Turbo Deals | Save Big Now

NewsAug.04,2025

-

Cost-Effective Tram: GPT-4 Turbo AI Savings

NewsAug.03,2025

-

New Energy Vehicles with GPT-4 Turbo AI

NewsAug.02,2025

-

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

GPT-4 Turbo New Energy Vehicles: AI-Driven Efficiency & Smart Mobility

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025