dec . 30, 2024 18:05 Back to list

tin can lids manufacturer

The Importance of Tin Can Lids Manufacturers in the Packaging Industry

In the modern manufacturing landscape, the role of tin can lids manufacturers is pivotal to various sectors such as food and beverage, pharmaceuticals, and household products. As these industries continue to evolve, the demand for high-quality, reliable, and innovative tin can lids has surged, establishing manufacturers as crucial players in the supply chain.

Tin can lids are essential components of canned products, providing a secure seal that preserves the contents and ensures longevity. The need for durable and effective sealing solutions has driven manufacturers to focus on advanced technologies and practices that enhance the integrity of their products. With an increasing emphasis on sustainability, many manufacturers are also investing in eco-friendly materials and production processes that reduce waste and environmental impact.

Quality and Safety Standards

Manufacturers of tin can lids are required to adhere to stringent quality and safety standards. These standards ensure that the lids are not only effective in sealing cans but also safe for food contact. Regulatory agencies such as the Food and Drug Administration (FDA) in the United States oversee these practices, establishing guidelines that manufacturers must follow. It is essential for manufacturers to possess certifications and demonstrate their compliance with health and safety regulations to assure consumers and businesses alike of the quality of their lids.

Innovations in materials and production techniques have led to significant advancements in the durability and functionality of tin can lids. Many manufacturers are now using advanced coatings and materials that enhance corrosion resistance, reduce leaching, and prolong shelf life. As consumer awareness about food safety and preservation increases, manufacturers are continually iterating their designs to meet these demands.

Impact of Technology

tin can lids manufacturer

The integration of technology in tin can lid manufacturing has transformed traditional practices. Automation and precision engineering have allowed for increased efficiency, reduced production costs, and improved consistency in product quality. Modern production facilities utilize sophisticated machinery that can produce large quantities of lids while maintaining strict quality control.

Additionally, technology has enabled manufacturers to implement better tracking and traceability in their supply chains. This is important not just for regulatory compliance, but also for increasing transparency and trust with consumers. By utilizing data analytics and real-time monitoring systems, manufacturers can ensure that their products meet the highest standards and address any potential issues swiftly.

Environmental Considerations

As global awareness of environmental issues grows, tin can lids manufacturers are increasingly focusing on sustainability. Many companies are experimenting with alternative materials, including recyclable and biodegradable options that minimize the ecological footprint of their products. Furthermore, advancements in manufacturing processes aim to reduce energy consumption and waste production.

The recycling of tin can lids is another area of focus. Unlike plastic, metal, including tin, can be recycled indefinitely without losing quality. This creates an opportunity for manufacturers to promote recycling initiatives, educating consumers about the benefits of recycling tin cans and lids to contribute towards a more sustainable future.

Conclusion

In conclusion, tin can lids manufacturers are not just suppliers; they are integral to the packaging industry and play a vital role in product safety, innovation, and sustainability. As consumer expectations and environmental concerns evolve, the industry must adapt to new challenges and opportunities. By investing in quality, technology, and sustainability, tin can lids manufacturers can continue to meet the demands of various industries while contributing to a greener planet. With the ongoing advances in manufacturing processes and a commitment to quality and safety, the future of tin can lids looks promising, ensuring that products remain preserved and safe for consumers worldwide.

-

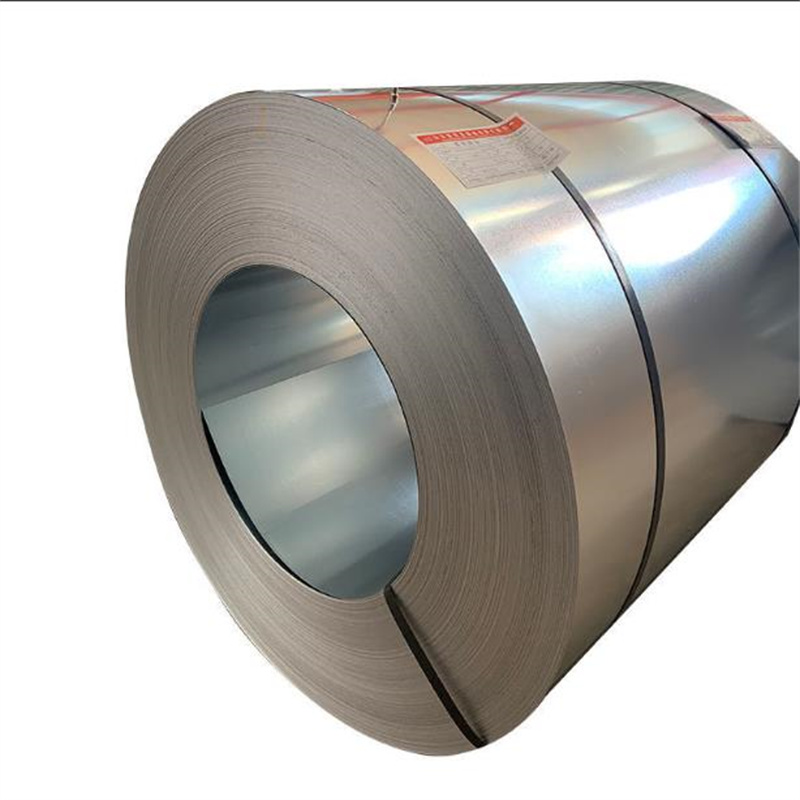

Premium 26 Gauge Galvanized Steel Coil Maker | Quality

NewsJul.31,2025

-

Electric Vehicles for Sale: New Cars, Used Cars & NIO ES8 Offers

NewsJul.30,2025

-

BYD New Energy Vehicles: Innovative New Cars for a Greener Future

NewsJul.29,2025

-

New Energy Vehicle with High Cost Performance & Endurance

NewsJul.29,2025

-

Buy New Car Online – Great Deals & Trusted Used Car Options

NewsJul.29,2025

-

China 14 ft Metal Roofing Price Factory | Durable & Affordable

NewsJul.28,2025